How to Solve the Deformation Problem of Stainless Steel Perforated Sheet During Production

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-14 14:07:36 Browse:

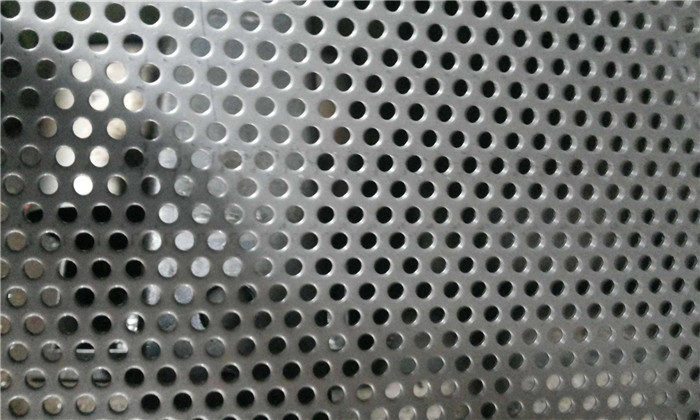

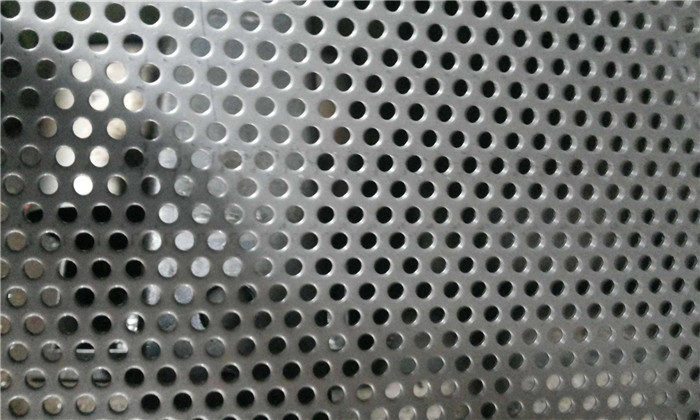

In the manufacturing process of stainless steel perforated sheet, one common issue often encountered is deformation. After punching, the sheet may become curved or warped, appearing bow-shaped or uneven. This deformation not only affects the appearance but also impacts subsequent installation and usage. So, what causes this problem, and how can we effectively solve it?

1. The Root Cause of Deformation

The deformation of stainless steel perforated sheet mainly results from uneven internal stress during the punching process. As the die repeatedly punches holes into the metal sheet, localized tension and compression occur. When punching is applied over a large area or on thin sheets, this stress accumulates and leads to warping or bending. It’s a mechanical consequence of high-frequency stamping that’s especially evident in thin or densely perforated sheets.

2. Post-Processing: Using a Straightening Machine

To correct the deformation of stainless steel perforated sheet after production, a professional straightening machine can be used. These machines apply continuous pressure through a set of rollers to flatten the sheet and release built-up internal stress. After straightening, the flatness of the product is significantly improved, making it more suitable for transportation, installation, and downstream processing.

3. Preventive Measures: Optimize the Production Process

Instead of relying solely on post-processing, it is also beneficial to optimize production methods to reduce the chances of deformation from the start.

3.1 Regularly Check Punch Wear

The punch tool is essential in perforation, and over time it will wear out. A worn punch can cause inconsistent punching, leading to increased material stress and higher chances of deformation. A routine inspection and timely replacement of worn punches can maintain the precision and stability of the process.

3.2 Design Proper Die Clearance

The clearance between the upper and lower die significantly impacts the quality of the punch and the amount of deformation. Too small a gap may cause excessive resistance, while too large a gap can result in burrs and distortion. During die design, CAD software or other engineering tools should be used to simulate and fine-tune the die clearance to ensure it suits the specific sheet thickness and material type.

3.3 Optimize Punching Sequence and Layout

The punching pattern and sequence can influence how stress accumulates across the sheet. For example, using an alternating or staggered punching sequence can reduce localized stress concentration. Avoiding excessive punching in a single area helps distribute the force more evenly, which in turn minimizes warping.

Stainless steel Perforated sheet

4. Choose the Right Material and Thickness

The thickness and type of stainless steel used also affect the likelihood of deformation. Thicker sheets are generally more resistant to bending, while some stainless steel grades, like austenitic types, are more ductile and prone to stress-induced deformation. Choosing the appropriate sheet based on your project requirements can make a significant difference.

5. Conclusion

Deformation in stainless steel perforated sheets is a common but manageable issue. By applying a combination of proper post-processing methods like straightening and optimizing the production process—including punch maintenance, die clearance design, and punching strategy—it’s possible to greatly reduce deformation. Additionally, selecting the right material further ensures product quality. As a professional manufacturer, we are committed to delivering high-quality, flat stainless steel perforated sheets tailored to meet the needs of various industrial and architectural applications.