What Is the Minimum Hole Size of Stainless Steel Perforated Sheet We Can Manufacture?

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-14 14:50:56 Browse:

Stainless steel perforated sheets are widely used across industrial manufacturing, architectural decoration, filtration, and other high-precision applications due to their corrosion resistance, durability, and clean appearance. One of the most frequently asked technical questions from customers is: What is the smallest hole size we can produce? This article provides a detailed explanation of that topic, covering technical feasibility, thickness-to-hole ratios, and practical advice for custom orders.

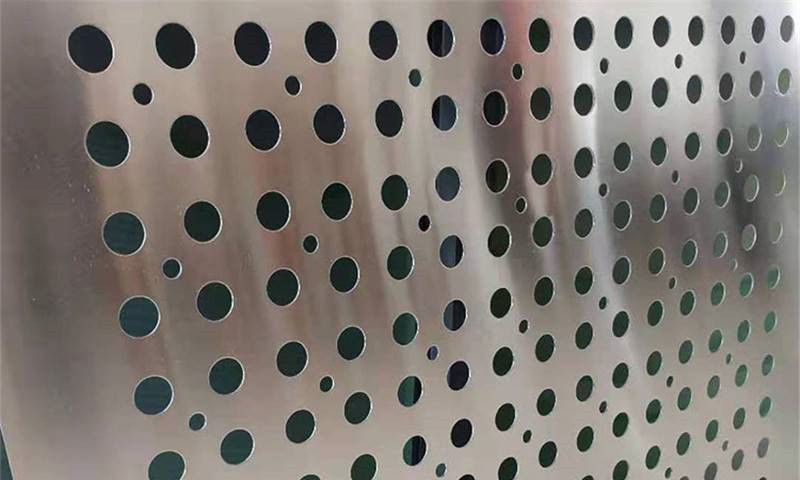

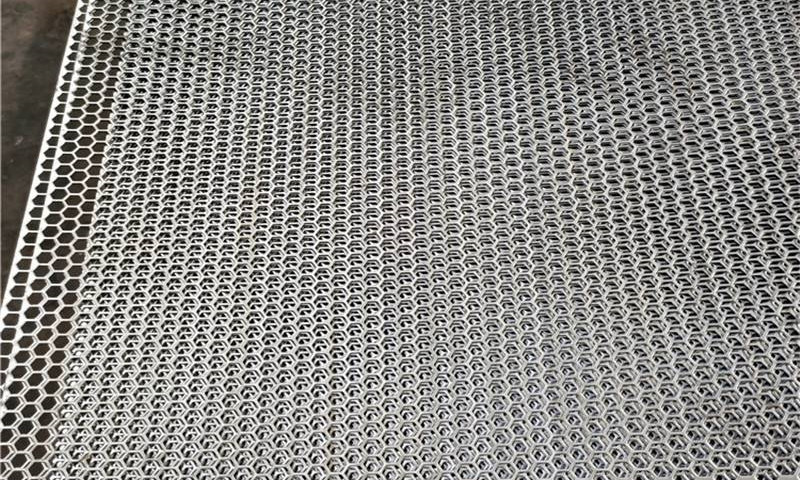

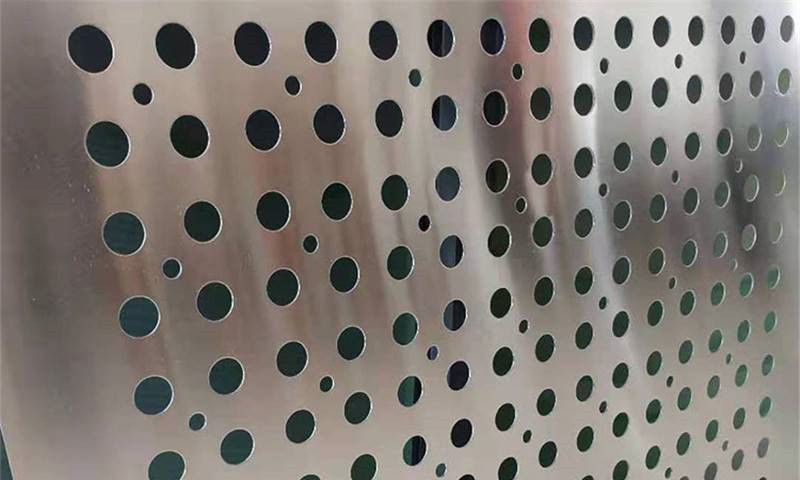

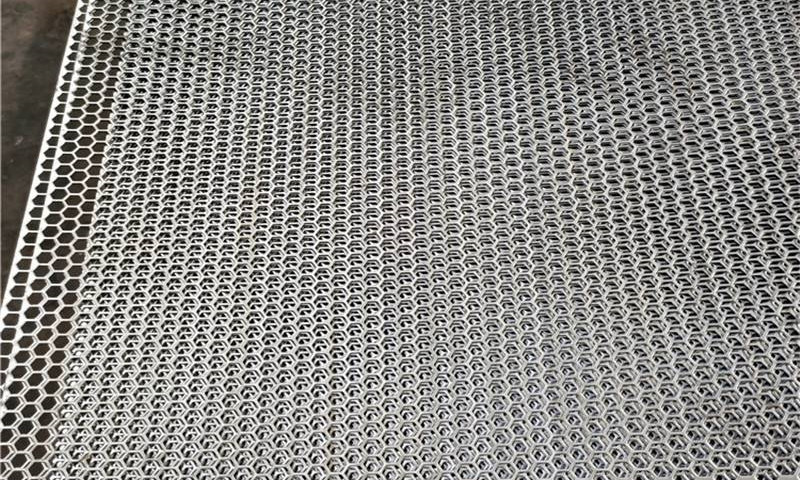

Stainless steel perforated sheet

What Is the Smallest Hole Size We Can Produce?

Under standard production conditions, the smallest hole diameter we can manufacture in a stainless steel perforated sheet is 0.2 millimeters. This level of precision is suitable for fine filtration, acoustic shielding, micro-ventilation, and high-end decorative purposes.

However, achieving such a small diameter is subject to certain material and equipment limitations—most notably the thickness of the stainless steel sheet used.

The Relationship Between Hole Diameter and Sheet Thickness

In perforation manufacturing, there is a commonly accepted guideline:

The hole diameter should not be smaller than the thickness of the sheet.

This means that if the intended hole size is 0.2mm, the thickness of the stainless steel sheet should not exceed 0.2mm. Exceeding this ratio can cause production problems such as tool breakage, material tearing, or irregular hole shapes.

Examples of suitable matches:

0.2mm hole → Sheet thickness should be 0.2mm or less

1.0mm thick sheet → Minimum recommended hole diameter: 1.0mm

3.0mm thick sheet → Hole diameter should be 3.0mm or more

This guideline is not absolute, but it is a helpful baseline for determining feasibility and managing costs in most industrial scenarios.

Stainless steel perforated sheet

Why Is It Not Recommended to Use Hole Sizes Smaller Than Sheet Thickness?

Reduced Precision: When the hole is smaller than the thickness, it's harder to apply consistent punching pressure, leading to burrs and deformation.

Shorter Tool Lifespan: Small-diameter holes with thick sheets increase stress on the tooling, leading to frequent wear and failure.

Lower Production Efficiency: Smaller holes in thick sheets require slower punching speeds and more frequent corrections.

Higher Production Costs: Complicated machining, increased material waste, and higher tool wear all contribute to greater overall costs.

Therefore, in real-world production, we evaluate the combination of hole size and sheet thickness to recommend the best configuration that balances quality, cost, and efficiency.

Our Capabilities and Advantages

As a professional manufacturer of stainless steel perforated sheets, we offer:

Precision punching machinery

Rich industry experience

Strict quality control processes

We are capable of delivering custom small-hole perforated sheets tailored to various applications such as fine filtration, micro-ventilation, decorative panels, and more.

If you have custom requirements, our technical team can work with your designs and provide optimized solutions that balance function, aesthetics, and cost-effectiveness.

Stainless steel perforated sheet

Conclusion

The smallest hole size we can produce on stainless steel perforated sheets is 0.2mm, but feasibility depends on matching the hole size to the material thickness. If you're planning to purchase or customize perforated sheets, we strongly recommend discussing your application and requirements with our team. We’re here to provide expert guidance and tailored solutions.

Feel free to contact us for more information on product specs, pricing, or samples.