Common Aluminum Alloys and Their Properties for Aluminum Perforated Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-05-29 15:19:19 Browse:

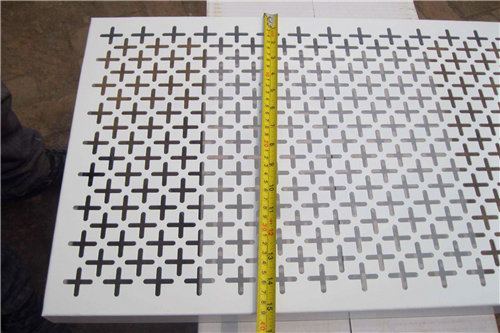

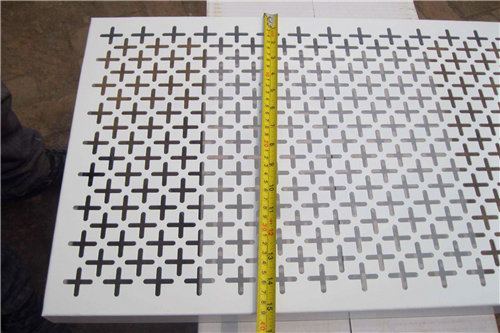

Aluminum Perforated Sheets are widely used in architecture, decoration, and acoustic engineering due to their lightweight nature, high strength, and excellent decorative appeal. Choosing the right aluminum alloy is essential to meet different functional needs. Below are several commonly used aluminum alloys and their key characteristics:

1. 1xxx Series Pure Aluminum (e.g., 1050, 1060)

These alloys feature high purity (≥99.5%), excellent corrosion resistance, and good formability. However, they offer relatively low strength. They are ideal for indoor decorative applications where strength is not a major concern, such as ceilings and wall panels.

2. 3xxx Series Aluminum-Manganese Alloy (e.g., 3003, 3004)

By adding manganese, this series achieves higher strength (tensile strength around 150–200 MPa) and enhanced corrosion resistance. It is commonly used for outdoor facades and sunshades that require moderate structural support.

3. 5xxx Series Aluminum-Magnesium Alloy (e.g., 5052, 5083)

These alloys provide significantly greater strength (tensile strength around 250–350 MPa) and outstanding resistance to marine corrosion. They are suitable for harsh environments such as marine applications, industrial facilities, and chemical plants.

Anodizing

Anodizing creates an oxide layer on the aluminum surface (typically 10–25 μm thick), enhancing hardness (up to HV300) and wear resistance. It also allows for various color finishes, making it ideal for visually prominent architectural uses.

Powder Coating

Powder coating applies a 60–120 μm thick layer using electrostatic techniques, offering excellent UV resistance and a broad color range. It is widely used in airports, train stations, and other outdoor structures.

Material Selection Tips for Aluminum Perforated Sheets

When selecting materials for Aluminum Perforated Sheets, consider the following factors:

Structural Load Requirements: Choose an alloy that meets wind pressure and load-bearing needs.

Acoustic Performance: Select suitable hole patterns and open area ratios based on noise control requirements.

Cost Efficiency: Different alloy series vary in price; align material choice with your budget.

Environmental Conditions: For marine or industrial use, choose alloys with appropriate corrosion resistance.

By selecting the right aluminum alloy and surface treatment, Aluminum Perforated Sheets can deliver both functional and aesthetic performance in your project.