Precision Perforated Plate Processing and Customization Services

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-05-09 10:24:50 Browse:

Precision Perforating Process Introduction

In today’s manufacturing landscape, specialized perforated plates serve critical roles in filtration, decoration, and safety protection. Leveraging high‑precision CNC punching equipment, our company efficiently processes metal sheets to your exact specifications. Whether you require large‑volume production or small‑batch customization, our stable processes and rigorous quality inspections deliver perforated plates in a variety of shapes and exact dimensions, ensuring reliable performance and consistency.

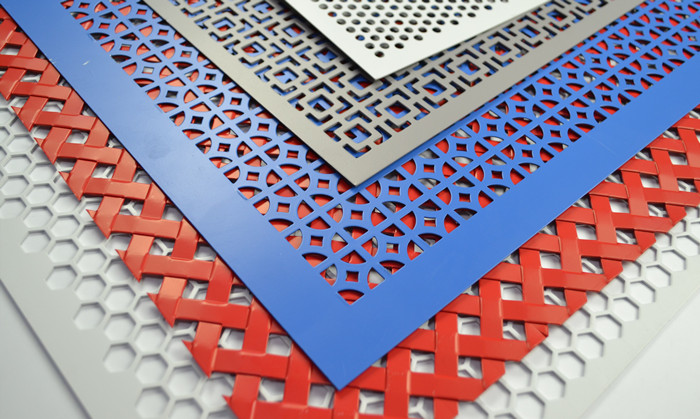

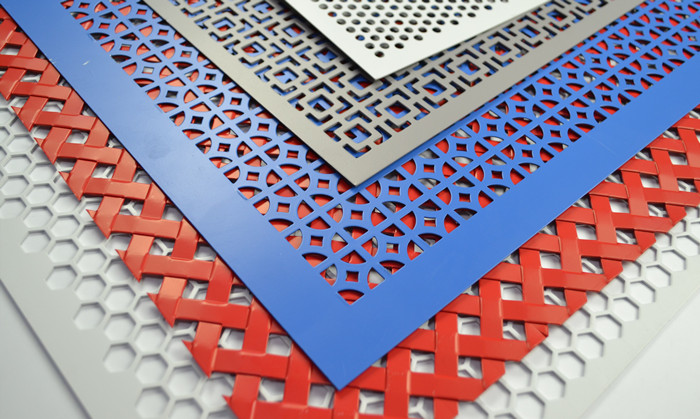

Customizable Hole Types

Our extensive collection of punching dies enables us to create virtually any hole pattern you envision, including:

Round, oval, and slotted holes

Square, rectangular, triangular, and hexagonal holes

Star‑shaped, flower (chrysanthemum) and fish‑scale patterns

Grating and crossed holes

Fully bespoke, irregular patterns or branded logos

From functional screening to artistic façades, we tailor each perforated plate to your application.

Perforated plate

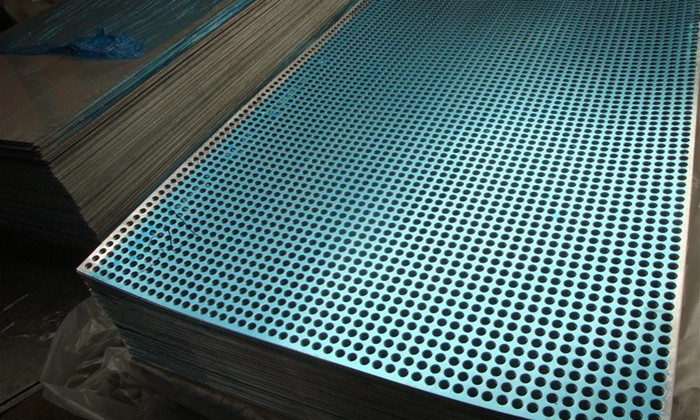

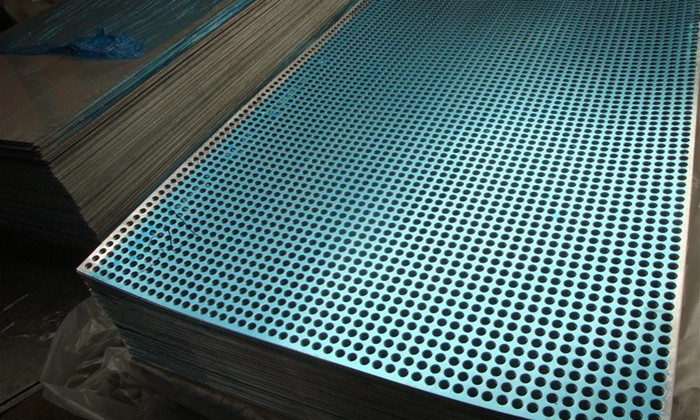

Hole Diameter and Plate Thickness Matching

We manufacture perforated plates with hole diameters ranging from 0.1 mm to 20 mm. To maintain plate strength and edge quality, we generally recommend a minimum hole diameter not less than the sheet thickness. This guideline prevents deformation during punching and enhances the longevity of the plate, while ensuring precise downstream processes such as welding, bending, or surface treatment.

Perforated plate

Multiple Metal Materials Available

Choose from a wide array of base materials to suit your project requirements:

Carbon Steel: cold‑rolled, hot‑rolled, galvanized, manganese steel

Specialty Alloys: copper, titanium, and more upon request

Our material expertise ensures optimal performance in corrosive, high‑temperature, or decorative environments.

Perforated plate

Services and Support

From initial design consultation and die manufacturing to precision punching, bending, surface finishing, and packaging, our experienced technical team oversees every step. Whether for industrial filtration, curtain wall decoration, enclosure cooling, or safety guards, we provide comprehensive, turnkey solutions. Contact us today to discuss your perforated plate requirements and discover the perfect custom solution.