Key Specifications to Provide When Customizing Perforated Metal Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-05-29 15:11:36 Browse:

Providing clear and comprehensive information when ordering custom perforated metal sheets is essential to ensure product quality and meet application requirements. Below are the critical elements you should clarify during the customization process:

1. Basic Specification Parameters

Material Type:

Specify the type of metal needed, such as stainless steel, aluminum, copper, or other alloys, depending on strength and corrosion resistance requirements.

Sheet Thickness:

Indicate the thickness of the metal sheet in millimeters or inches, as it affects both strength and processing capabilities.

Dimensions:

Define the length and width of the sheet. If a specific shape is required (e.g., round, rectangular), please provide those details for accurate fabrication and installation.

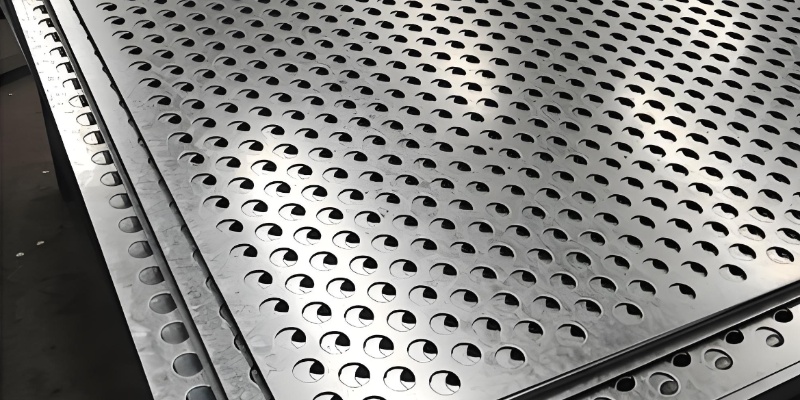

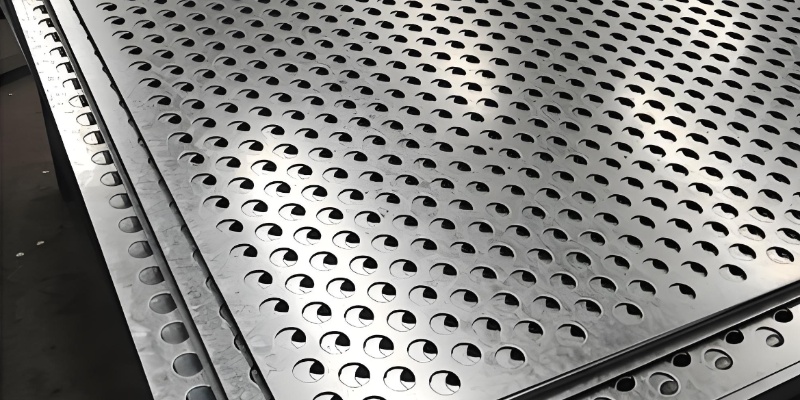

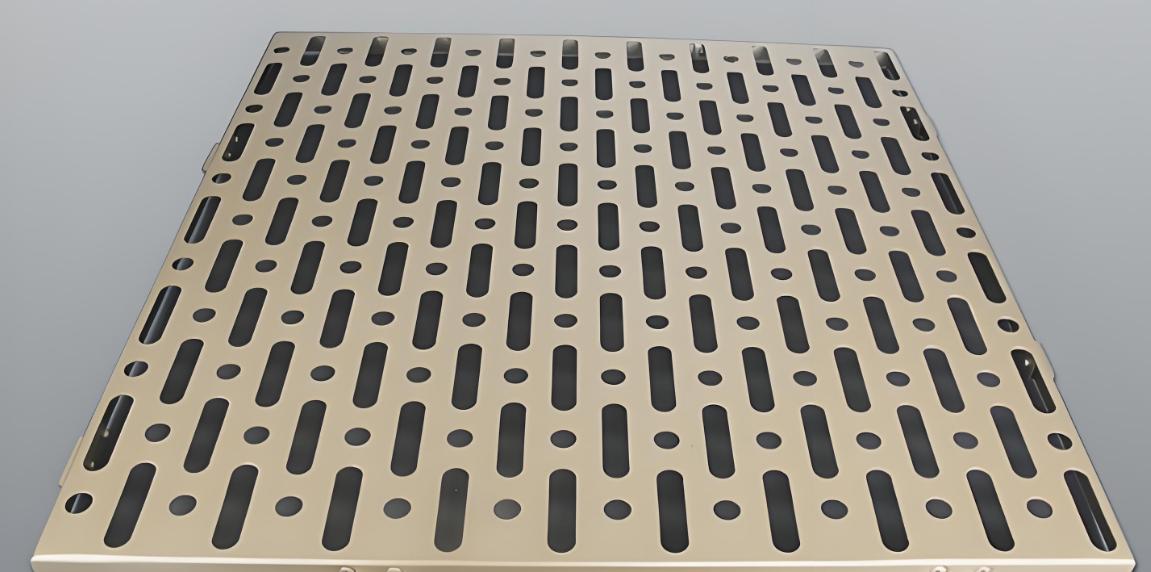

2. Hole Pattern Design

Hole Size:

Specify the diameter or side length of the holes. This directly impacts functions such as ventilation and filtration.

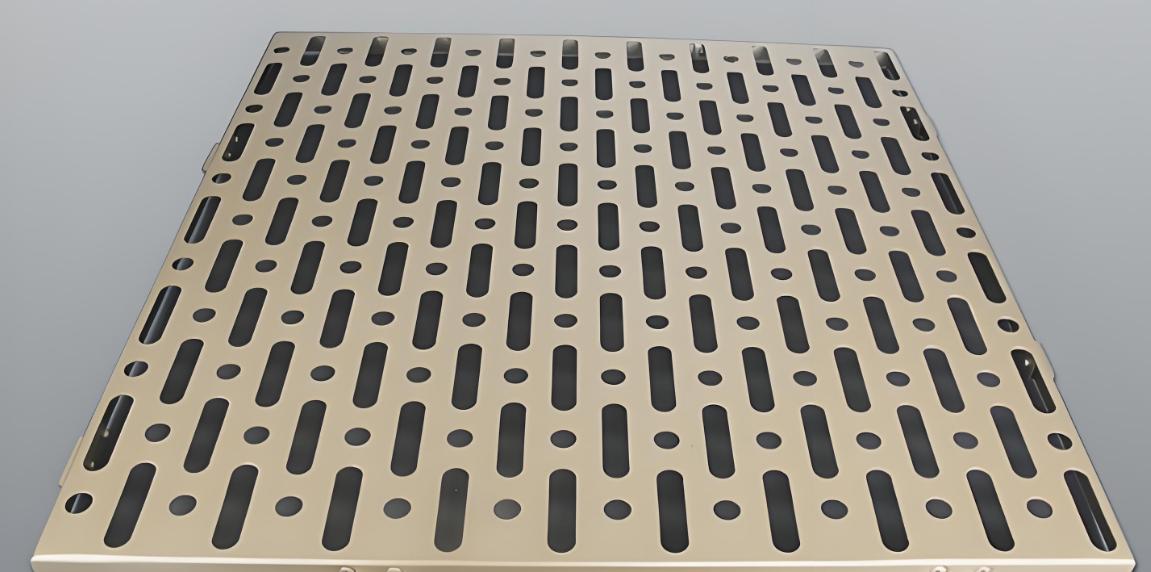

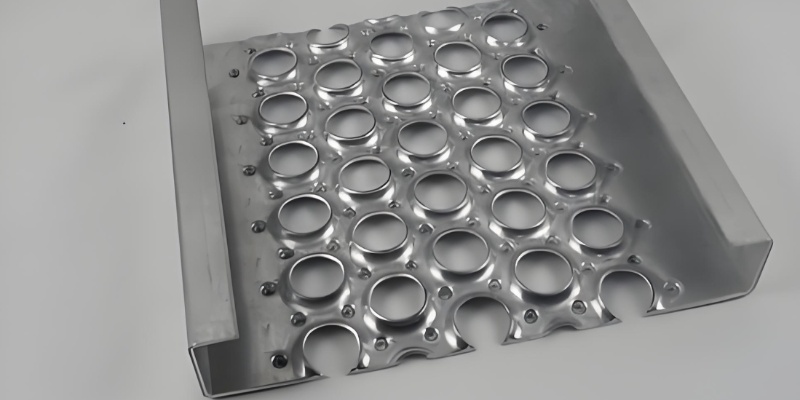

Hole Shape:

Choose the desired hole pattern—round, square, oval, hexagonal, or custom shapes—to meet both functional and aesthetic needs.

Pitch (Center Distance):

Indicate the center-to-center spacing between holes. This affects the sheet’s strength and open area ratio.

3. Surface Treatment

Processing Method:

Select a suitable surface treatment method such as polishing, brushing, sandblasting, or electroplating based on the application environment. This enhances appearance and durability.

Color Requirements:

If a specific color or coating is needed, please specify to ensure the final product aligns with your design expectations.

4. Functional Requirements

Application Scenario:

Describe the intended use of the perforated sheet—architectural cladding, noise barrier, filtration unit, etc.—so the manufacturer can better understand the performance requirements.

Performance Standards:

If you have specific expectations such as corrosion resistance, load-bearing capacity, or fire resistance, please state them clearly to ensure compliance.

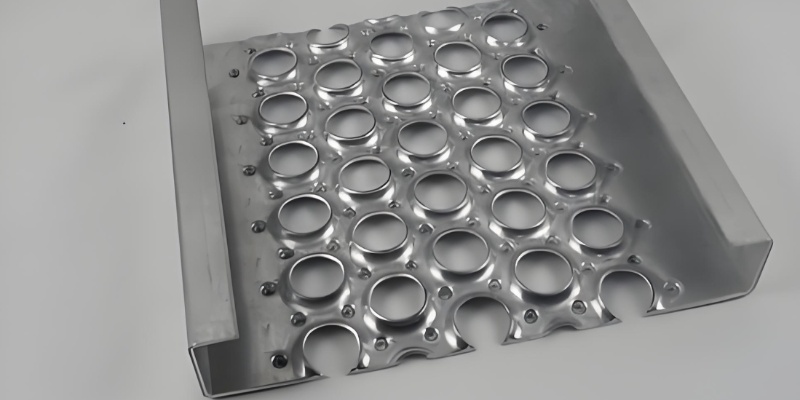

5. Processing and Installation Details

Edge Treatment:

Specify whether the edges need chamfering, bending, or other processing to improve safety and aesthetics.

Mounting Method:

Provide details on how the sheet will be installed—bolt holes, welding points, etc.—to facilitate efficient and secure installation.

6. Quantity and Delivery Time

Order Volume:

Indicate the quantity required to help the manufacturer manage production scheduling effectively.

Delivery Deadline:

Mention your preferred delivery date to ensure your project timeline stays on track.

7. Additional Considerations

Drawings or Samples:

If you have existing technical drawings or reference samples, please share them to ensure the manufacturer fully understands your requirements.

Quality Standards:

If the product must comply with specific industry standards or certifications (e.g., ISO, ASTM), please let the supplier know in advance.

By providing the above detailed information, you help ensure that the perforated metal sheet produced meets your expectations precisely. If you have any questions or uncertainties, feel free to contact us. Our professional team is ready to assist you with tailored solutions.