Versatile Advantages of Custom Stainless Steel Perforated Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-05-16 15:33:04 Browse:

With increasing demands for both functionality and aesthetics in architecture, industrial filtration, and municipal engineering, the stainless steel perforated sheet has become the preferred choice in metal sheet materials. Thanks to its durability, ventilation performance, and customizable patterns, this material stands out in various applications. Manufactured using high-precision CNC punching machines, stainless steel sheets can be processed in batches to form mesh-like structures that retain strength while offering excellent permeability, light transmission, and drainage.

Precision Perforation Process Ensures Quality

A stainless steel perforated sheet is produced through CNC-controlled punching combined with custom-designed molds. This technology enables accurate perforation on stainless steel sheets of varying thicknesses (typically from 0.5mm to 10mm). Each hole is positioned with precision, creating clean edges without burrs or deformation. This smooth finish supports subsequent surface treatments such as sandblasting, electroplating, or wire drawing, enhancing both appearance and performance.

Diverse Hole Patterns to Meet Various Needs

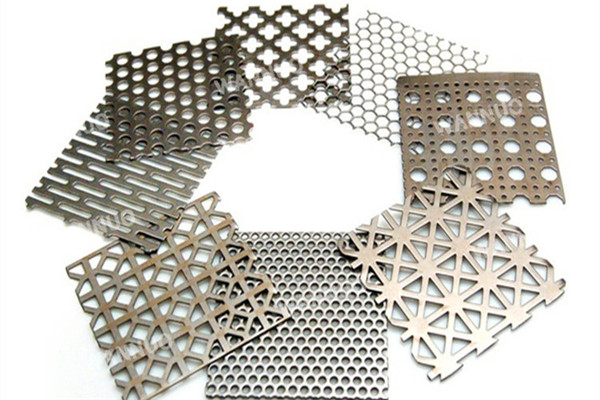

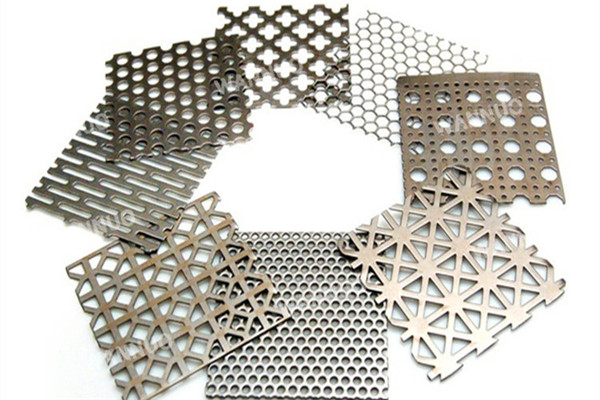

Unlike traditional mesh panels, the key advantage of the stainless steel perforated sheet lies in its wide variety of hole shapes. According to design requirements, the sheet can be customized with patterns including round, oval, oblong, square, rectangular, triangular, hexagonal, cross-shaped, diamond, and fish-scale holes. Artistic options such as petal, star, flower, or reinforced bridge shapes are also available, enabling eye-catching designs for architectural facades, ceilings, or interior partitions.

Stainless steel perforated sheet

Flexible Customization for Project Precision

Each project may require different hole sizes, spacing, and sheet thicknesses. The stainless steel perforated sheet supports full customization based on technical drawings or samples. Hole diameters can range from a few millimeters to over ten millimeters, with adjustable spacing to meet requirements for high or low open area ratios. Sheet dimensions can also be custom-cut for seamless installation and quick assembly at job sites.

Widespread Applications Showcasing Quality

Thanks to its robust, corrosion-resistant, and easy-to-clean nature, the stainless steel perforated sheet is widely used in decorative screens, building facades, ceiling panels, interior dividers, sunshades, acoustic panels, filter cores, drainage systems, manhole covers, and ship decks. Whether it’s for a modern minimalist partition or an industrial-style equipment guard, the right hole pattern and surface finish can enhance both form and function.

Conclusion

Choosing a stainless steel perforated sheet means benefiting from the reliability and weather resistance of metal while enjoying the freedom of customizable patterns and functional performance. From commercial decor to industrial filtration, stainless steel perforated sheets offer an aesthetic and high-performing solution. Contact us today to explore our product specifications and case studies—and elevate your project with both quality and style.