Perforated Sheets: A Detailed Comparison Between Sheet Panels and Rolls

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-14 15:14:32 Browse:

Perforated sheet metal is a highly versatile material widely used in architectural design, mechanical processing, filtration, sound insulation, and many other industries. Based on their physical form, perforated sheets are generally divided into sheet panels and rolls. Although both belong to the category of perforated products, they vary significantly in terms of manufacturing methods, specifications, hole types, and application scenarios.

This article offers a comprehensive comparison of perforated sheet panels and rolls to help you choose the right product for your specific needs.

1. Definition and Physical Form

Perforated Sheet Panels

Sheet panels refer to perforated sheets sold as individual, flat pieces with standard dimensions. Common sizes include 1000mm × 2000mm, 1220mm × 2440mm, and more. Each panel is processed separately, ensuring uniform sizing, easy transport, and convenient installation.

Perforated Rolls

Rolls are produced in long, continuous strips of perforated metal, coiled into rolls. This form is especially suitable for applications requiring uninterrupted material use, such as production lines, filtration systems, or HVAC duct linings.

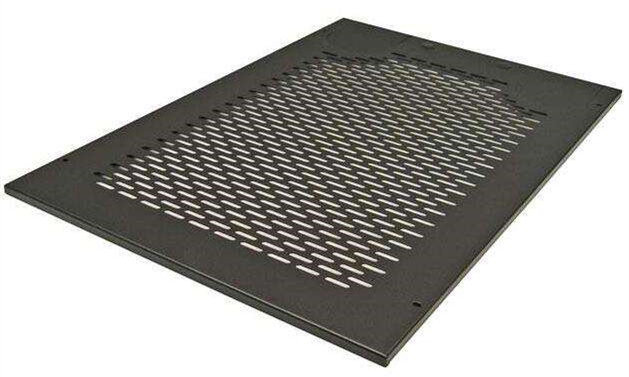

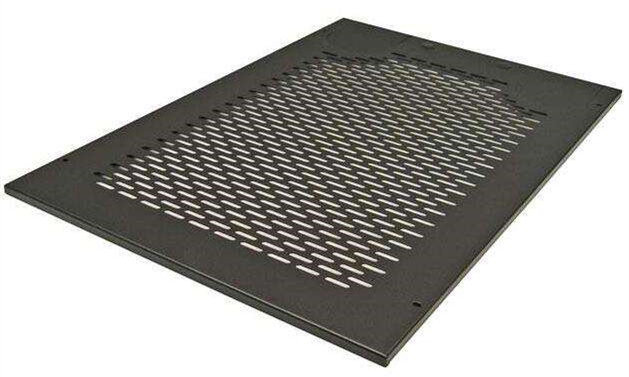

Perforated Sheet

2. Thickness and Hole Size Range

Perforated Rolls

Due to the limitations of the production process, perforated rolls are best suited for thin materials. The typical thickness range is 0.2mm to 1mm, with hole diameters ranging from 0.8mm to 15mm. This makes them ideal for lightweight, large-area applications where flexibility is important.

Perforated Sheet Panels

Sheet panels offer greater flexibility in material thickness and hole size. They can accommodate thicknesses from 0.3mm up to 20mm, with hole sizes ranging from 0.5mm to 200mm. This wide range makes them suitable for applications requiring structural strength or custom design.

3. Production Methods and Equipment

Perforated Rolls

Rolls are produced using gantry punching machines, which allow for fast, continuous production. These machines are highly efficient but limited in terms of hole variety and pattern complexity.

Perforated Sheet Panels

Sheet panels are manufactured with vertical punching machines equipped with automated feeding systems. Although the production speed is lower, this method supports a broader range of hole patterns and enables high customization—ideal for specialized industrial or decorative applications.

Perforated sheet

4. Hole Pattern Variety

Perforated Rolls

Currently, perforated rolls are primarily limited to round hole patterns. These are suitable for basic ventilation, filtration, or acoustic control.

Perforated Sheet Panels

Sheet panels can be manufactured with a wide variety of hole types. These include round holes, oval holes, long round holes, square holes, rectangular holes, triangular holes, star holes, hexagonal holes, figure-eight holes, cross holes, plum blossom holes, diamond holes, fish scale holes, louvered holes, raised round holes, crocodile mouth holes, and more. Custom patterns can also be created based on user requirements, making sheet panels ideal for decorative and specialized industrial purposes.

5. Application Scenarios and Selection Advice

If your project requires continuous use of thin material, quick production, and basic hole patterns, perforated rolls are the recommended option. Their flexibility and cost-effectiveness make them ideal for large-scale standard applications.

However, if your application involves thick materials, complex or decorative hole patterns, or customized sizes, perforated sheet panels are the better choice. They offer more structural stability and a higher level of customization, especially for high-end or tailored projects.

6. Conclusion

As a functional material, perforated sheet metal is used across countless industries. Choosing between sheet panels and rolls is crucial to ensuring optimal performance, cost-efficiency, and design compatibility.

Understanding the specific characteristics of both forms—such as thickness capacity, hole variety, and production flexibility—will help you make the right decision. Whether you need fast, large-volume production with simple patterns or high-precision, custom-designed metal sheets, selecting the correct type of perforated sheet can significantly improve your project's outcome.

As a professional perforated sheet manufacturer, we provide both high-quality rolls and sheet panels tailored to your exact needs. Contact us today for expert advice and reliable product solutions.