Factors Influencing the Price of Steel Perforated Mesh – A Complete Guide for Buyers

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-07 15:17:59 Browse:

I. Main Factors Influencing the Price of Steel Perforated Mesh

Steel perforated mesh, a widely used metal product in construction, machinery, and decorative applications, varies in price due to multiple factors. This article explores the key variables that impact the cost of perforated metal sheets, helping buyers make informed purchasing decisions.

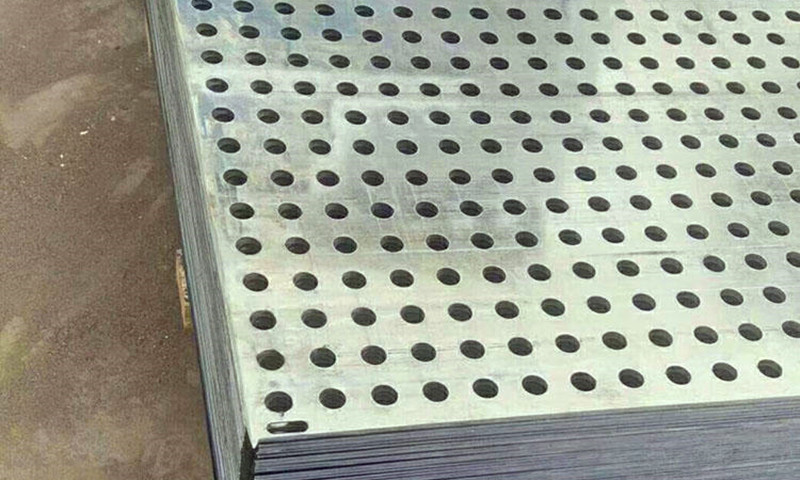

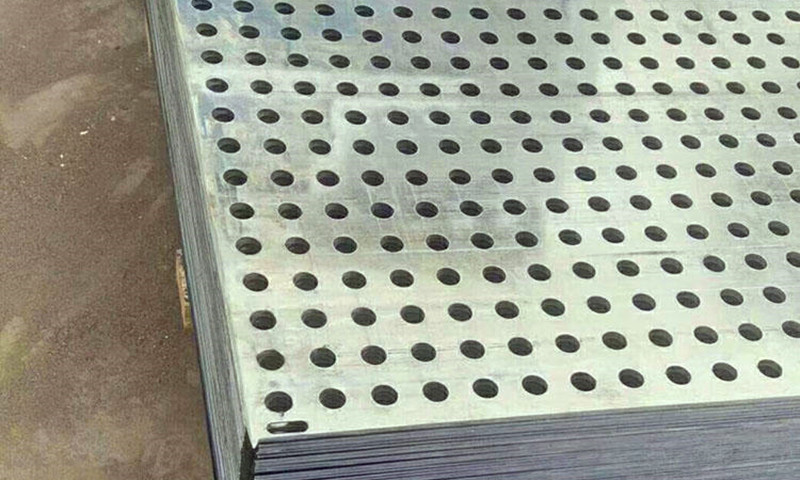

1. Type of Material

The raw material used for perforated metal sheets plays a crucial role in determining cost. Common materials include mild steel, stainless steel, and galvanized steel. Each has different characteristics and price levels:

Mild Steel: Offers lower cost and is suitable for environments where corrosion resistance isn't a major concern.

Stainless Steel: Provides excellent corrosion resistance and aesthetic appeal. It comes at a higher price point, ideal for demanding environments.

Galvanized Steel: A more affordable option than stainless steel, with enhanced anti-rust performance due to the zinc coating.

steel perforated mesh

2. Sheet Thickness

The thickness of the perforated metal sheet directly impacts its strength and durability. Thicker sheets require more material and are generally more expensive. Common thickness ranges from 0.5mm to 10mm, depending on application requirements.

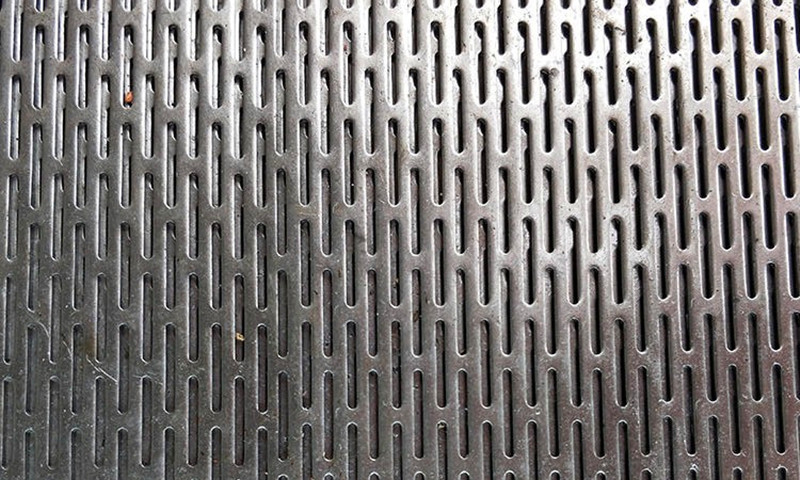

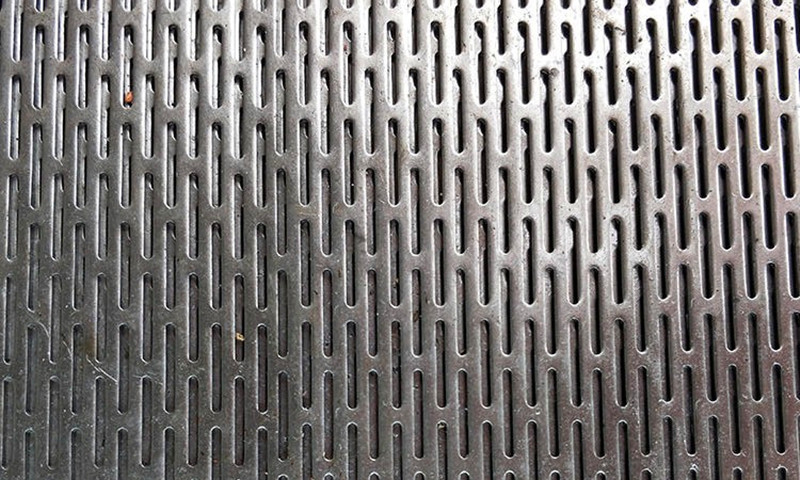

3. Hole Shape and Aperture Size

Hole design in steel perforated mesh can be round, square, slotted, or decorative. The complexity and precision required in punching different shapes affect manufacturing costs. Generally, the more intricate the hole pattern, the higher the cost.

4. Sheet Dimensions

Standard sizes include 1m×2m and 1.22m×2.44m. Custom sizes may incur additional cutting or processing charges, increasing the overall price.

steel perforated mesh

5. Surface Treatment

Surface finishing enhances durability and aesthetics of the perforated metal sheet. Common treatments include:

Spray Coating: Adds a protective layer and visual appeal.

Electroplating: Creates a metal finish that enhances corrosion resistance.

Hot-Dip Galvanizing: Immerses the steel in molten zinc, forming a thick anti-corrosive layer ideal for outdoor use.

Each treatment method comes with different cost implications depending on the protection level required.

6. Order Quantity

Larger orders typically receive better pricing. Bulk production reduces per-unit cost, and suppliers are more likely to offer discounts. Small or customized orders may carry higher prices.

7. Market Trends

Fluctuations in raw material prices, especially steel, directly impact perforated sheet pricing. Staying informed about market trends helps buyers optimize purchase timing.

steel perforated mesh

II. How to Get an Accurate Quote

To receive an accurate quote for steel perforated mesh, it's important to provide suppliers with detailed specifications:

Material Type – e.g., mild steel, stainless steel, or galvanized

Sheet Thickness – precise thickness required

Hole Shape & Size – round, square, slotted, etc.

Sheet Size – length and width

Surface Treatment – spray, galvanizing, electroplating, etc.

Quantity – bulk vs. small orders

Delivery Location – to calculate logistics costs

With this information, suppliers can provide fast and accurate pricing based on current market rates and production capabilities.

steel perforated mesh

III. Choosing the Right Supplier

When selecting a perforated metal sheet supplier, consider the following:

Certifications & Qualifications – Quality and manufacturing standards

Production Capability – Ability to meet your custom or bulk order needs

Lead Time – Delivery schedule and reliability

After-Sales Support – Responsiveness to technical or quality issues

A reliable supplier ensures long-term value and reduces project risks.

steel perforated mesh

IV. Conclusion

Steel perforated mesh is widely used in various industries. Its pricing is affected by several factors including material, thickness, hole type, and surface treatment. Understanding these variables helps buyers choose the right product at the best value. For inquiries or customized quotes, feel free to contact us. We are here to assist you with professional service and quality assurance.