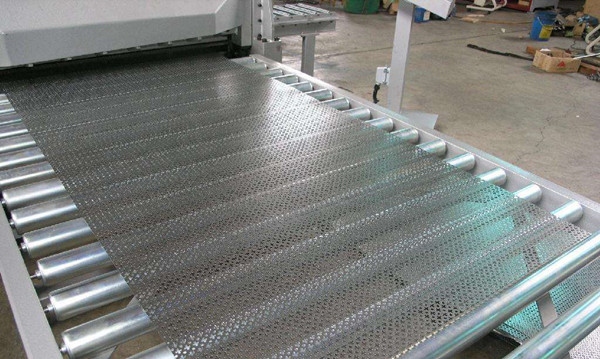

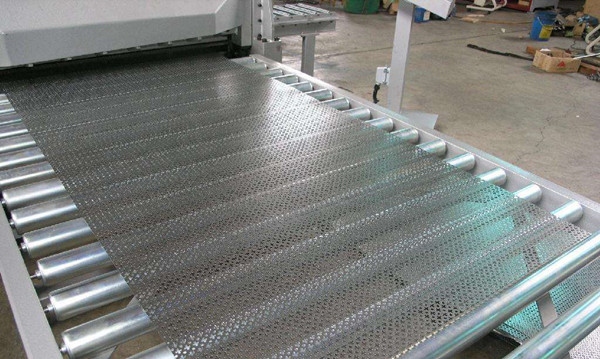

Effective Solutions for Deformation Issues in the Perforated Plate Production Process

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-14 15:45:50 Browse:

Deformation during the production of perforated plates is a common and often unavoidable issue. It typically arises from the characteristics of the punching process and the inherent properties of metal materials. Common types of deformation include warping, bending, and local sinking, which not only affect the appearance of the final product but can also complicate further processing and installation. Understanding how to effectively prevent and correct these issues is essential for maintaining high-quality production standards.

1. Leveling for Minor Deformation

If slight warping or unevenness is detected after perforation, the perforated plate can be corrected using a leveling machine. This is a widely used and straightforward method to restore flatness. The plate is passed through the leveling machine multiple times to gradually adjust its surface. For moderately deformed plates, additional passes and adjustments to the machine settings may be necessary to achieve satisfactory flatness. This treatment significantly improves both the visual and structural quality of the material, making it suitable for subsequent processing.

2. Maintaining Sharp Punches to Reduce Stress Concentration

The sharpness of the punch has a direct impact on how stress is distributed during the punching process. Dull or worn punches increase the risk of uneven force, which can cause localized deformation. To minimize this, punches should be inspected regularly and sharpened or replaced as needed. Using high-durability punch materials can also extend the service life and reduce deformation risk. Sharp punches ensure cleaner cuts and lower the internal stress introduced to the perforated plate during processing.

3. Optimizing the Punching Process

Properly optimized punching parameters play a critical role in minimizing deformation. Factors such as material thickness, hardness, and ductility should inform the selection of punching speed, pressure, and die design. Avoiding excessive speed and impact force helps prevent material distortion. The die structure should allow for balanced force distribution and efficient scrap removal. Paying attention to these technical details is especially important when dealing with thin or large-format perforated plates, where improper handling can lead to significant deformation.

4. Applying Heat Treatment or Annealing

For thinner or harder perforated plates, heat treatment or annealing is highly recommended. These processes help relieve internal stress accumulated during punching and improve material plasticity. Annealing, in particular, is effective for materials like stainless steel or copper, which are prone to stress-induced deformation. This treatment not only enhances the plate’s stability but also improves consistency and workability across the entire production batch.

5. Enhancing Support and Clamping During Processing

Without adequate support or clamping, perforated plates are likely to shift or warp during punching and shearing. This is particularly true for large or thin plates. To prevent this, make sure the material is firmly secured throughout the entire processing stage. Specialized supports, suction devices, or clamps can help maintain the plate’s position and ensure precision in hole placement and cutting.

6. Strengthening Quality Control and Monitoring

Beyond the technical processes, implementing a robust quality management system is crucial. From raw material inspection to in-process monitoring and final product checks, every stage should follow standardized procedures. Use measuring tools to quantify flatness, and integrate automated alerts or visual inspections to detect abnormalities early. Data recording and analysis also play an essential role in continuous improvement, helping refine processes and reduce the overall deformation rate.

Conclusion

As a key material used in construction, mechanical equipment, filtration, and ventilation systems, the quality of perforated plates directly impacts performance and customer satisfaction. By applying methods such as leveling, heat treatment, punch optimization, and enhanced support, manufacturers can significantly reduce the occurrence of deformation. Coupled with systematic quality control, these strategies ensure the production of high-precision, flat, and reliable perforated plates, reinforcing your brand’s reputation for quality and professionalism.