2. Wide Range of Thickness and Hole Diameters

Stainless steel perforated sheets are available in a broad range of thicknesses, from as thin as 0.1mm to as thick as 20mm. The hole diameter options range from 0.2mm up to 300mm, offering solutions for both ultra-fine filtration and large-scale ventilation or structural applications. Whether you need a precision micro-perforated screen or a heavy-duty protective panel, the specifications can be customized accordingly.

3. Variety of Stainless Steel Materials

To suit different environments and performance needs, stainless steel perforated sheets can be manufactured using various grades of stainless steel:

200 Series (e.g., 201, 202) – Cost-effective, suitable for general applications

300 Series (e.g., 304, 316, 316L) – Excellent corrosion resistance, ideal for harsh environments

400 Series (e.g., 410, 430) – Higher hardness, suitable for structural support

Material selection depends on the intended application—whether it’s indoors, outdoors, in chemical environments, or in coastal areas with high humidity.

4. Flexible Processing and Finishing Options

Stainless steel perforated sheets are not only customizable in design but also adaptable in processing. After punching, the sheets can undergo secondary processes including:

Bending

Rolling or curving

Laser cutting

Shearing to size

Electrolytic polishing

These processes are usually completed in the production facility, enabling the end user to receive ready-to-use products without the need for additional fabrication.

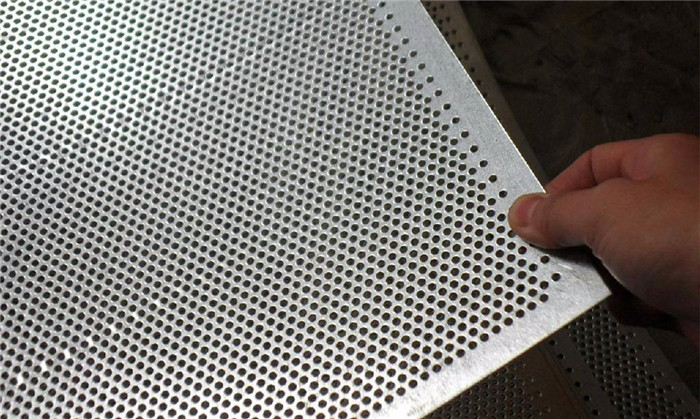

5. Product Features and Advantages

Compared to regular metal sheets, stainless steel perforated sheets offer a range of technical and visual advantages:

Flat surface – Smooth finish without burrs

Accurate hole spacing – High precision ensures uniformity

Corrosion resistance – Especially in 304 and 316 grades

Structural strength – Lightweight yet strong

Ventilation and permeability – Ideal for airflow and sound absorption

These characteristics make stainless steel perforated sheet a premium material for both protective and aesthetic purposes.

6. Wide Range of Applications

Thanks to its durability, customizable design, and visual appeal, stainless steel perforated sheet is widely used in various industries, including:

Architectural decoration – Facade panels, ceilings, stair railings, privacy screens

Industrial manufacturing – Machine guards, filtration systems, sound insulation panels

Infrastructure and transport – Subway barriers, highway sound barriers

Environmental and agricultural sectors – Grain storage ventilation, water treatment screens

Home and commercial use – Speaker covers, kitchen equipment panels, furniture design

7. Conclusion

The stainless steel perforated sheet is a highly versatile and durable solution for both industrial and architectural needs. With customizable hole patterns, material grades, and processing options, it meets diverse requirements across applications. Whether for ventilation, decoration, filtration, or mechanical protection, this material combines performance and style in one smart solution.

If you're looking for a high-performance material that offers both functionality and design flexibility, stainless steel perforated sheet is an ideal choice worth considering.