2. Common Challenges in Processing Perforated Metal Sheets

Despite their versatility, the processing of perforated metal sheets presents several challenges. Understanding these potential issues can help manufacturers reduce production errors and enhance efficiency.

2.1. High Heat During Cutting

Cutting generates significant heat, and due to low thermal conductivity in certain materials, this heat tends to accumulate around the punch and tool. This heat buildup can reduce tool life and processing efficiency while potentially damaging the metal sheet's surface quality.

2.2. Cutting Difficulty

The hardness, ductility, and toughness of perforated metal sheets make clean cutting difficult. This leads to accelerated tool wear, and the quality of the cut edge may be compromised, resulting in additional processing time and costs.

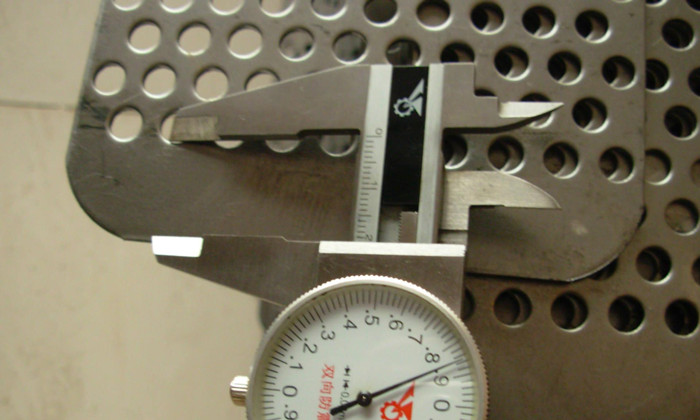

2.3. Risk of Deformation

Especially in austenitic stainless steel sheets, high elongation rates can lead to deformation during the punching process. This deformation complicates precision work and may lead to discrepancies in the final product, resulting in higher costs for rework or corrections.

2.4. Thermal Expansion

The accumulation of heat during the cutting and punching process causes metal expansion, adding complexity to the manufacturing process. Managing thermal expansion is critical to maintaining consistency in product dimensions.