What Is Hole Pitch?

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-08 11:31:58 Browse:

In the design and manufacturing process of perforated metal sheets, hole pitch is a crucial parameter. It not only affects the appearance and functionality of the sheet but also directly influences the structural strength and durability of the final product. This article explores the definition, measurement methods, design principles, and practical significance of hole pitch, providing a comprehensive understanding of this essential concept.

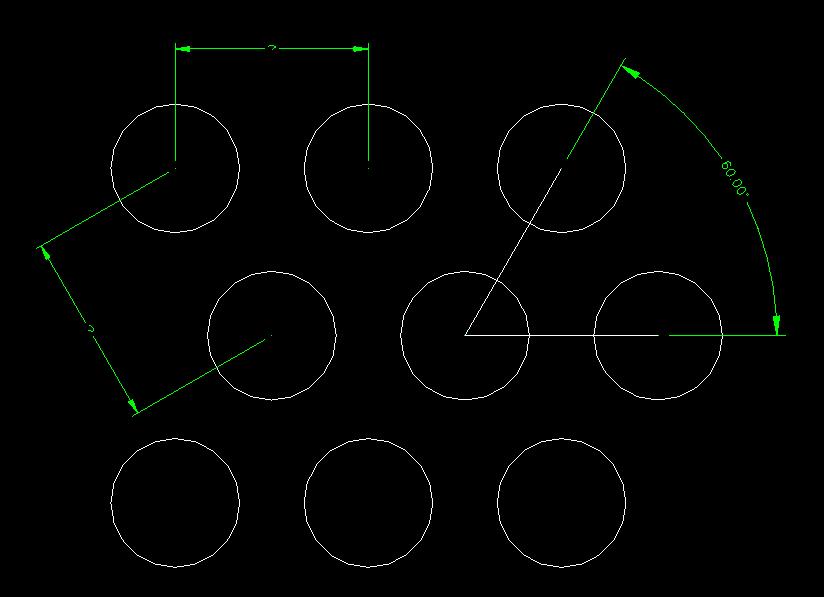

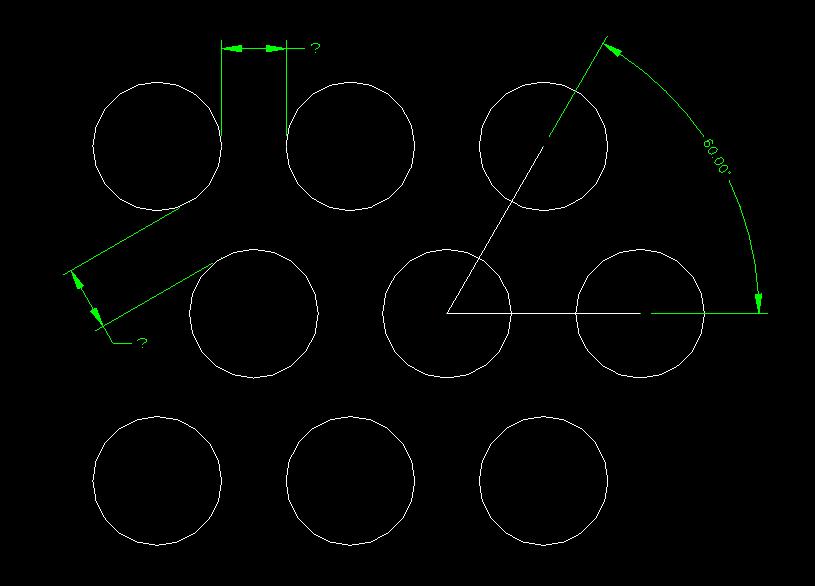

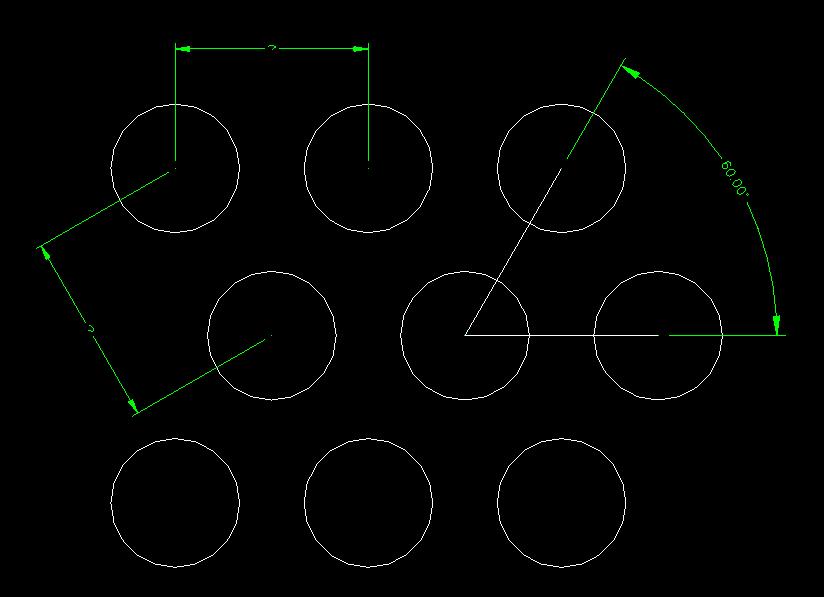

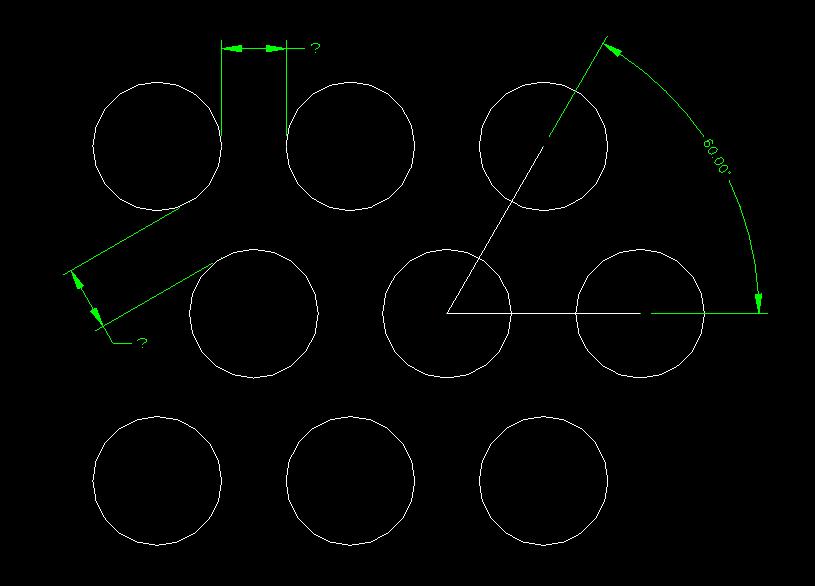

1. Center-to-Center Pitch

This is the most common measurement method and is typically used by manufacturers during quoting and production. It refers to the straight-line distance from the center of one hole to the center of the next. This method ensures uniform hole arrangement and is suitable for most industrial and architectural applications.

2. Edge-to-Edge Pitch

Edge-to-edge pitch refers to the distance from the edge of one hole to the edge of the adjacent hole. This measurement is critical in applications that require precise spacing—such as filters or decorative panels where uniformity is essential.

It is important to clarify which pitch measurement method is being used when designing or ordering a perforated sheet. Confusion between the two can lead to production errors and compromised product quality.

How Hole Pitch Affects Performance

Hole pitch significantly influences both the visual appearance and the mechanical properties of perforated metal sheets. Here are a few key effects:

1. Flatness of the Sheet

If the hole pitch is too small, it may cause warping or deformation during the punching process. For best results, the pitch should typically be at least 1.5 times the thickness of the material to maintain flatness during both production and usage.

2. Structural Strength

A very tight pitch can reduce the overall strength of the sheet and compromise its load-bearing capability. In applications requiring structural integrity, such as platforms or guards, the pitch must be carefully calculated to strike a balance between openness and strength.

3. Ventilation and Permeability

Hole pitch, combined with hole diameter, determines the open area ratio of a perforated sheet, which directly impacts airflow and filtration performance. For applications like air vents or speaker grilles, proper pitch selection ensures optimal functionality.

Design and Purchasing Recommendations

When designing or sourcing perforated metal sheets, keep these tips in mind:

Clearly Define Requirements: Choose the appropriate hole diameter, pitch, and open area based on application needs.

Clarify Measurement Method: Always specify whether center-to-center or edge-to-edge pitch is being used.

Consider Material Properties: Different metals behave differently under stress; adjust pitch accordingly.

Prototype First: Always verify the design with a sample before proceeding to mass production.

Conclusion

Hole pitch is a key factor in the design of perforated metal sheets, influencing both form and function. A well-designed pitch ensures aesthetic value, mechanical performance, and functional reliability. By understanding the role of hole pitch and incorporating best practices into your design and procurement process, you can ensure the success of your projects.

For more information about the design and fabrication of perforated sheets, feel free to explore our website or contact our technical team.