How to Determine If a Stainless Steel Perforated Sheet Is Qualified

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-05-26 14:58:29 Browse:

Stainless steel perforated sheet is widely used in architectural decoration, industrial manufacturing, filtration, and screening due to its diverse hole designs and excellent performance. To ensure optimal functionality and quality in actual applications, the qualification of a stainless steel perforated sheet must be evaluated based on the following key criteria:

1. Dimensional Accuracy

Due to mechanical errors during the punching process, the dimensional tolerance of a stainless steel perforated sheet should be controlled within ±2mm. This range meets the basic precision requirements of most engineering projects.

2. Sheet Thickness

The thickness of the sheet directly affects its load-bearing capacity and service life. Typically, the thickness tolerance should not exceed ±0.1mm, and the actual thickness must not fall below the minimum specified by the customer to guarantee stability and safety in use.

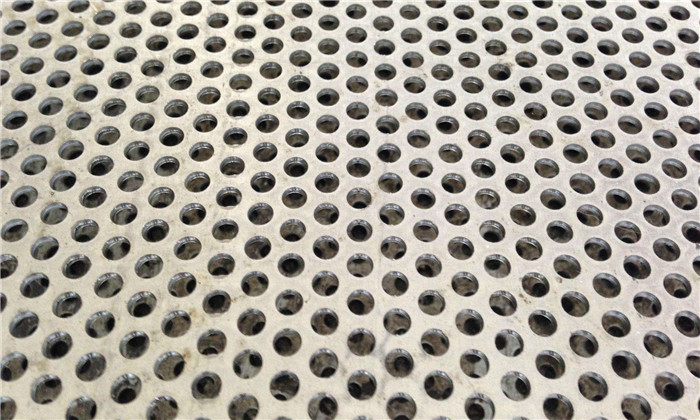

stainless steel Perforated sheet

3. Hole Diameter Precision

Uniformity of hole diameter is essential for functions like filtration and ventilation. Generally, the tolerance for hole diameter should be within ±0.05mm to ensure both functionality and visual appeal.

4. Hole Spacing Consistency

The distance between holes must be consistent, with a tolerance no greater than ±0.1mm. Consistent spacing not only impacts the aesthetic quality but also the overall performance of the stainless steel perforated sheet in practical applications.

5. Diagonal Deviation

The difference between the diagonals of the sheet should be controlled within ±5mm. Excessive deviation can lead to installation difficulties or compromise structural stability.

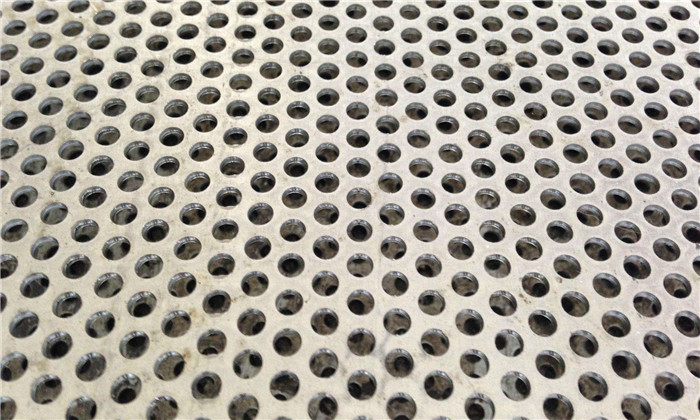

Stainless steel perforated sheet production workshop

6. Surface Flatness

Unless otherwise specified by design, the surface of the perforated sheet should remain flat without noticeable warping or deformation. A flat surface facilitates subsequent processing and installation, improving the overall quality of the product.

In summary, determining whether a stainless steel perforated sheet is qualified involves a comprehensive assessment of its dimensions, thickness, hole diameter, spacing, diagonal accuracy, and surface flatness. Only sheets that meet all these criteria can perform effectively and reliably in real-world applications.