Thick stainless steel perforated sheets are widely used in industries such as chemical processing, mining, and food manufacturing due to their excellent durability and diverse application capabilities. This article offers a comprehensive buying guide covering features, key specifications, hole shapes, material selection, and real-world usage scenarios of Stainless Steel Perforated Sheet products.

Product Features

Exceptional Durability:

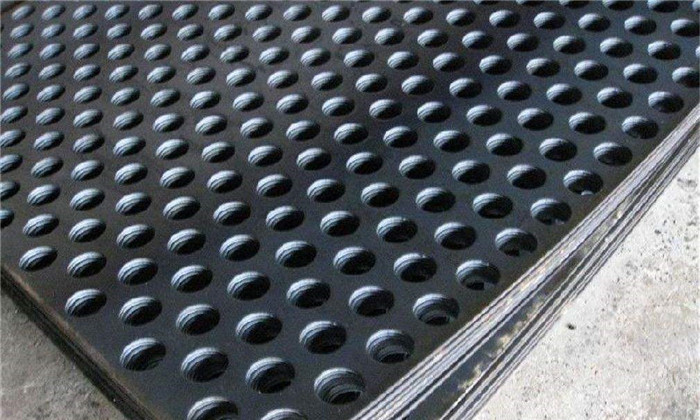

Made with stainless steel plates ranging from 3mm to 20mm in thickness, these perforated sheets are manufactured using precision punching techniques, providing a lifespan three to five times longer than standard mesh products.

Outstanding Environmental Resistance:

Designed to withstand temperature ranges from -50°C to 800°C and pH values between 1 and 14, making them suitable for extreme operational environments.

Flexible Customization:

Non-standard sizes are fully supported, with a maximum manufacturing size of up to 3m x 6m, meeting various industrial needs.

Key Specifications

Plate Thickness Options

3–6mm:

Ideal for lightweight applications such as food-grade filtration and architectural decoration, with a load-bearing capacity of 1200–2500 kg/m².

8–12mm:

Suitable for medium-duty tasks like ore screening, with impact resistance up to 6000 kg/m².

14–20mm:

Best for heavy-load conditions such as oil-gas separation and chemical reactors, with a maximum load capacity of 12,000 kg/m².

Hole Shape Options

Round Holes (Ø 3–50mm):

Cost-effective with customizable open area ratios ranging from 25% to 70%.

Slotted Holes (Ratio 2:1 to 5:1):

Ideal for filtering fibrous materials, offering excellent anti-clogging performance.

Hexagonal Holes:

Honeycomb layout improves structural strength by up to 30%, commonly used in vibrating screen panels.

Diamond Holes (10–60mm across diagonals):

Perfect for architectural façades, combining ventilation with aesthetics.