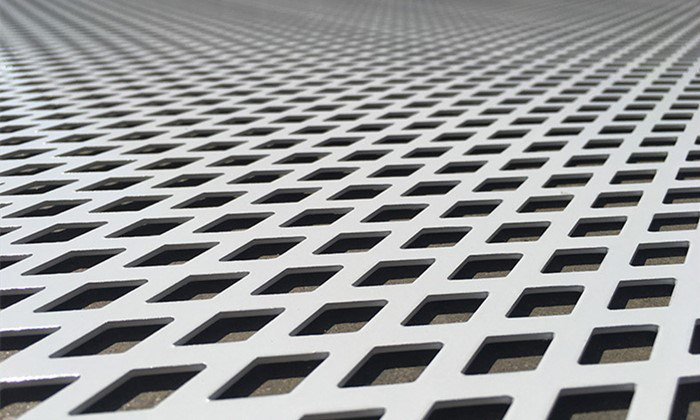

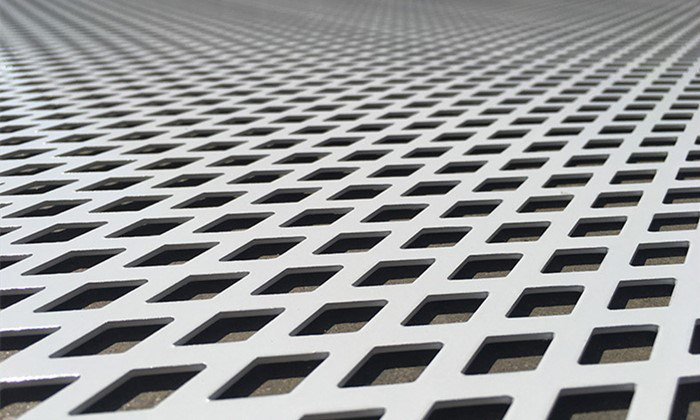

Causes and Solutions for Burrs on the Back of Stainless Steel Perforated Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-08 11:57:01 Browse:

In the manufacturing process of stainless steel perforated sheets, precision and surface finish are key indicators of product quality. However, burrs often appear on the backside of the sheet after punching, which can affect the product’s appearance, complicate further processing, or even pose safety risks. So, what causes these burrs, and how can they be minimized or eliminated? This article provides a technical analysis of the issue and outlines practical solutions.

1.1 Improper Die Clearance Design

In punching operations, die clearance plays a crucial role in cutting quality. Die clearance refers to the gap between the upper punch and the lower die. Ideally, the clearance should be precisely calculated based on the material and thickness of the stainless steel perforated sheet. Excessive clearance leads to tearing instead of clean cutting, which causes burrs. On the other hand, too narrow a clearance increases tool wear and may damage the die.

1.2 Worn Punch or Die

With continuous use, the cutting edges of punches and dies can wear down. A dull punch cannot shear the material cleanly and will tear it instead, leaving burrs on the reverse side. This issue becomes especially prominent when processing hard stainless steel sheets.

1.3 Inconsistent Material Quality

Stainless steel sheets with surface oxidation, microcracks, or inconsistent hardness can exacerbate burr formation during punching. These material flaws affect the shearing process, causing uneven edges and deformations.

1.4 Improper Press Speed or Force Settings

The speed and pressure of the punching machine also directly affect the quality of the cut. If the press is too fast or not powerful enough, it may not complete a full shear cycle, resulting in torn edges and burrs on the back of the stainless steel perforated sheet.

Stainless steel perforated sheet

2. Effective Solutions to Reduce Burr Formation

2.1 Optimize Die Design

Select proper die clearance according to the sheet thickness and material type. For instance, for stainless steel perforated sheets with a thickness of 0.5mm to 1.5mm, a die clearance of 6% to 10% of the thickness is recommended. Always ensure the die edges are sharp and well-maintained.

2.2 Establish Regular Tool Maintenance

Implement a regular inspection and maintenance schedule for punches and dies. Replace or sharpen tools as needed to maintain optimal cutting performance.

2.3 Adjust Press Parameters

Properly adjust punching speed and force according to material type. Avoid high-speed operations that may compromise cut quality. In some cases, multi-stage feeding or secondary punching can improve results and reduce burrs.

2.4 Ensure High-Quality Raw Materials

Use stainless steel sheets with uniform hardness, flat surfaces, and no visible defects. High-quality raw materials are essential for clean and consistent punching.

2.5 Apply Post-Processing Deburring Techniques

For burrs that already exist, apply secondary processing methods such as grinding, vibratory deburring, acid pickling, or laser deburring. These methods improve surface smoothness and ensure that the stainless steel perforated sheet meets higher industry standards.

3. Conclusion

Burrs on the back of stainless steel perforated sheets are a common but controllable issue in punching operations. Through optimized die clearance, proper maintenance, quality materials, and suitable process parameters, manufacturers can significantly reduce burrs and improve product performance.

For companies focused on high-quality production, paying attention to every detail is not just a technical requirement—it’s also a reflection of brand integrity and customer satisfaction. Enhancing the quality of stainless steel perforated sheets can give your business a competitive edge in today’s demanding market.

If you’re facing challenges with burrs in your production line, feel free to contact us. Our technical team is ready to provide tailored solutions to support your manufacturing needs.