Custom Stainless Steel Perforated Sheets | Multiple Hole Types & Applications

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-10 21:39:28 Browse:

In modern manufacturing and construction industries, stainless steel perforated sheets have become an essential material due to their excellent mechanical strength, corrosion resistance, and versatile structural designs. As a professional perforated sheet manufacturer, we offer precision-made stainless steel perforated sheets tailored to various needs across industries, supporting customization in hole shapes, thickness, materials, and applications.

What Is a Stainless Steel Perforated Sheet?

A stainless steel perforated sheet refers to a metal sheet with regularly or irregularly spaced holes punched through its surface using mechanical or CNC equipment. While retaining the high durability and oxidation resistance of stainless steel, it also offers good ventilation, light transmission, filtration, and aesthetic value. These features make it widely applicable in decoration, screening, sound absorption, and protection purposes.

Common Hole Types Available

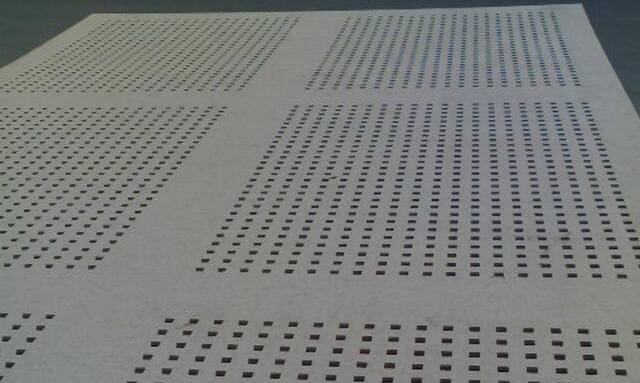

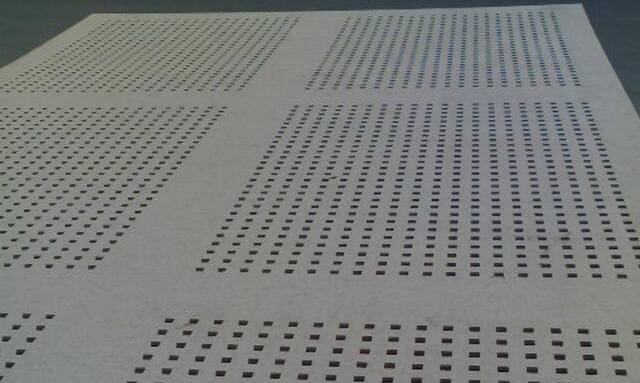

We offer a wide variety of perforation types to meet different needs. Round holes are the most common and can be arranged in straight or staggered rows, ideal for general applications. Square holes offer a more modern visual and are often used in ventilation systems and architectural decorations.

Long-slotted (oblong) holes, also known as rectangular holes, are suitable for ventilation and mechanical protection, offering both airflow and structural integrity. Hexagonal holes are commonly used for filtration due to their higher open area ratio. We also support custom patterns such as fish scale holes, plum blossom holes, or triangular holes for artistic or decorative applications.

Material Options and Thickness Range

We offer several stainless steel materials to meet diverse industry requirements. Type 304 stainless steel is the most widely used for its good corrosion resistance and workability, ideal for general environments. Type 316L offers superior anti-corrosion performance and is especially suitable for coastal or chemical exposure. Type 201 is a more cost-effective choice for light-duty decorative projects. Type 430 is magnetic and used in specialized mechanical setups.

We support thicknesses ranging from 0.3mm to 8.0mm. The most common usage thickness is between 1.0mm and 3.0mm, with full customization available upon request.

Stainless Steel Perforated Sheets

Manufacturing Process

Our production uses automated CNC punching machines, ensuring high-efficiency and high-precision hole forming. From raw material flattening, CAD layout, perforation, deburring, leveling, to surface finishing and packaging—every step follows strict quality protocols.

We also offer various surface treatments such as brushing, sandblasting, and electrolytic polishing, making our products not only functional but also aesthetically pleasing for architectural and display purposes.

Broad Applications Across Industries

Stainless steel perforated sheets are used across nearly every field that requires ventilation, filtration, aesthetic design, or acoustic control.

In architectural decoration, they are used for curtain walls, stair railings, partitions, and ceiling designs—combining functionality with visual appeal. In industrial settings, they serve as machine guards, ventilation grilles, filter covers, and cooling system panels. In the environmental sector, they are employed in dust removal equipment, exhaust systems, and noise control rooms.

They are also widely used in agriculture and food processing—for example, in grain sorting, feed processing, or as workstation surfaces in food machinery. Transportation facilities such as metro stations and railway platforms often use perforated panels for sunshades, security barriers, and ventilation covers.

Full Customization & Technical Support

We support custom fabrication based on hole shape, pattern, material, thickness, dimensions, and color. Clients can provide their own drawings or samples, and our team will offer technical advice to optimize functionality and cost-efficiency.

In addition to manufacturing, we provide design consultation, sample testing, and technical drawings, helping clients reduce trial-and-error and streamline project timelines.

Why Choose Us?

With over a decade of experience in stainless steel perforated sheet manufacturing, we have served numerous engineering and industrial clients across the country. Our facility is equipped with advanced CNC punching machines imported from Germany, ensuring precise and consistent hole quality.