Broad Applications of Stainless Steel Perforated Sheets

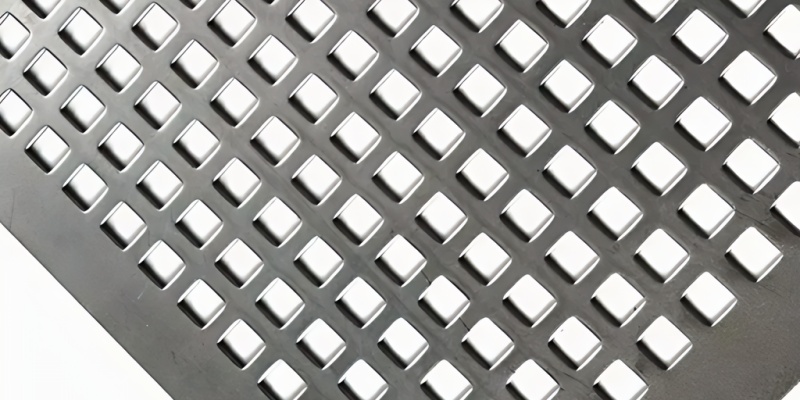

Architecture and Decoration

Stainless steel perforated sheets are widely used in modern architecture, including curtain walls, ceilings, and stair railings. They not only provide ventilation and natural lighting but also enhance the aesthetic appeal of buildings.

Industrial Equipment Protection

In mechanical and industrial environments, perforated metal sheets act as protective covers and safety guards. They effectively shield personnel from direct contact with moving parts and contribute to a safer working environment.

Acoustic Equipment Manufacturing

Thanks to their favorable acoustic properties, stainless steel perforated sheets are commonly used in speaker grills and audio equipment casings. They protect internal components without compromising sound quality.

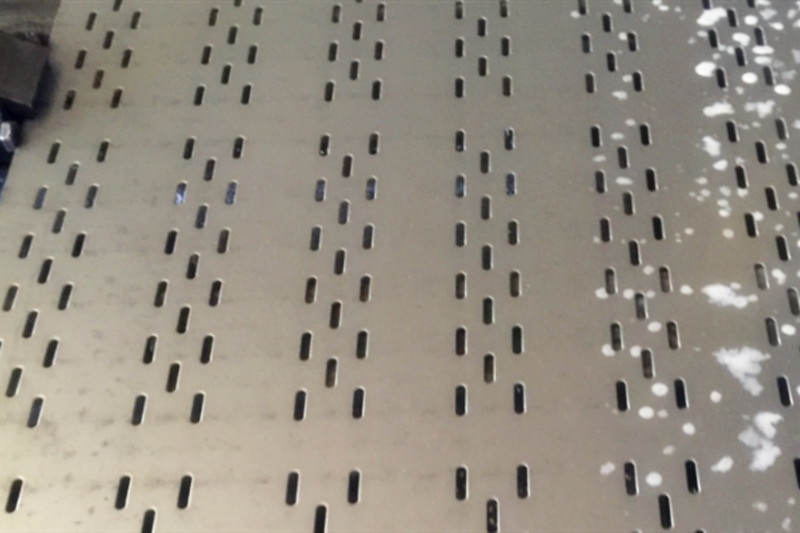

Agriculture and Grain Storage

In agricultural settings, perforated metal sheets are essential in grain silos and ventilation systems. They help maintain dryness, prevent mold, and preserve grain quality.

Mining, Chemical Processing, and Food Production

Stainless steel perforated sheets play a key role in ore screening, chemical filtration, and food classification. Their corrosion resistance and hygienic surface meet the stringent standards of these industries.

Kitchen Equipment and Utensil Manufacturing

Due to their cleanability and corrosion resistance, stainless steel perforated sheets are ideal for kitchen tools, such as filters, steamers, and baking trays.

Infrastructure and Transportation

These sheets are commonly seen in road barriers, bridge protection systems, and subway ventilation projects, offering structural support and enhanced safety. Their modern design also improves overall visual impact.

Conclusion

With diverse functions and outstanding performance, stainless steel perforated sheets are indispensable across various sectors. Whether enhancing a building’s visual appeal or meeting industrial-grade durability requirements, they deliver reliable and efficient solutions.

Choosing the right stainless steel perforated sheet can increase your project's efficiency and longevity. For detailed product information and application examples, please visit Hebei Senchi's official website at www.cn-psp.cn.