2. Nickel: The Stability Enhancer of Corrosion Resistance

In addition to chromium, nickel also plays a crucial role in the rust resistance of stainless steel perforated sheet. Typically, premium stainless steel perforated sheet contains 8% to 11% nickel. Nickel strengthens the stability of the passive film formed by chromium, allowing it to remain intact even in more chemically aggressive environments.

In acidic or alkaline conditions, chromium alone may not provide long-lasting corrosion protection. However, the addition of nickel significantly improves the corrosion resistance of stainless steel perforated sheet, making it particularly suitable for marine, chemical, and food processing industries.

3. How Stainless Steel Perforated Sheet Resists Rust

Traditional carbon steel reacts with water, oxygen, and other corrosive elements to form iron oxides — the reddish-brown rust we commonly see. This rust not only affects appearance but also weakens the structure of the metal over time.

In contrast, the passive film on stainless steel perforated sheet acts like a natural shield, preventing these corrosive agents from penetrating. Even if the passive film is damaged during use, it can "self-heal" when re-exposed to air, quickly forming a new protective layer. This self-repairing ability is a key advantage of stainless steel perforated sheet over other metal materials.

That said, even stainless steel perforated sheet can face localized corrosion in extremely harsh environments, such as areas with high chloride concentrations. However, its overall resistance is significantly better than that of carbon or alloy steel.

4. Ideal for High-Demand Applications

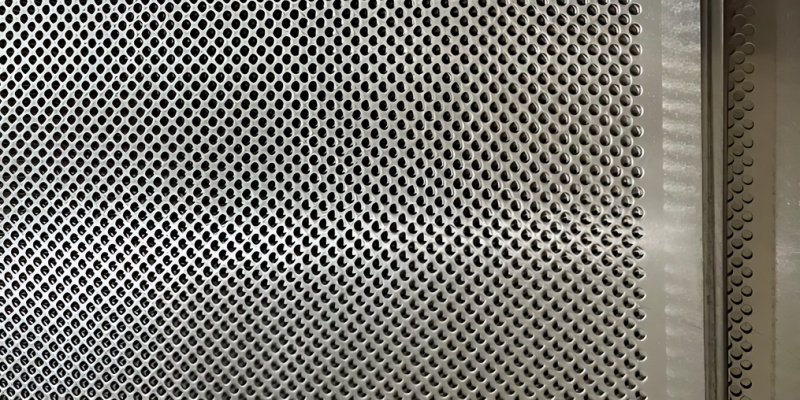

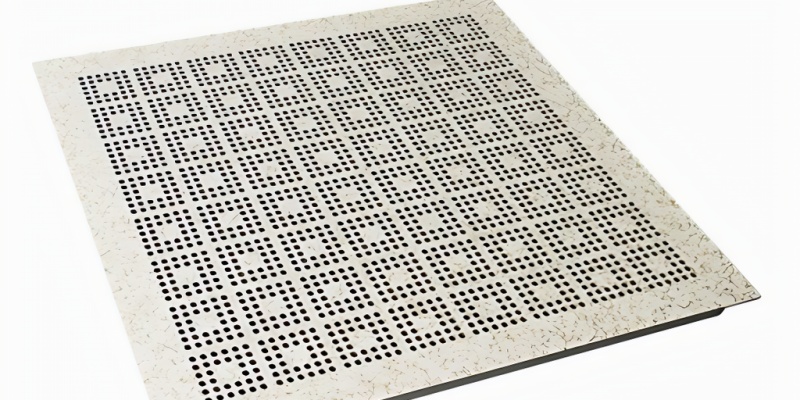

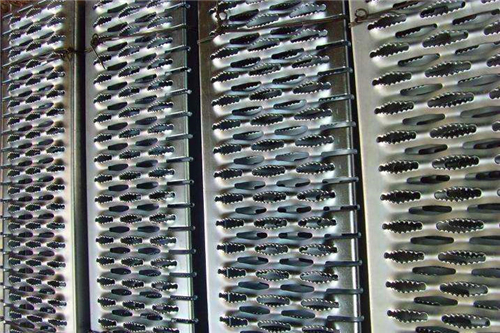

Not only is stainless steel perforated sheet rust-resistant, but its structural strength and clean appearance also make it a top choice across multiple industries. For example:

Architectural Design: Used in facades, ceilings, and stair railings for aesthetics and durability.

Transportation Industry: Applied in ventilation panels and flooring of vehicles where long-term corrosion resistance is critical.

Industrial Equipment: Commonly found in filters, protective covers, and electrical enclosures to extend service life.

Thanks to its excellent rust resistance, stainless steel perforated sheet helps reduce maintenance costs and extend service life, offering a cost-effective and high-performance material solution.

5. Smart Usage and Maintenance for Maximum Longevity

While stainless steel perforated sheet naturally resists corrosion, proper usage and maintenance are essential for maximizing its lifespan. Here are some key practices:

Regular Cleaning: Remove dust, salt, and chemical residues to prevent long-term corrosion buildup.

Avoid Physical Damage: Maintain the integrity of the passive film to reduce the risk of localized corrosion.

Choose the Right Grade: Select the appropriate stainless steel perforated sheet type based on the application environment, such as 304 or 316.

In coastal or chemical environments, choosing high-grade stainless steel perforated sheet and combining it with routine maintenance can ensure optimal performance and durability.