Expanded metal mesh, on the other hand, retains the original integrity of the sheet, making it structurally stronger per unit weight. Its interconnected pattern enhances strength, impact resistance, and durability. The mesh also provides excellent airflow and light transmission, making it suitable for heavy-duty applications where strength and ventilation are essential.

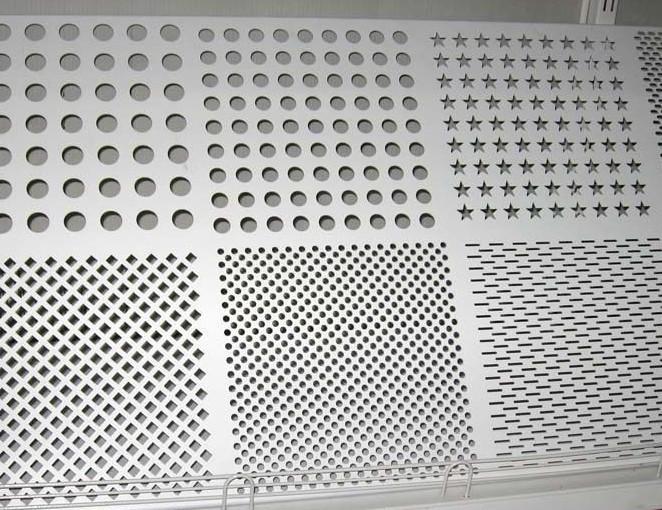

In terms of appearance, perforated metal sheets are often used in architectural and decorative contexts due to their refined surface and customizable hole shapes. Expanded metal mesh, while simpler in visual presentation, excels in functionality and mechanical performance.

Broad Application Scenarios

Perforated metal sheets are widely used in architectural facades, curtain walls, ceilings, and interior partitions. Their decorative patterns and shading capabilities make them a favorite among architects seeking modern, functional designs. They are also prominent in acoustic engineering—commonly used in metro stations, theaters, and airports as part of sound-absorbing wall systems.

In industrial sectors, perforated sheets are applied in filtration systems, particle separation, ventilation panels, and protective covers for machinery. Their precise perforations allow controlled airflow and particle filtration, making them essential in industries such as mining, food processing, pharmaceuticals, and petrochemicals.

Expanded metal mesh is commonly found in structural and protective applications. It’s ideal for elevated platforms, stair treads, and walkways due to its non-slip surface and load-bearing capabilities. In municipal engineering, it serves as highway fences, railway barriers, drainage grates, and ventilation covers—offering security, durability, and cost-effectiveness.

In agriculture and gardening, expanded metal mesh is used as fencing for poultry farms, orchards, and crop protection. Its corrosion resistance and ease of installation make it a practical solution for outdoor environments. It is also widely used as protective enclosures for industrial equipment, ensuring safety while allowing ventilation and heat dissipation.