Applications by Hole Shape

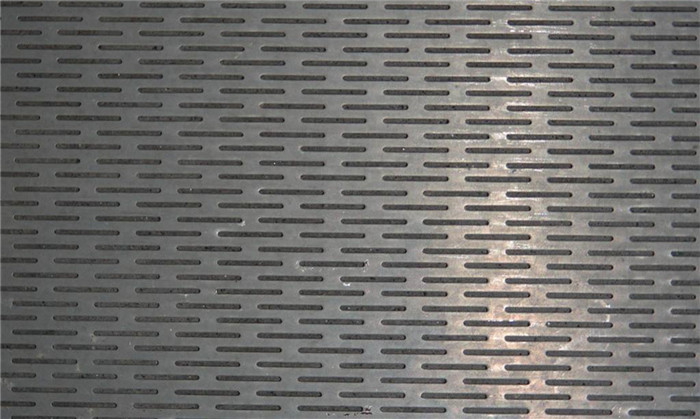

1. Screening and Filtration

Recommended Hole Types: Round holes, slotted holes

Use Case: Industries such as mining, chemical processing, grain production, and water treatment benefit from using perforated plates for material screening or liquid/air filtration. Round holes ensure balanced flow and efficiency, while slotted holes are ideal for larger volumes or directional filtration.

2. Architectural and Interior Decoration

Recommended Hole Types: Round, square, triangle, cross, pentagram, plum blossom, louvered, etc.

Use Case: In architectural facades, ceilings, partitions, and decorative panels, diverse hole patterns help designers create visual interest and thematic consistency. For example, pentagram holes suit modern interiors, while plum blossom holes are often used in traditional or Asian-style architecture. Honeycomb and diamond holes are commonly selected for curtain walls or large-format screens.

3. Ventilation and Heat Dissipation

Recommended Hole Types: Louvered, round, slotted, hexagonal

Use Case: Equipment housings, air conditioning covers, electronic devices, and control cabinets require effective airflow and heat dissipation. Louvered holes provide directional ventilation, while round and hexagonal holes allow for uniform cooling without compromising structural integrity.

4. Anti-Slip Safety Applications

Recommended Hole Types: Convex round holes, crocodile jaw holes

Use Case: Industrial stairs, walking platforms, manufacturing areas, and wet zones demand slip-resistant surfaces. Perforated plates with raised or sharp-edged patterns like convex holes or crocodile jaw holes improve traction and safety under heavy or slippery conditions.