1. Welding Installation – For Large Public Buildings

Welding is commonly used in large public buildings such as exhibition centers and airport terminals, where structural strength is critical. This method ensures solid connections and high load-bearing capacity against wind and vibrations.

Construction Process:

Base Treatment:

The base surface is sandblasted to a cleanliness grade of SA 2.5, ensuring welding quality.

Spot Welding Positioning:

TIG welding is used for initial positioning, with spot welds spaced 250–300 mm apart.

Full Welding:

Pulse MIG welding is applied, maintaining a heat input between 8–10 kJ/cm to guarantee seam integrity.

Anti-Corrosion Coating:

After welding, a zinc-rich spray (zinc content ≥85%) is applied over seams with a minimum coating thickness of 120 μm.

Key Quality Control Points:

Use ER5356 filler wire for compatibility with 6061-T6 aluminum alloy.

Inter-pass temperature should not exceed 120°C; monitored with infrared thermometers.

2. Screw Fixing – For Commercial Spaces

Screw fixing offers flexibility and ease of installation, making it ideal for commercial projects like malls and office buildings.

Installation Methods:

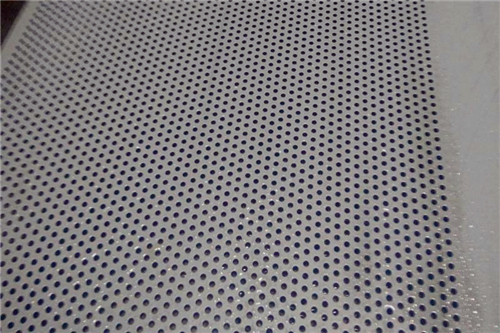

Pre-Drilled Hole Fixing:

Hole Spacing: 500 mm vertically and 350 mm horizontally.

Fasteners: Use M6 stainless steel screws with torque controlled at 1.5 N·m.

Sealant: Apply neutral silicone with a minimum 3 mm seam for waterproofing.

Direct Self-Tapping Screw Fixing:

Applicable Thickness: For aluminum panels 1.2–2.0 mm thick.

Drilling Tools: Use carbide step drill bits at 600–800 RPM.

Pull-Out Strength: Minimum pull-out force of each point should reach 180 N.

3. Clip-On System – For Interior Design

Clip-on systems avoid wall damage and are ideal for settings requiring easy disassembly and aesthetics, such as meeting rooms and galleries.

Fabrication & Installation Essentials:

Bending Accuracy:

CNC bending machines control the angle deviation within ±0.1°.

Mold Parameters:

Die opening = 8× panel thickness; bending pressure = 10 tons per mm of panel; hold time ≥3 seconds.

On-Site Installation:

Positioning: Use laser projectors to maintain alignment error within 1 mm per 10 meters.

Clip Spacing: 400–450 mm with a 5 mm thermal expansion gap.

Noise Reduction: Nylon pads with molybdenum disulfide reduce operational noise at joints.

4. Installation Quality Standards

Flatness:

Deviation under a 2-meter straightedge must not exceed 1.5 mm.

Seam Uniformity:

Seam width deviation should not exceed 0.3 mm for aesthetic consistency.

Corrosion Resistance:

Must pass 1,000-hour ASTM B117 salt spray test.

Seismic Performance:

Compliant with EN 1998-1 standards; maximum displacement ≤15 mm.

Conclusion

Choosing the right aluminum panel installation method enhances not only the visual appeal but also the durability and safety of your project. Depending on structural needs, construction conditions, and long-term maintenance, selecting the appropriate approach—welding, screw fixing, or clip-on—is essential for optimal results.