A Comprehensive Guide to Perforated Plate Prices

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-05-09 10:20:28 Browse:

In practical engineering and decorative applications, perforated plates are highly favored for their excellent ventilation, filtration, safety protection, and aesthetic appeal. However, prices for plates of identical specifications can vary by several times on the market. This disparity mainly arises from differences in material, hole pattern, plate thickness, and processing methods. This article analyzes the components of perforated plate pricing from multiple angles to help you quickly understand market trends and accurately manage your cost budget.

1. Core Factors Affecting Perforated Plate Price

1.1 Material Type

Carbon Steel (Iron Plate): Ranges from ¥10 to ¥300 per m². Options include cold-rolled, hot-rolled, galvanized, or manganese steel, each with differing raw material costs.

Aluminum Alloy: Average market price is ¥15 to ¥380 per m². Common series include 1000, 2000, 3000, 4000, and 5000; alloy grade, thickness, and machining difficulty determine cost fluctuations.

Stainless Steel: Priced between ¥30 and ¥3,000 per m². Popular grades are 201, 304, 316, 409, and 430. Higher-grade stainless steels offer superior corrosion resistance and mechanical properties, leading to higher unit costs.

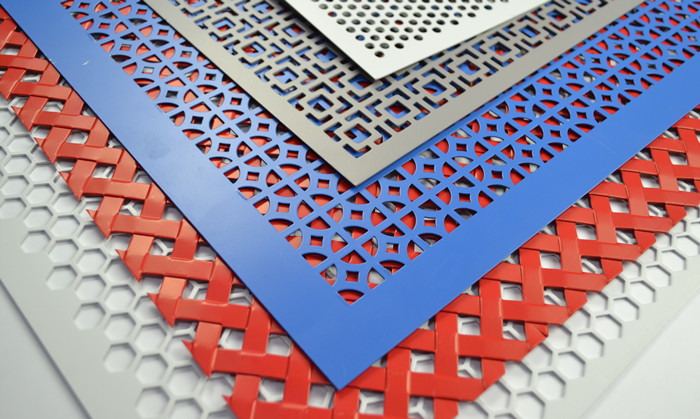

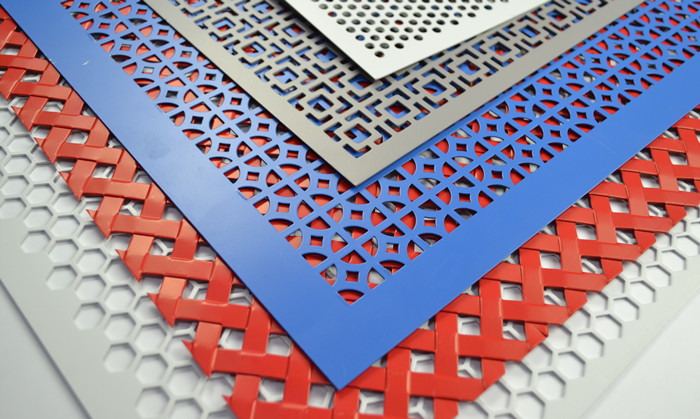

1.2 Hole Pattern and Diameter

Standard Patterns: Round holes, oval holes, slotted holes, square holes, rectangular holes, and triangular holes.

Special Patterns: Pentagrams, hexagons, octagons, cross shapes, fish-scale patterns, slot grooves, raised round holes, crocodile-mouth holes, etc.

The smaller the hole diameter and the tighter the pitch, the greater the machining difficulty and number of punching operations. Material waste and machine wear also increase, naturally raising the price.

perforated sheet

1.3 Plate Thickness

Thin Plates (0.1–2 mm): Lower raw material cost but may require more precision handling.

Thick Plates (2–20 mm): Higher material cost and longer processing times on punching machines, resulting in higher per-square-meter prices.

1.4 Processing Method

CNC Punching: Suited for small to medium batches; mold costs are low but single-hole efficiency is moderate.

Laser Cutting: Offers high precision and supports complex designs, but equipment and consumable costs are relatively high.

Roll Forming: Ideal for large-volume, regular hole production; high efficiency requires dedicated molds.

perforated sheet

2. How to Obtain an Accurate Quote

Specify Material Requirements: Indicate the material type (carbon steel, aluminum alloy, or stainless steel) and the grade.

Confirm Plate Specifications: Provide plate thickness, length, width, and other dimensions.

Detail Hole Pattern and Pitch: For example, round holes φ5 mm with 10 mm pitch; for special shapes, include a diagram.

Quantity and Finishing: Order volume and surface treatments (e.g., painting, plating, anodizing) also affect total cost.

With these parameters, we can promptly prepare a customized perforated plate price list and offer sample confirmation services, ensuring product quality and delivery timelines meet your project needs.

perforated sheet

For detailed inquiries or sample quotations, click the online chat icon at the bottom right of our website or call our hotline directly. With professional manufacturing and premium service, Senchi Wire Mesh is trusted by industry peers. We look forward to partnering with you to create exceptional value.