What Is the Aperture and Hole Pitch of Stainless Steel Perforated Sheet?

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-11 16:31:26 Browse:

When purchasing or customizing stainless steel perforated sheets, many users encounter a common question: What exactly do "aperture" and "hole pitch" mean? These two parameters play a crucial role in determining the product’s performance, appearance, and practical use. In this article, Anping County Senchi Perforated Screen Factory provides a detailed explanation of the definitions, differences, and applications of hole size and pitch in stainless steel perforated sheets.

1. What Is the Aperture of a Stainless Steel Perforated Sheet?

The aperture refers to the diameter of each hole on the surface of the perforated sheet. In most cases, especially with round hole patterns, this term indicates the actual diameter of each circular hole. For example, if a product description states “3mm hole size,” it means the diameter of each round hole is 3 millimeters.

It’s important to note that for other hole shapes—such as square holes, slotted holes, or hexagonal holes—the term “aperture” might be replaced by more specific descriptions like “hole width and length” or “hole side length.” However, for convenience, many manufacturers still use “aperture” as a generic term. When selecting a product, be sure to confirm the exact shape and dimensions being referred to.

2. What Is the Hole Pitch of a Stainless Steel Perforated Sheet?

Hole pitch refers to the distance between adjacent holes on the sheet. While the concept seems simple, there is often confusion in how it is defined. In the industry, two common interpretations exist:

Center-to-Center Pitch (Center Distance): This means the distance from the center of one hole to the center of the next. This is the most widely accepted and standardized definition, especially in engineering drawings and precise fabrication.

Edge-to-Edge Pitch: This refers to the distance from the edge of one hole to the edge of the adjacent hole. This can be more intuitive in practical applications, such as estimating material strength or airflow.

Therefore, when communicating with manufacturers, it’s essential to clearly state whether your specified hole pitch refers to center-to-center or edge-to-edge measurements to avoid misunderstandings during production.

3. How Do Aperture and Hole Pitch Affect Application?

The aperture and hole pitch of a stainless steel perforated sheet are more than just measurements—they directly influence the following factors:

Ventilation and Light Transmission: Larger apertures and tighter pitches offer higher open area ratios, making them ideal for filtration, ventilation, and light diffusion.

Load Capacity: Higher hole density can reduce the structural strength of the sheet. For load-bearing applications, a careful balance between hole size and pitch is necessary.

Aesthetic and Decorative Impact: In architectural applications such as facades, ceilings, or partitions, the combination of aperture and pitch affects visual appearance and design.

Cost and Material Efficiency: Smaller pitches typically require more processing and may increase material waste, thus affecting production costs.

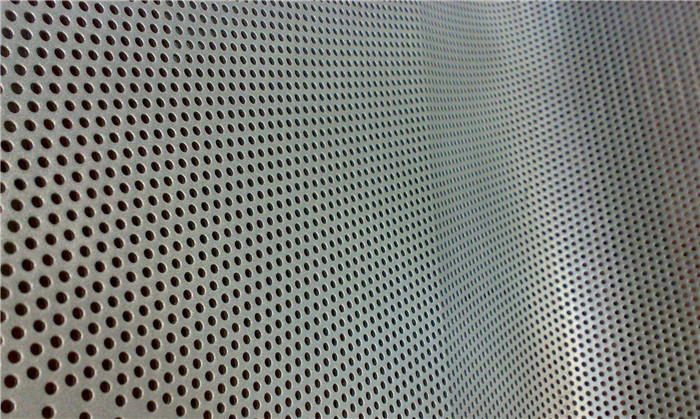

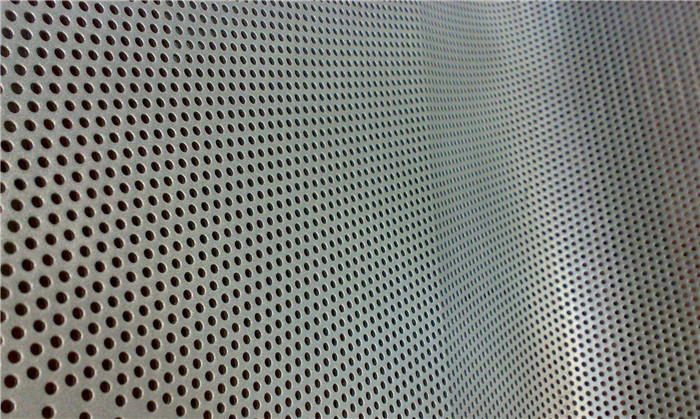

Stainless steel Perforated sheet

4. How to Select the Right Specification?

If you're selecting stainless steel perforated sheets for the first time, consider the following factors:

Define your usage scenario (e.g., ventilation, decoration, filtration, load-bearing)

Choose the hole shape (round, square, slot, hexagonal, etc.)

Confirm the aperture and hole pitch, and clearly specify whether it is center-to-center or edge-to-edge

Consult with experienced manufacturers to get samples or technical advice

5. Choose a Trusted Manufacturer for Quality Assurance

Anping County, known as China’s perforated sheet manufacturing hub, is home to many experienced producers. At Senchi Perforated Screen Factory, we specialize in custom manufacturing stainless steel perforated sheets with precise control over hole size, pitch, and layout. Our factory is equipped with advanced machinery and a skilled technical team ready to meet your unique requirements.

If you have any questions about selecting the right stainless steel perforated sheet, feel free to contact Senchi Perforated Screen Factory. We are committed to providing expert guidance and full-service support to help you find the best solution for your needs.