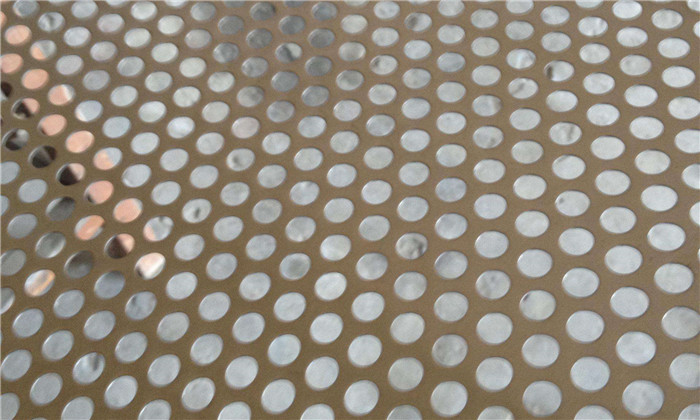

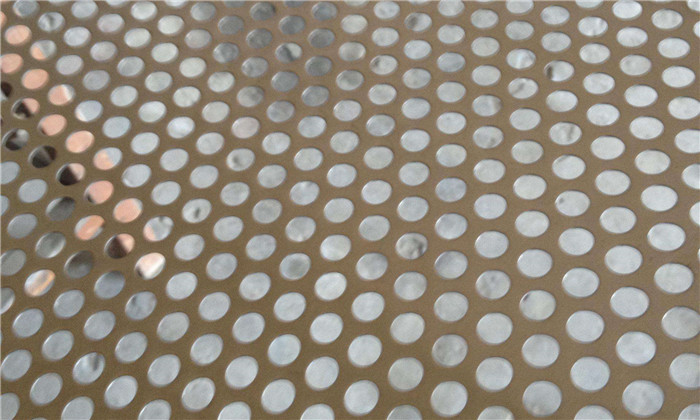

High Precision Manufacturing Process of Stainless Steel Perforated Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-07 18:10:30 Browse:

In modern industrial manufacturing, stainless steel perforated sheets are widely used in architectural decoration, mechanical equipment, and ventilation systems due to their excellent corrosion resistance, strength, and visual appeal. To ensure the quality and accuracy of each sheet, Hebei Senchi implements strict quality control measures throughout the production process, focusing on meticulous detail management.

1. Daily Maintenance of CNC Punching Machines

CNC punching machines are the core equipment in the production of stainless steel perforated sheets. Their operational condition directly affects product quality. Before daily production begins, operators perform thorough lubrication and maintenance to ensure smooth operation of all moving parts. Special attention is given to critical components such as the punch head, lead screw, and feeder. Any issues such as looseness or misalignment are promptly adjusted or replaced to maintain precision.

2. Strict Control of Raw Material Positioning

When stainless steel sheets are mounted onto the feeding mechanism, operators repeatedly verify the positioning for accuracy. The pressure and clamping force of the fixtures are adjusted as needed to ensure the sheet remains stable during punching, preventing any material shift and ensuring exact hole placement.

Stainless steel Perforated sheet

3. Regular Inspection and Maintenance of Molds

Mold precision has a direct impact on hole size and shape. Each time a mold is replaced, it is sent to a specialized inspection department for comprehensive checking to ensure that apertures and clearances meet technical standards. Regular repairs and fine-tuning of molds are essential to maintain consistency in hole shape and size.

4. Punch Tool Grinding and Replacement

To keep the punch tools sharp and dimensionally accurate, CNC grinders are used for precise sharpening. Hebei Senchi follows a regular punch replacement schedule to avoid defects caused by tool wear or dulling, ensuring smooth surfaces and accurate positioning of holes in every perforated sheet.

5. Production Philosophy: Quality First

Through this series of refined management and control measures, Hebei Senchi consistently produces stainless steel perforated sheets with accurate hole positioning and a smooth finish. The company adheres to a "quality first" manufacturing philosophy, committed to providing high-performance, top-quality products and services. We look forward to collaborating with more customers for mutual growth.