5. Challenges with Special Specifications

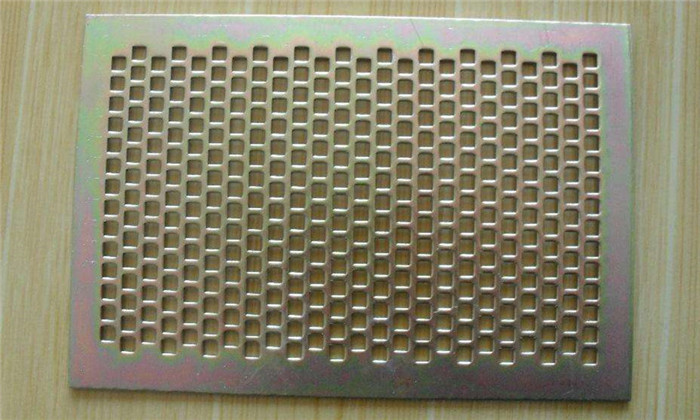

Certain special specifications of stainless steel perforated sheets, such as those with larger hole diameters, thicker plates, or smaller hole spacing, tend to experience more stretching during the punching process. This additional stretching increases the likelihood of the sheet deforming, making it more challenging to maintain a flat surface. The thicker the plate or the closer the hole spacing, the more difficult it becomes to achieve a flat final product. In these cases, extra care must be taken during production to minimize deformation and improve the overall quality of the sheet.

Conclusion

The uneven surface of stainless steel perforated sheets is generally the result of multiple factors working together, including punch wear, mold clearance issues, small hole spacing, and poor material quality. To prevent these problems, it is essential to implement effective quality control measures, such as regularly checking and replacing punches, accurately adjusting mold clearance, using high-quality materials, and optimizing hole spacing design. By improving production processes and quality control, manufacturers can achieve a higher level of precision in their perforated sheets, ensuring they meet customer demands.

We hope this article helps you better understand the factors that affect the flatness of stainless steel perforated sheets and provides useful insights for improving production quality.