How to install stainless steel perforated sheet

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-05-15 11:25:51 Browse:

Overview of Installation Methods

Welding Installation — Ideal for permanently fixed areas. Offers maximum strength, though weld marks may affect appearance.

Screw Installation — Uses pre‑drilled holes or self‑tapping screws. Quick to install and allows easy removal or replacement.

Embedded Installation — Bends edges into hooks to snap the sheet into slots. Fast, clean, and hardware‑free.

1. Welding Installation

Steps

Positioning

Spot Welding

Perform continuous tack welds every 5–6 cm (approximately 20 mm weld length) to secure the sheet firmly.

Grinding & Corrosion Protection

Smooth out all welds, then apply anti‑corrosion coating on the weld areas to prevent rust.

Pros & Cons

Pros

One‑time installation—highly stable and maintenance‑free.

No periodic tightening required.

Cons

Weld spots can leave slag and discoloration, impacting aesthetics.

Difficult to remove or relocate later.

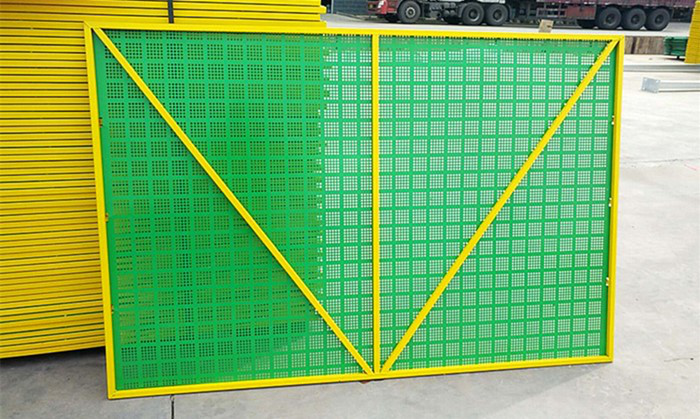

stainless steel perforated sheet

2. Screw Installation

Steps

Pre‑drilling

Factory‑punch holes that match the screw locations.

Fastening

Align the stainless steel perforated sheet with the substrate and drive bolts or self‑tapping screws through the holes until snug.

Inspection

Check each screw’s torque to ensure the sheet is flat and firmly fixed.

Pros & Cons

Pros

No welding equipment needed—quick field work.

Easy to disassemble, replace, or service later.

Cons

Limited fixation points can allow local movement if screws are sparse.

Exposed screw heads may detract from a seamless look.

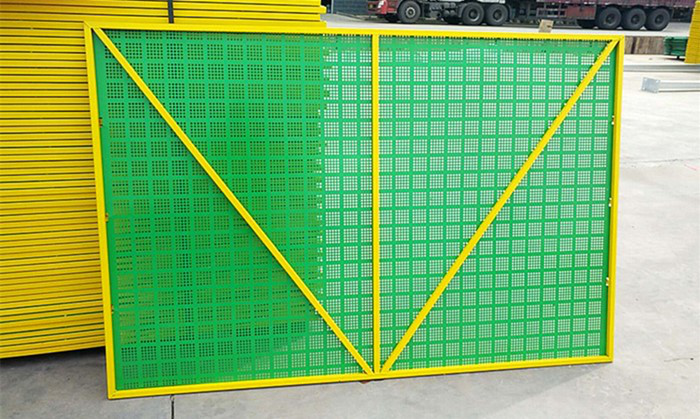

stainless steel perforated sheet

3. Embedded Installation

Steps

Edge Bending

Bend the sheet’s edges into hooks of the required width.

Slotting & Snapping

Insert the hooks into pre‑cut slots, then push to lock the stainless steel perforated sheet in place.

Fine Adjustment

Tap gently with a rubber mallet to eliminate any looseness.

Pros & Cons

Pros

No extra fasteners—cost‑effective and clean finish.

Very fast installation with a smooth, flush surface.

Cons

Precise slot dimensions are critical.

Hook damage complicates future adjustments or replacements.

Conclusion

Choosing the right installation method for your stainless steel perforated sheet depends on load requirements, maintenance frequency, and appearance needs.

Use welding installation where permanent, robust fixation is paramount.

Opt for screw installation when future removal or inspection is anticipated.

Select embedded installation for the highest standards of flush aesthetics and speed.

We hope these guidelines help you achieve a durable, attractive, and easy‑to‑maintain stainless steel perforated sheet installation.