Factors That Determine the Price of Perforated Metal Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-11 16:44:03 Browse:

When purchasing perforated metal sheets, pricing is often a primary concern. However, the cost of perforated sheets is not fixed—it is determined by a range of factors. Understanding these influencing elements will help you make better-informed purchasing decisions.

We are a professional manufacturer of perforated metal sheets, offering a wide variety of specifications and reliable quality. Whether you need standard or custom-made designs, we provide comprehensive solutions. Below, we break down the key factors that affect the price of perforated sheets.

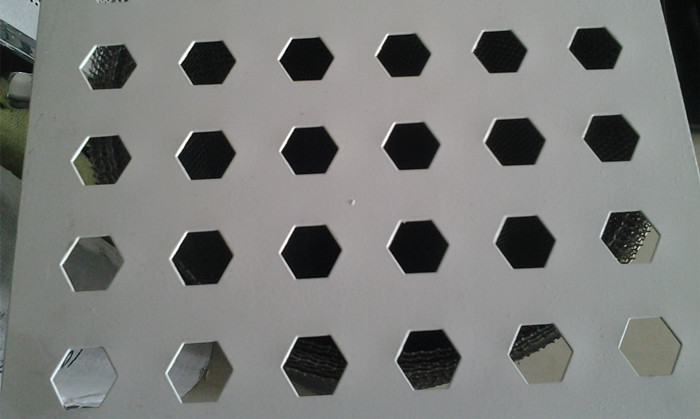

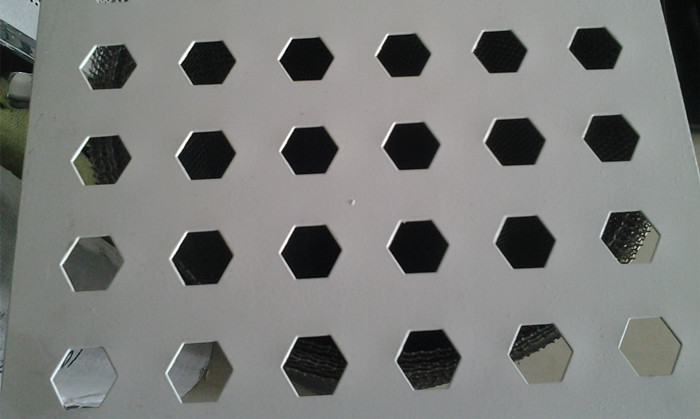

1. Hole Type Affects Production Complexity and Cost

The type of hole is the first major factor influencing the price of perforated metal. Each hole shape requires a different production process and tooling design, which impacts cost. We offer a wide range of hole types, including but not limited to:

Round holes, square holes, long round holes, oval holes, triangular holes, hexagonal holes, cross holes, diamond holes, plum blossom holes

Special designs like fish scale holes, louvered holes, star-shaped holes, octagonal holes, bulging holes, crocodile mouth holes, and more

Custom non-standard hole shapes based on customer drawings or requirements

Generally, the more complex the hole shape, the more intricate the tooling, and the higher the manufacturing cost.

Perforated metal sheets

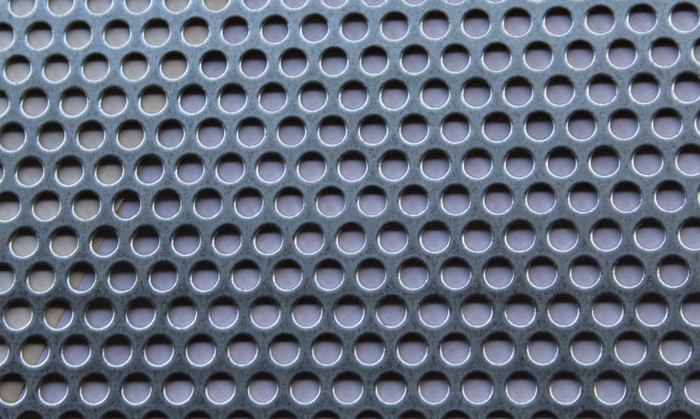

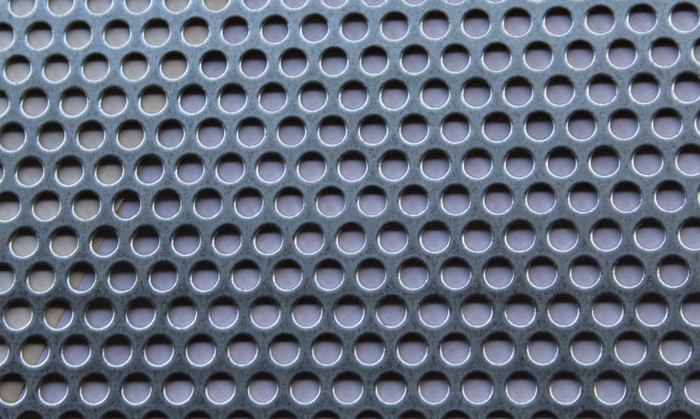

2. Hole Diameter Impacts Material Usage and Processing

Hole diameter is another crucial pricing factor. We can manufacture perforated sheets with hole diameters ranging from 0.5mm to 300mm. Smaller holes require higher precision, specialized tooling, and slower punching speeds, leading to higher production costs.

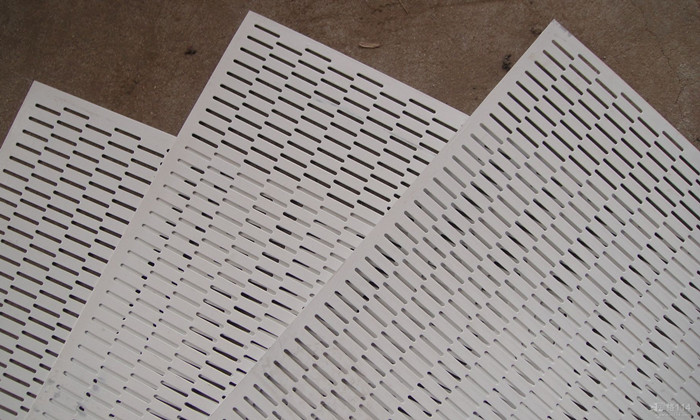

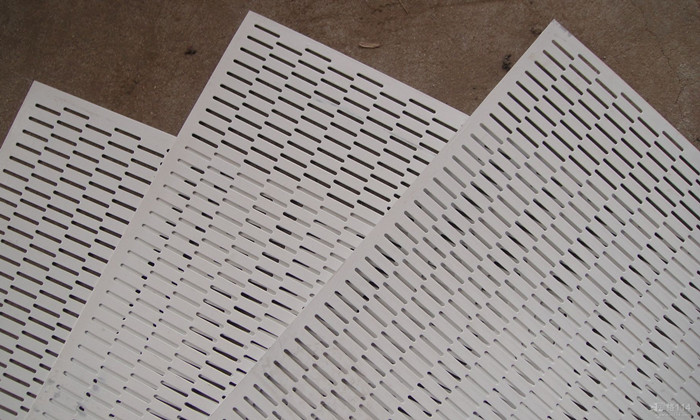

3. Open Area Ratio Influences Functionality and Price

The open area ratio refers to the percentage of metal removed by perforation. This is typically controlled by adjusting the spacing (pitch) between holes. A higher open area ratio means more metal is removed, reducing strength but improving ventilation and light transmission. A lower ratio offers greater strength and coverage.

We can customize hole spacing to meet your specific functional needs. Changes in open area will affect both material usage and production time, and thus influence pricing.

Perforated metal sheets

4. Material Type Determines Base Cost

Perforated metal sheets can be made from various types of metal, each with its own pricing and application characteristics. Common materials include:

Carbon Steel: Cold-rolled steel, hot-rolled steel, galvanized steel—affordable and suitable for general industrial use.

Stainless Steel: 201, 304, 316 grades—ideal for applications requiring corrosion resistance, such as food processing and chemical industries.

Non-Ferrous Metals: Aluminum, copper, manganese steel—used for decorative or specialized functional purposes.

The choice of material has a direct impact on both performance and cost.

5. Sheet Thickness Affects Processing Difficulty

Even when using the same material, different thicknesses will lead to different pricing. Thicker sheets require more force to perforate and cause more wear on the tooling, increasing manufacturing difficulty and cost.

Our perforated sheets are available in thicknesses ranging from 0.3mm to over 10mm, suitable for light-duty to heavy-duty applications.

Perforated metal sheets

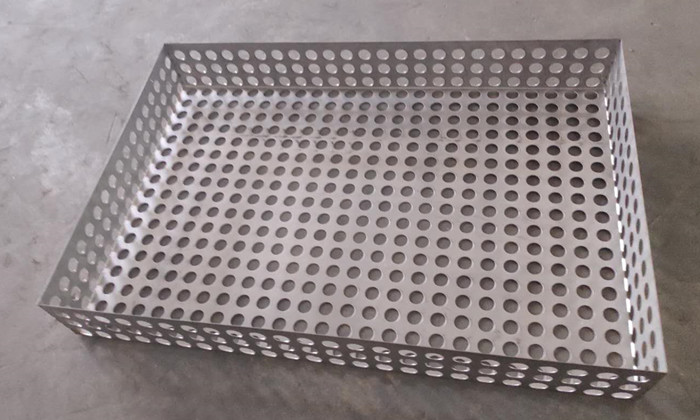

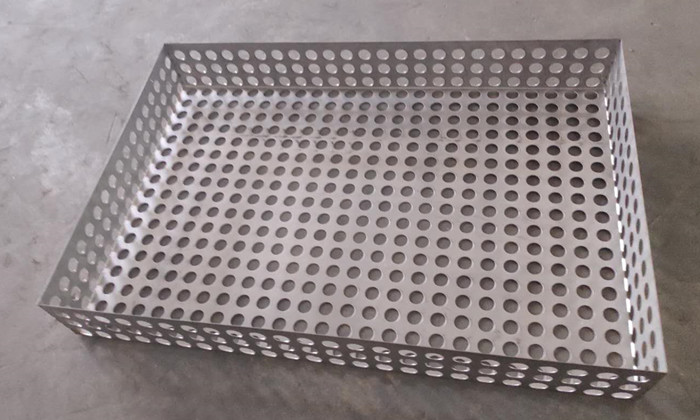

6. Secondary Processing Adds Value and Cost

In addition to basic perforation, we offer various post-processing services to meet specific installation or aesthetic needs, such as:

Fabrication: Bending, rolling, cutting, welding

Surface Treatments: Spraying, anodizing, polishing, powder coating

Precision Work: Laser cutting, CNC punching, custom shaping

These value-added services enhance product functionality and appearance but also contribute to the final cost. The more complex the processing, the higher the price.

How to Get an Accurate Quote?

Since perforated metal pricing depends on multiple variables, we recommend providing detailed specifications when requesting a quote, including:

Desired hole shape and size

Material type and thickness

Open area ratio or hole pitch

Required processing or surface treatment

Application environment or any special requirements

You can email us your specifications, and our experienced sales team will provide a fast and accurate quote tailored to your needs.

Perforated metal sheets

Conclusion

Perforated metal sheets are widely used in many industries, but their pricing is influenced by numerous technical and material factors. By understanding these elements—such as hole type, size, material, and processing—you can make smarter purchasing decisions and ensure cost-effectiveness.

We are committed to providing customized, high-quality perforated metal solutions to meet your exact requirements. Contact us today to learn more or to receive a free quotation.