Comprehensive Guide to 304 Stainless Steel Perforated Sheet: Specifications, Benefits, and Applications

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-07 14:43:32 Browse:

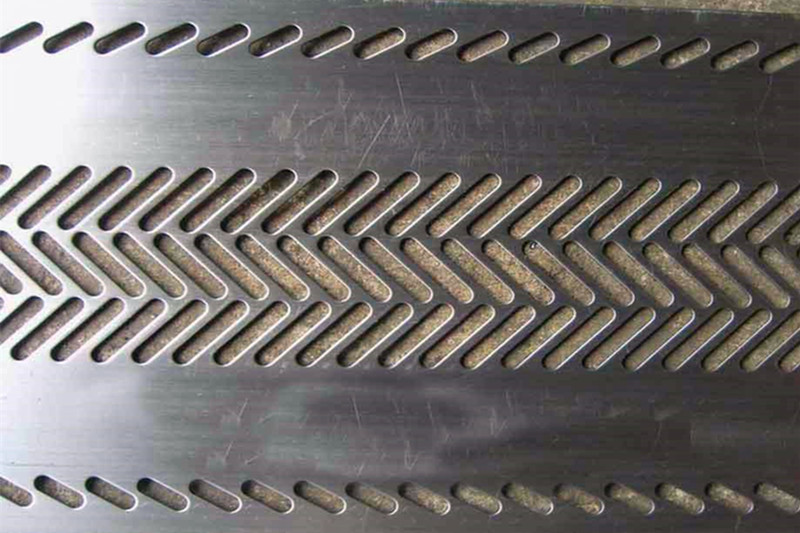

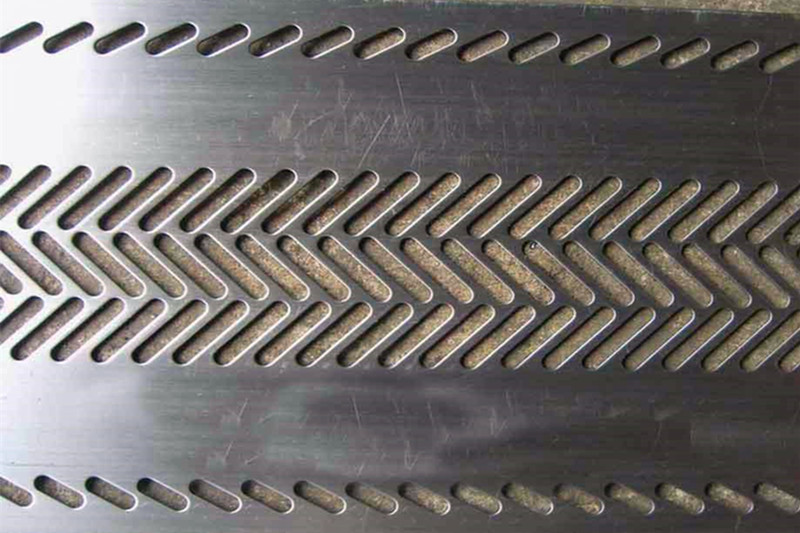

The 304 stainless steel perforated sheet is made from high-quality 304 stainless steel through precise punching processes. With excellent corrosion resistance, high-temperature tolerance, and strong mechanical properties, it is widely used in construction decoration, mechanical protection, screening, filtration, and more.

Key features of 304 stainless steel include:

Excellent Corrosion Resistance: Performs well in acidic and alkaline environments, ideal for chemical and food industries.

High-Temperature Resistance: Maintains strength and hardness under high temperatures, suitable for thermal systems.

Superior Mechanical Strength: Offers good ductility and toughness, allowing flexible fabrication into various shapes and sizes.

2. Diverse Hole Types and Specifications

The 304 stainless steel perforated sheet can be customized with various hole shapes and dimensions to meet different industrial or design needs.

Common Hole Shapes: Round, square, oblong, eyelet, hexagonal, and decorative patterns.

Thickness Range: From 0.1mm to 20mm, depending on usage requirements.

Hole Diameter: Ranges from 0.2mm to 200mm, allowing for precise air flow or filtration.

Standard Sheet Sizes: 1000mm×2000mm, 1220mm×2440mm, or customized sizes are available.

3. Surface Treatment Options

To improve durability and appearance, 304 stainless steel perforated sheets can undergo various surface finishing treatments:

Powder Coating: Enhances corrosion resistance and aesthetic appeal with custom colors.

Spray Painting: Adds rust protection and decorative value.

Polishing: Improves surface smoothness and shine, suitable for applications where appearance matters.

4. Broad Applications Across Industries

Due to its superior properties, the 304 stainless steel perforated sheet finds wide application in many industries:

Architectural Decoration: Used in curtain walls, ceilings, partitions, etc., for both aesthetics and function.

Equipment Protection: Acts as a protective cover for machines, preventing external damage.

Handicraft Manufacturing: Ideal for creating high-end decorative items.

Audio Equipment: Serves as speaker grilles, protecting internal parts without affecting sound quality.

Grain Ventilation & Heat Dissipation: Applied in grain storage and dryers for proper air flow.

Screening & Filtration: Used in mining, chemical, and food industries for separating and purifying materials.

Liquid Filtration: Filters water, oil, and other liquids, ensuring media cleanliness.

Kitchen Equipment: Used in baking trays, drying racks—easy to clean and hygienic.

Road & Factory Safety Fencing: Ensures safety of pedestrians and equipment in public or industrial areas.

5. Conclusion

The 304 stainless steel perforated sheet offers a perfect combination of performance, durability, and design flexibility. Whether you're looking for decorative building materials or reliable industrial components, it provides the ideal solution. As technology evolves, its usage will only become more widespread, making it a material with strong market potential.

For more information or to request custom perforated sheet services, feel free to contact our expert team—we are committed to providing professional solutions tailored to your needs.