Dimensional Tolerance and Cutting Methods for Stainless Steel Perforated Sheet

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-14 16:29:03 Browse:

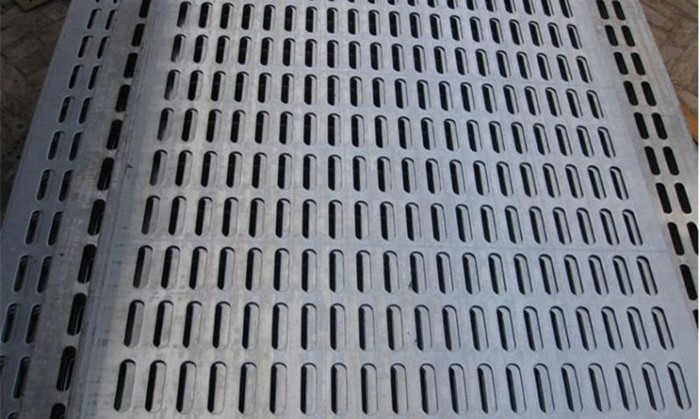

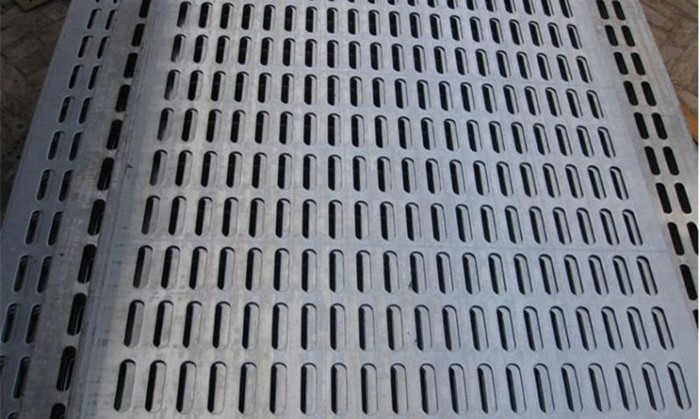

Stainless steel perforated sheets are widely used in architectural decoration, mechanical protection, ventilation systems, and filtration equipment. In practical applications, dimensional accuracy is essential. To meet the diverse requirements across industries, stainless steel perforated sheets must comply with strict dimensional tolerance standards. This article introduces the raw materials, cutting methods, and the corresponding tolerance levels to help customers better understand product specifications and select the most suitable processing method.

1. Raw Material and Standard Widths of Stainless Steel Perforated Sheets

The raw material for stainless steel perforated sheets is mainly stainless steel coil, which is processed through cutting and leveling. Standard coil widths typically include 1000mm (1 meter), 1200mm (1.2 meters), and 1500mm (1.5 meters). The coil is cut into sheets of fixed lengths according to customer needs. However, in many cases, the required width of the perforated sheet does not match the standard coil width. In such cases, further cutting is necessary to achieve the specified custom dimensions.

2. Common Cutting Methods for Stainless Steel Perforated Sheets

In actual production, we primarily use two cutting methods to produce stainless steel perforated sheets:

2.1 Shear Cutting (Mechanical Shearing)

Shear cutting is a traditional and efficient method, widely used for standard-sized perforated sheets. The dimensional tolerance of sheets cut with a shear machine is generally within ±1mm. This method offers the advantage of fast processing speed and low cost, making it ideal for customers who do not require high precision.

For example, in construction projects involving ventilation and protection panels, shear cutting is often sufficient and helps significantly reduce production costs while ensuring functionality.

2.2 Laser Cutting (High-Precision Cutting)

For customers who require higher precision—such as those in precision equipment manufacturing or custom architectural applications—we recommend laser cutting. This method offers extremely high accuracy, with dimensional tolerances controlled within ±0.3mm. Laser cutting ensures clean edges, tight tolerances, and excellent fitment for precision assembly.

Although laser cutting is more expensive than shear cutting, it delivers superior quality and is highly suitable for high-end manufacturing projects that demand detailed accuracy.

stainless steel perforated sheet

3. How to Choose the Right Cutting Method?

When selecting a cutting method for stainless steel perforated sheets, we suggest that customers consider the following factors:

Tolerance Requirements: If standard tolerances are acceptable, shear cutting is sufficient. For high-precision applications, laser cutting is recommended.

Cost Considerations: Laser cutting has a higher cost and is suitable for high-value or customized projects. Shear cutting is more economical for standard use.

Production Efficiency: Shear cutting is fast and efficient for bulk orders. Laser cutting is ideal for small-batch or custom-sized sheets.

4. Conclusion

Stainless steel perforated sheets are widely used in modern industry and architecture, and precise dimensional control plays a critical role in performance. By choosing the right cutting method, you can ensure product quality, control production costs, and optimize efficiency.

If you have any questions about stainless steel perforated sheet dimensions, tolerance levels, cutting techniques, or custom solutions, please feel free to contact our technical team. We are here to provide tailored support and professional advice.