Comprehensive Guide to Perforated Metal Sheets: Material Types and Applications

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-05-09 10:11:30 Browse:

I. Overview of the Diversified Materials for Perforated Sheets

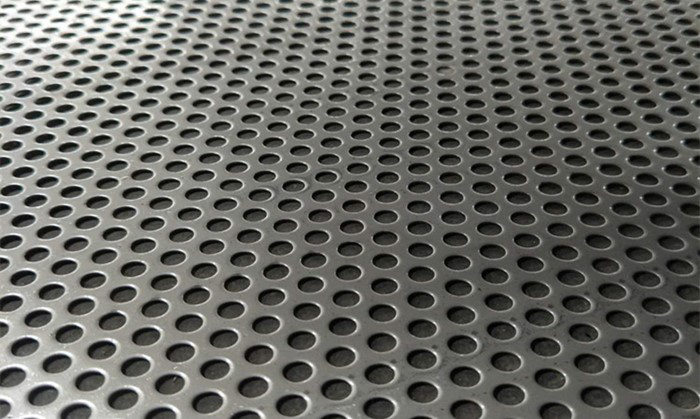

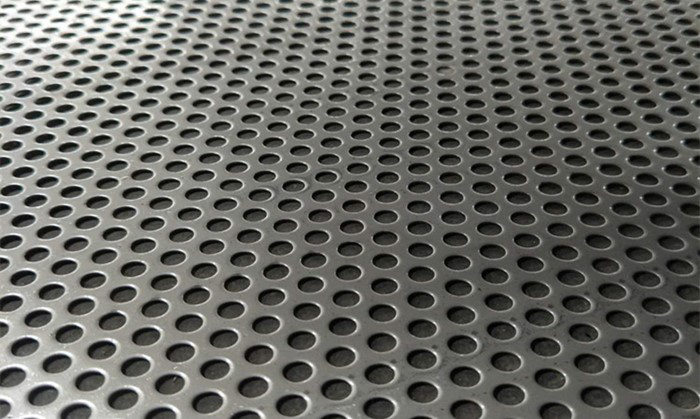

Perforated sheets are special metal plates with regularly arranged holes punched into the surface to serve various functional purposes such as ventilation, drainage, decoration, or weight reduction. Due to their wide range of applications—from building facades and interior decoration to industrial filtration and protective fencing—almost all common metal sheet types available on the market can be processed into perforated sheets. Based on processing methods and usage scenarios, the most commonly used sheet materials can be generally categorized into three main types: iron-based, aluminum-based, and stainless steel.

Iron perforated sheets are widely used for their durability and relatively low cost. Common types include:

Cold-rolled Sheets: Smooth surface with high thickness precision, suitable for applications requiring superior appearance;

Hot-rolled Sheets: Economical and easy to process, typically used for outdoor fences, stair treads, and other structural parts;

Galvanized Sheets: Coated with zinc to resist corrosion, ideal for outdoor or humid environments;

Manganese Steel Sheets: High hardness and excellent wear resistance, often used in heavy-load or impact-resistant engineering applications.

This wide selection makes iron perforated sheets suitable not only for aesthetic purposes but also allows for tailored choices based on the durability needs of specific environments.

Aluminum perforated sheets are lightweight, corrosion-resistant, and easy to process, making them a popular choice in modern architecture and interior design. Based on alloy composition and performance, they can be divided into several series:

1xxx Series (Pure Aluminum): Simple composition with excellent ductility, though lower in strength;

2xxx Series (Aluminum-Copper Alloys): High strength, commonly used in aerospace and structural components;

3xxx Series (Aluminum-Manganese Alloys): Outstanding corrosion resistance, widely used in the chemical and food industries;

4xxx Series (Aluminum-Silicon Alloys): Lower melting point with good weldability, suitable for welded structures;

5xxx Series (Aluminum-Magnesium Alloys): Excellent mechanical and corrosion resistance, preferred for building facades and shipbuilding.

From exterior cladding to interior partitions, aluminum perforated sheets meet a variety of design and usage requirements through the unique features of each alloy series.

perforated sheet

Stainless steel perforated sheets offer excellent corrosion resistance, high-temperature endurance, and strength, making them ideal for food processing, medical equipment, machinery protection, and architectural decoration. Common grades include:

201 Stainless Steel: Lower cost and moderate corrosion resistance, suitable for indoor decorative use;

304 Stainless Steel: Most widely used grade with balanced corrosion resistance and formability;

316 Stainless Steel: Higher molybdenum content for superior resistance to salt spray and chemical corrosion, often used in marine or chemical environments;

409 Stainless Steel: Designed for exhaust systems and high-temperature applications with strong oxidation resistance;

430 Stainless Steel: General corrosion resistance with strong magnetic properties, commonly seen in household appliances and interior design.

By selecting the appropriate stainless steel grade, users can strike a balance between cost and performance, while precisely matching environmental requirements.

Whether for structural engineering, decorative aesthetics, or functional performance, perforated metal sheets can be manufactured from a wide range of materials including iron, aluminum, and stainless steel. You can select the most suitable material and grade based on your project budget, usage environment, and visual preferences to ensure both performance and cost-efficiency. For custom production or further consultation, feel free to contact us anytime.