Why Stainless Steel Perforated Sheets May Rust and How to Prevent It

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-07 18:20:56 Browse:

Stainless steel perforated sheets are widely used in architectural decoration, machinery manufacturing, filtration equipment, and many other fields due to their excellent corrosion resistance, attractive appearance, and good ventilation properties. However, there is a common misconception that "stainless steel" means "never rusts." In reality, this is a misunderstanding of the material's properties.

1. Corrosion Resistance Mechanism of Stainless Steel

The strong corrosion resistance of stainless steel perforated sheets comes from a thin, stable chromium oxide film on their surface. This passive layer effectively prevents oxygen and moisture from coming into direct contact with the metal substrate, thus resisting corrosion.

However, this film is not invincible. When exposed to certain environments—such as high humidity, salt-rich air, or chemically aggressive conditions—the passive layer can be damaged, leading to localized corrosion or rust.

2. Common Corrosive Factors

Chloride Ion Attack: Chloride ions (Cl⁻), commonly found in seawater, salt, and even sweat, can penetrate and destroy the passive layer, resulting in pitting or crevice corrosion.

Acidic or Alkaline Environments: Strong acids or bases accelerate corrosion, especially in industrial areas affected by acid rain or chemical emissions.

Mechanical Damage: Scratches or impact damage may compromise the protective layer, exposing the underlying metal to corrosion.

Contaminant Buildup: Dust, grease, and debris can retain moisture and corrosive substances, creating micro-environments that promote rust.

Galvanic Corrosion: Contact with dissimilar metals may trigger electrochemical reactions, especially in moist environments.

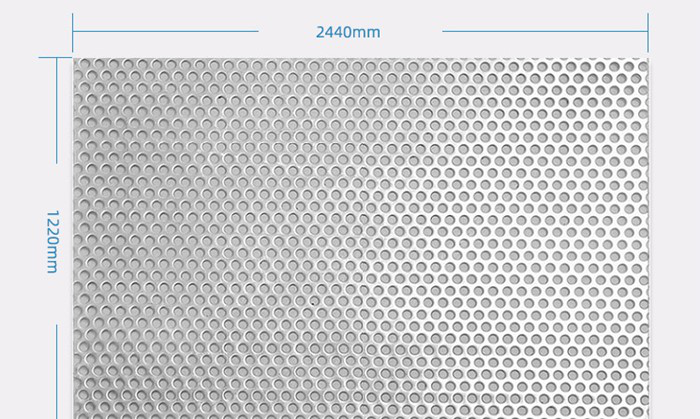

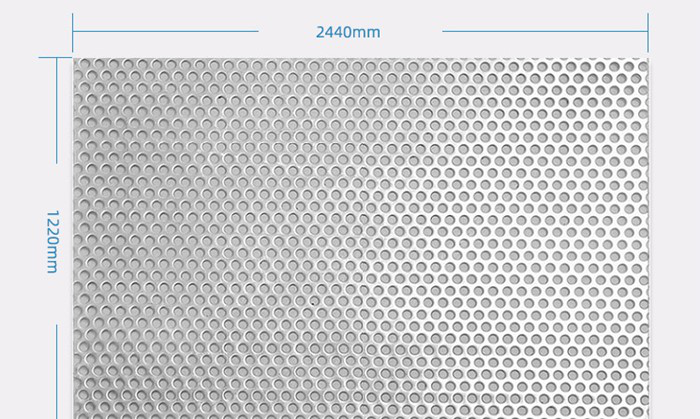

Stainless steel perforated sheet

How to Prevent Rust on Stainless Steel Perforated Sheets

1. Select the Right Material

Choose stainless steel grades suitable for the intended environment. For example, in coastal or marine applications, 316 stainless steel offers better resistance to chloride corrosion than 304 stainless steel, which is adequate for indoor or mild outdoor settings.

2. Enhance Surface Treatments

Polishing: Improves surface smoothness, reducing contaminant adhesion.

Passivation: Strengthens the stability of the passive film, enhancing corrosion resistance.

Protective Coatings: In highly aggressive environments, applying anti-corrosion coatings can offer additional protection.

3. Regular Cleaning and Maintenance

Clean the surface regularly to remove dust, oil, or corrosive substances. Keeping the stainless steel perforated sheet dry and clean will significantly extend its service life.

4. Avoid Exposure to Corrosive Substances

Minimize contact with strong acids, alkalis, or chloride-containing chemicals during use to reduce the risk of corrosion.

Conclusion

While stainless steel perforated sheets offer excellent corrosion resistance, they are not immune to rust under certain conditions. Understanding the causes of corrosion and applying proper preventive measures—such as material selection, surface treatment, and routine maintenance—can help maximize performance and longevity.

At Hebei Senchi Wire Mesh Products Co., Ltd., we specialize in the production and development of stainless steel perforated sheets. We offer a variety of specifications and materials to meet diverse customer needs. For more information, please visit our website or contact our customer service team.