Factors Influencing the Price of Stainless Steel Perforated Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-07 14:53:42 Browse:

Stainless steel perforated sheets are widely used in various industries due to their durability, aesthetic appeal, and versatility. However, their pricing can vary significantly based on multiple factors. Understanding these elements is crucial for making informed purchasing decisions.

1. Sheet Size

The dimensions of the sheet directly impact its price. Standard widths are typically 1.0m, 1.2m, or 1.5m. Custom sizes that deviate from these standards may result in material waste during production, leading to higher costs.

2. Sheet Thickness

Stainless steel perforated sheets are available in thicknesses ranging from 0.1mm to 20mm. Thicker sheets require more raw material and are generally more expensive due to increased material costs and processing challenges.

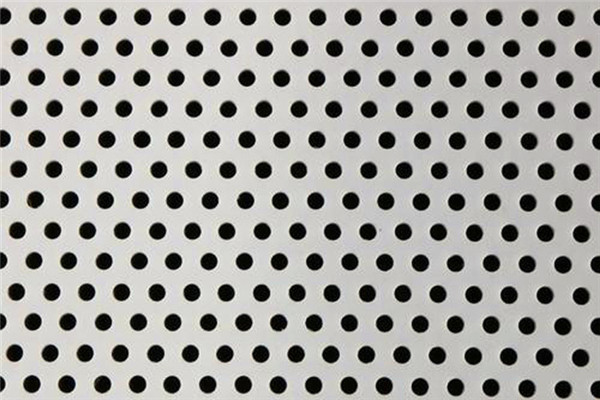

stainless steel perforated sheet

3. Material Grade

The type of stainless steel used significantly affects the price. Common grades include 201, 304, 316, 409, and 430. Each grade has different properties and costs:

201: Economical with moderate corrosion resistance.

304: Offers excellent corrosion resistance and is widely used.

316: Provides superior corrosion resistance, especially in marine environments, and is more expensive.

409 & 430: Used in specific applications; pricing varies based on composition and performance.

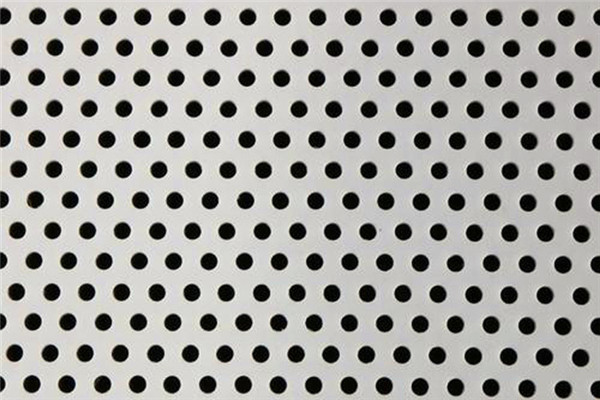

stainless steel perforated sheet

4.Hole Size The diameter of the holes in the sheet affects production speed and cost. Smaller holes (e.g., 0.2mm) are more challenging to produce and slow down manufacturing, increasing costs. Larger holes (up to 300mm) are easier to produce and generally cost less.

5.Hole Spacing (Pitch) The distance between holes influences the material's strength and the amount of material removed. Closer spacing results in more holes per unit area, increasing production time and cost. Wider spacing reduces the number of holes, lowering production time and cost. 6. Deep Processing Requirements Additional processing, such as bending, rolling, or polishing, adds to the overall cost. These processes require extra labor and equipment, increasing the final price of the product.