Where Is Stainless Steel Perforated Sheet Used Most? A Detailed Guide

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-11 18:53:46 Browse:

In both modern industry and everyday life, stainless steel perforated sheets have become an indispensable metal material. With excellent mechanical strength, a flat surface, corrosion resistance, and ease of processing, they are widely used in various sectors. This article outlines the most common application areas of stainless steel perforated sheets, helping you better understand their practical value.

1. Mechanical Equipment: Strength Meets Functionality

In the field of mechanical engineering and equipment manufacturing, stainless steel perforated sheets are widely applied. Their functions include:

Protective Covers: Used as machine covers or guards to prevent debris from entering and ensure operator safety, especially in high-temperature, high-pressure, or corrosive environments.

Filter Plates: Serve as filters in gas and liquid systems, removing impurities. Commonly found in petrochemical, chemical, and mining sectors.

Ventilation Panels: The holes allow for airflow and heat dissipation, maintaining the stable operation of machinery.

These applications enhance the lifespan, safety, and operational efficiency of equipment in industrial environments.

Stainless steel perforated sheets are applied in the field of mechanical equipment.

2. Agriculture: Durable Support in Processing Systems

Stainless steel perforated sheets are also vital in agriculture, particularly in the following uses:

Machinery Shields: Used on agricultural equipment to prevent dust and debris buildup while allowing ventilation.

Filtering and Screening: Widely applied in grain sorting, seed cleaning, and feed processing to ensure product quality.

Mill Bottom Supports: Serve as structural bases to aid in material classification and filtering.

Thanks to their corrosion resistance and durability, stainless steel perforated sheets remain reliable under challenging agricultural conditions.

Stainless steel perforated sheets are applied in the field of sieve plates.

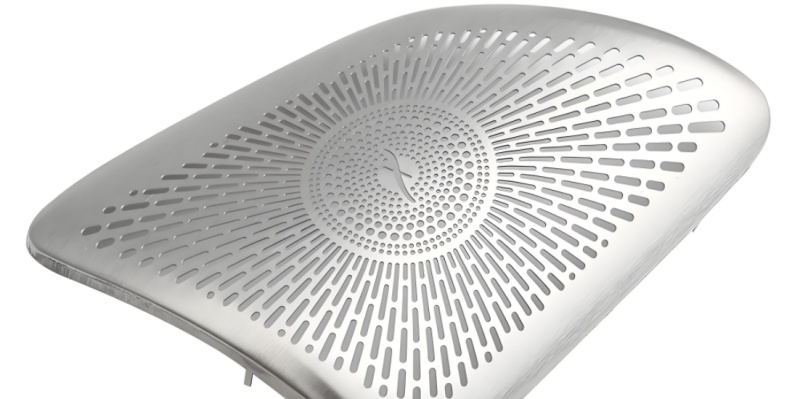

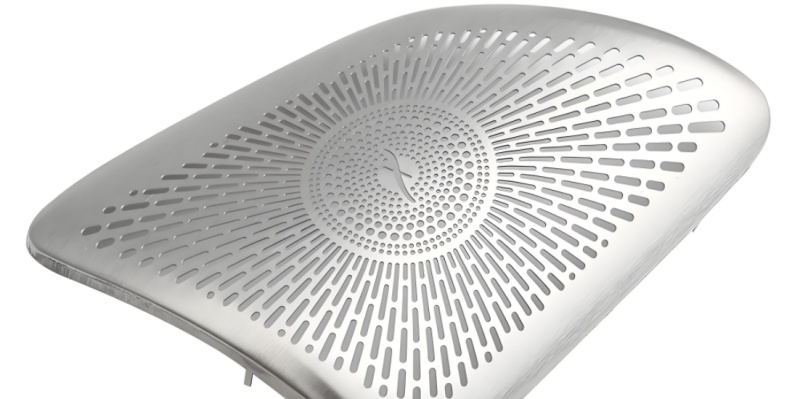

3. Electronics: Protection and Heat Management

Device Casings: Used in computer cases, speaker covers, and mobile devices to provide dust protection and heat dissipation.

Speaker Grilles: Applied to speaker systems to offer acoustic transparency while protecting from physical damage.

Cooling Elements: Facilitate air circulation, helping to manage heat in electronic systems.

Their strength and airflow performance make them ideal for use in electronics manufacturing.

Stainless steel perforated sheets are applied in speaker guards.

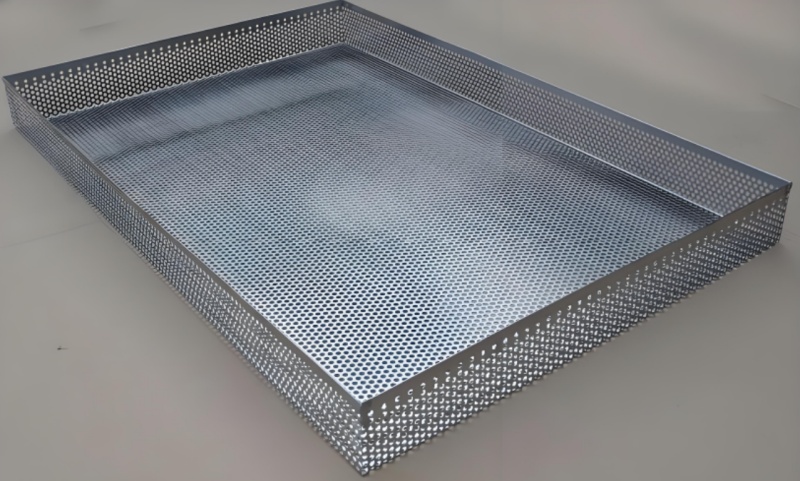

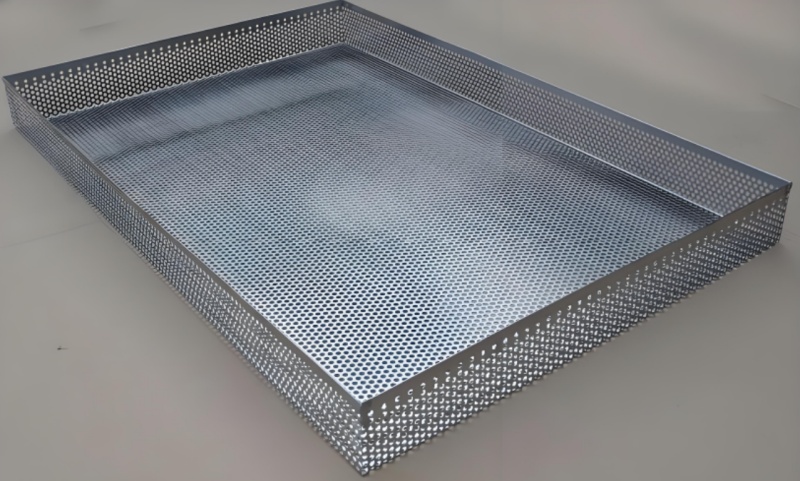

4. Kitchen Equipment: Hygiene Meets High Performance

Kitchens demand materials that are hygienic, heat-resistant, and easy to clean—making stainless steel perforated sheets an excellent choice:

Baking Trays & Racks: Used in ovens to allow even heat distribution and drainage of excess oil or moisture.

Colanders & Strainers: Essential in food rinsing, draining, and filtering applications like washing vegetables or cooking pasta.

Dishwasher Components: Some dishwashers use perforated sheets to separate utensils and improve airflow for better cleaning and drying.

The resistance to corrosion and high temperatures makes these sheets ideal for modern kitchens.

Stainless steel perforated sheets are applied in kitchen baking trays.

5. Automotive Industry: Enhancing Performance and Design

In the automotive sector, stainless steel perforated sheets play multiple functional and aesthetic roles:

Air Intake Grilles: Improve vehicle airflow while contributing to weight reduction.

Exhaust & Muffler Systems: Used in silencer components to absorb sound and reduce engine noise.

Component Protection: Applied to headlight covers, engine guards, and more to combine safety and ventilation.

Their mechanical reliability and versatility are vital for modern vehicle design and manufacturing.

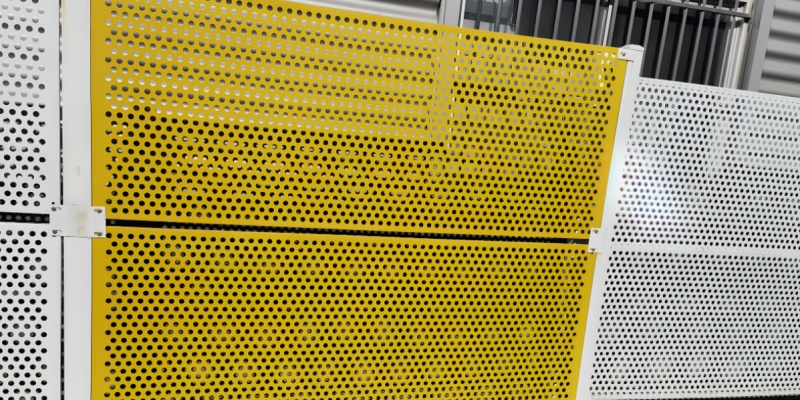

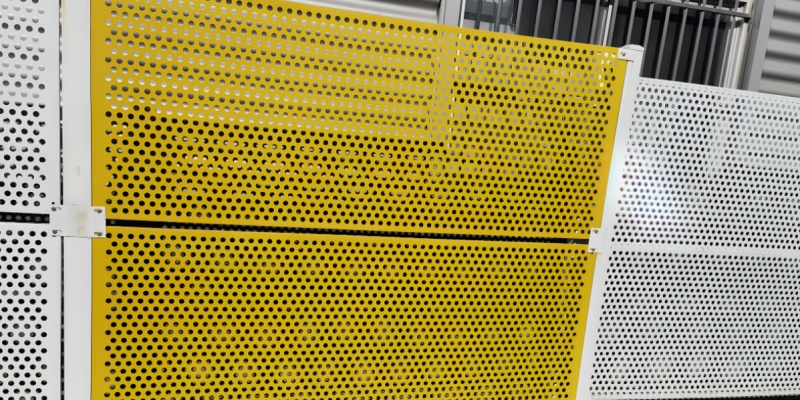

6. Transportation Facilities: Safety with Aesthetic Appeal

Public transportation and infrastructure projects often rely on stainless steel perforated sheets for both functional and decorative purposes:

Decorative Panels: Used in subway stations, airports, and terminals to create a modern, clean look while withstanding wind pressure.

Safety Railings: Installed in walkways, bridges, and stairwells for ventilation and fall protection.

Their aesthetic appearance and structural integrity make them ideal for large-scale infrastructure use.

Stainless steel perforated sheets are applied in road guardrails.

7. Construction Industry: Architectural Style with Structural Strength

In the world of construction and architecture, stainless steel perforated sheets offer a unique blend of form and function:

Building Facades: Act as shading systems and decorative cladding, allowing light transmission while reducing solar exposure.

Ceilings and Partitions: Used in office buildings and homes for suspended ceilings and space dividers with a sleek, modern finish.

Non-slip Flooring & Safety Barriers: Applied to staircases and walkways to prevent slipping and improve safety.

Their visual appeal and physical properties make them a popular choice in modern construction.

8. Arts & Crafts: Turning Functional Metal into Creative Expression

Stainless steel perforated sheets are increasingly being adopted in artistic and creative industries:

Decorative Artwork: Their textures and hole patterns are perfect for producing artistic panels and lighting fixtures.

Custom Home Décor: Used in wall panels, dividers, and custom pieces to add a modern industrial touch.

Exhibition Displays: Ideal for creating eye-catching installations and presentation platforms.

The unique material texture and flexibility offer limitless potential for artistic creation.

Conclusion: The Expanding Potential of Stainless Steel Perforated Sheets

Stainless steel perforated sheets are valued not only for their strength and corrosion resistance but also for their wide-ranging usability. From machinery to agriculture, electronics to architecture, their adaptability is transforming numerous industries. As technology advances and new demands emerge, these perforated metal sheets are expected to play an even more significant role across both industrial and creative sectors.