Comprehensive Guide to 304 Perforated Sheet: Material, Hole Types, and Applications

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-11 16:11:00 Browse:

What is 304 Perforated Sheet?

304 perforated sheet is a type of metal sheet made from high-quality 304 stainless steel, processed through CNC punching machines to create custom-designed holes based on client requirements. The resulting sheet combines structural strength, aesthetic appeal, and functional versatility, making it a popular choice across a wide range of industries such as filtration, ventilation, safety protection, and architectural decoration.

Alternative names include:

304 perforated metal

Stainless steel punched sheet

Material Introduction: Why Choose 304 Stainless Steel?

304 stainless steel is a widely used austenitic stainless steel grade known for its excellent corrosion resistance, high temperature tolerance, and ease of fabrication. With its balanced composition of chromium and nickel, 304 stainless steel is ideal for punching and shaping into durable and attractive perforated sheets.

Main advantages of 304 stainless steel:

Excellent resistance to corrosion from acids, alkalis, and salts

High thermal resistance

Suitable for outdoor and humid environments

Smooth surface with high aesthetic value

Easy to punch, weld, and form

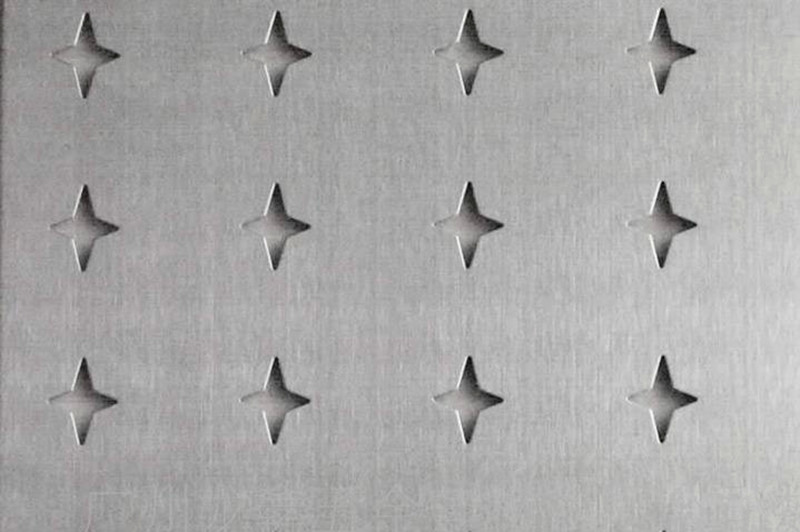

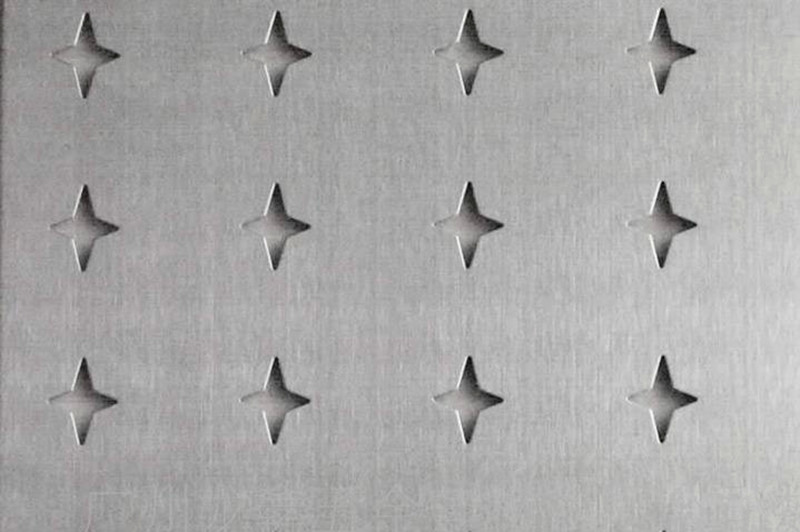

304 perforated sheet

Variety of Hole Types

304 perforated sheet is available in a wide selection of hole shapes and patterns. Customized layouts—such as straight rows, staggered rows, and circular formations—are designed to meet both functional and decorative requirements.

Common hole types include:

Round holes (ideal for ventilation and filtration)

Slotted holes (good for drainage and airflow)

Square holes (suitable for sieving and decoration)

Triangle holes

Hexagonal holes (honeycomb structure for strength)

Fish scale holes, bridge holes, star holes

Cross holes, nail-shaped holes, pentagon holes

Human-shaped holes, “井” (grid) shaped holes, and other custom patterns

Technical Specifications & Customization

To suit different applications, 304 perforated sheets can be tailored in terms of thickness, hole diameter, and overall size.

Thickness: Customizable from 0.1mm to 20mm

Hole diameter: Precisely made to order

Sheet dimensions: Full sheets or cut-to-size available

Open area: Adjustable to balance airflow and strength

304 perforated sheet

Key Performance Features of 304 Perforated Sheets

304 stainless steel perforated sheets not only offer visual appeal but also deliver outstanding functionality. Their wide range of uses is supported by several key material and structural advantages.

1. High Sand Resistance and Filtration Performance

Multi-layered configurations offer excellent sand-blocking capabilities, ideal for oil and gas wells where sand control is critical.

2. Uniform Hole Distribution and Anti-Clogging

CNC precision punching ensures even hole spacing, enhancing permeability and reducing the risk of blockages.

3. Large Filtration Area, Low Resistance

High open-area percentage ensures large flow capacity with minimal resistance—ideal for filtration and heat dissipation systems.

4. Superior Corrosion Resistance

The inherent properties of 304 stainless steel ensure long-term stability in harsh environments, including exposure to acids, alkalis, and saline media.

5. Structural Stability and Deformation Resistance

Multi-layer welding or composite punching processes reinforce structural integrity, making the sheets resistant to warping or pressure damage.

Broad Range of Applications

Thanks to their performance versatility and customizable design, 304 perforated sheets are used across a wide spectrum of industries and projects.

Common applications include:

Architectural Design: Wall cladding, ceilings, stair railings, facades

Industrial Filtration: Air and liquid filtration systems

Oil & Gas Industry: Sand control screens and filters

Agricultural Equipment: Grain sieving, aeration systems

Environmental Engineering: Wastewater treatment, dust collection units

Transportation Infrastructure: Subway ventilation covers, highway noise barriers

Home Appliances: Speaker grilles, cabinet vents

Conclusion: Why Choose 304 Perforated Sheet?

Choosing 304 perforated sheet means selecting a material that combines quality, durability, and flexibility. Whether your application is focused on structural integrity, visual presentation, or filtration performance, 304 stainless steel perforated sheets provide a reliable solution.

If you are looking for custom specifications, sample inquiries, or detailed consultation, feel free to contact us. We are committed to providing high-quality perforated metal products tailored to your specific needs.