What are the production steps of stainless steel punching net

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-14 14:13:31 Browse:

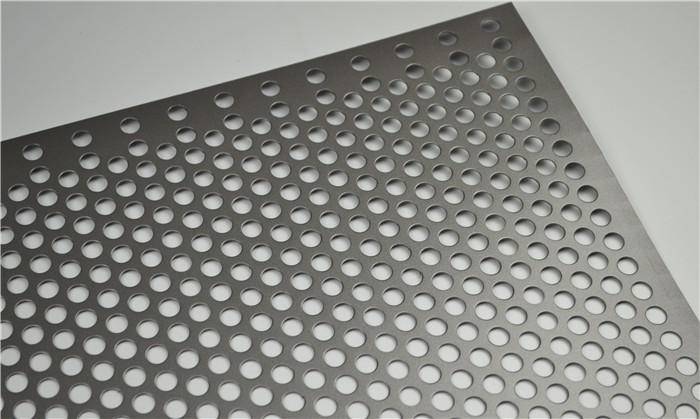

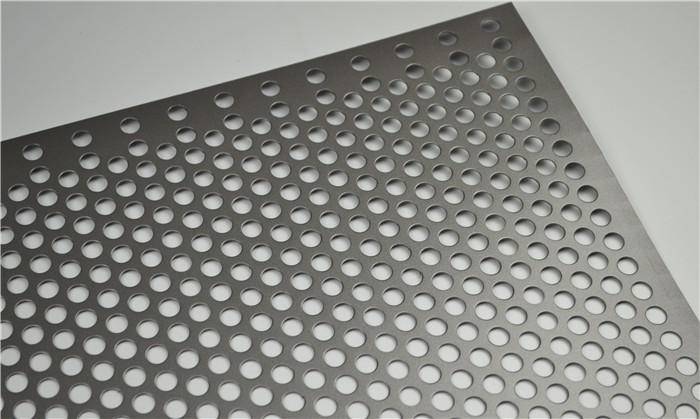

Stainless steel punching net is widely used in building decoration, filtration systems, protective barriers, ventilation panels, and many other industrial and commercial applications. Thanks to its excellent corrosion resistance, aesthetic appeal, and structural strength, it has become an essential material in various fields. But how is a high-quality stainless steel punching net produced? Below is a detailed explanation of each step in the production process.

1. Confirming Product Specifications – The Crucial First Step

Before starting the production of a stainless steel punching net, detailed communication with the customer is essential. Understanding the exact requirements ensures the final product meets application standards and guides mold selection and process planning. Parameters to confirm include:

Hole shape (e.g., round, square, slotted)

Hole diameter

Hole pitch (distance between holes)

Mesh layout (straight row, staggered, etc.)

Sheet thickness

Material type (commonly 304 or 316 stainless steel)

Sheet size (length and width)

Surface treatment (brushed, electro-polished, sandblasted, etc.)

Whether deep processing is required (bending, welding, cutting, rolling, etc.)

Only with a complete and accurate understanding of these specifications can a proper production plan be developed.

2. Mold Preparation – Foundation for Precision

After confirming all technical parameters, the next step is checking the mold inventory. It is important to see whether existing molds can meet the design requirements. If suitable molds are not available, custom molds must be manufactured. High-precision molds are crucial to ensure the hole accuracy, uniformity, and flatness of the final stainless steel punching net.

3. Material Procurement – Quality Starts with the Right Material

Once molds are ready, the required stainless steel sheets are ordered from reliable suppliers. The selected sheets must meet the required standards for thickness, surface condition, and material grade. High-quality raw materials are the foundation of a durable and accurate stainless steel punching net.

4. Machine Setup and Mold Installation – Ensure Stable Operation

The prepared mold is mounted onto a CNC punching machine. Technicians perform careful adjustments and calibration to ensure the machine operates accurately and efficiently throughout the production process.

stainless steel punching net

5. CNC Programming – Precision via Automation

Operators program the CNC punching machine based on the customer’s specifications. This includes setting hole spacing, layout patterns, punching sequence, and cutting paths. CNC programming allows for consistent, automated operation that improves efficiency and minimizes waste.

6. Punching Process – The Core Stage of Production

With all systems ready, the production process begins. The CNC punching machine processes the stainless steel sheet according to the programmed settings. During this stage, operators monitor the machine to ensure hole quality, positioning accuracy, and smooth operation.

7. Post-Processing and Packaging – Details Make the Difference

After punching is completed, additional finishing processes are applied based on the customer’s needs:

If needed, surface polishing removes burrs and enhances appearance.

For more complex applications, deep processing is performed (cutting, bending, welding, etc.).

Finally, cleaning and packaging are conducted to protect the product during transport and ensure it is installation-ready.

Conclusion

The production of stainless steel punching net is a systematic process that requires precision, coordination, and attention to detail at every stage. From confirming product parameters and preparing molds to material selection, programming, punching, and finishing, each step plays a critical role in delivering a high-quality product.

At our company, we adhere to the principles of quality-driven manufacturing and customer-first service. We are committed to providing durable, accurate, and beautifully finished stainless steel punching nets tailored to your specifications. Feel free to contact us for custom solutions and competitive quotes.