How to Quickly Identify Stainless Steel Perforated Sheet Material: A Practical Guide

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-07 15:26:14 Browse:

1. Introduction and Overview of Materials

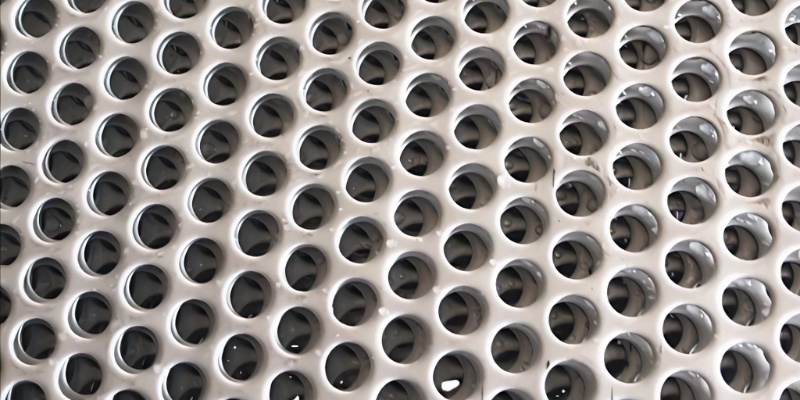

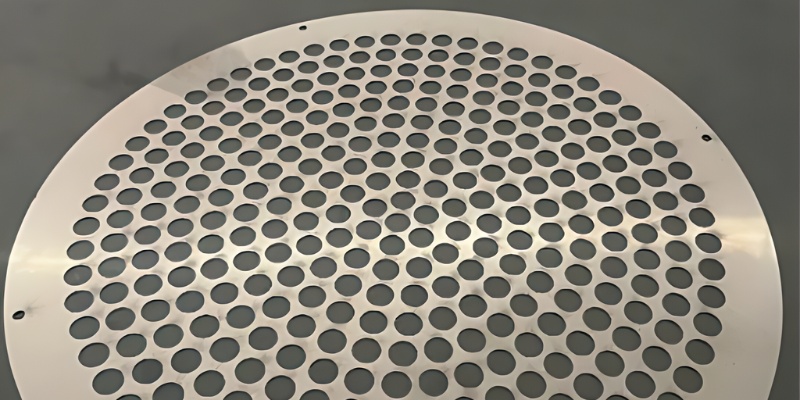

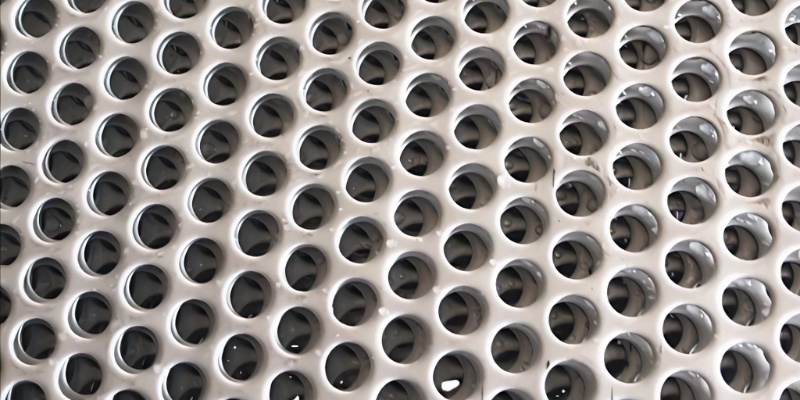

Stainless steel perforated sheet is a widely used metal product across architecture, industrial equipment, safety enclosures, and decorative applications. These sheets are created by punching various hole patterns into stainless steel using CNC perforation machines. Common stainless steel grades include 201, 304, 316, 409, and 430, each offering different advantages in corrosion resistance, strength, and price.

2. Why Material Identification Matters

Accurate material identification of stainless steel perforated sheets is critical to ensuring quality and safety. Some unethical suppliers may substitute inferior materials for premium ones, leading to structural risks and financial loss. For end-users and buyers, the ability to identify material grades helps make confident purchasing decisions and avoid counterfeit stainless steel sheets.

3. Fast Identification Methods Explained

A highly efficient way to identify stainless steel perforated sheet materials is to use a dedicated stainless steel testing reagent. Here’s how:

Even Application: Apply the reagent evenly to the surface of the stainless steel perforated sheet.

Color Observation: Observe any color changes within three minutes.

Initial Judgment: Use the reaction time and resulting color as a reference to determine the likely grade of stainless steel.

This method is quick, simple, and ideal for on-site inspections.

4. Reaction Characteristics of Common Stainless Steel Grades

When using stainless steel identification reagents, each material grade displays unique reaction patterns:

Grade 201:

Turns red within 10 seconds if manganese content is high (low quality); turns red within 50 seconds for standard-compliant grade (better quality).

Grade 202:

Turns red within 1 minute; has properties between 201 and 304.

Grade 301:

Turns red within 2 to 3 minutes, usually with a light color that requires close observation.

Grade 304:

Shows little to no color change within 3 minutes, indicating superior corrosion resistance and stable quality.

For other grades like 316, 409, and 430, professional testing equipment or manufacturer verification is recommended for accurate material identification.

5. How to Avoid Counterfeit Stainless Steel Products

To ensure you're purchasing genuine stainless steel perforated sheets:

Choose Trusted Manufacturers: Always buy from reputable suppliers with strong track records.

Request Testing Certificates: Ask for official test reports and material certifications.

Conduct On-Site Testing: Use rapid testing reagents for preliminary on-the-spot verification.

Increase Knowledge: Familiarize yourself with the characteristics of various stainless steel grades to avoid being misled.

6. Conclusion

Understanding how to quickly identify stainless steel perforated sheet materials helps you ensure quality and avoid substandard products. Our team is dedicated to providing high-performance perforated metal products and technical support. For questions about stainless steel material identification or product consultation, feel free to contact our experts for reliable assistance.