4. Hole Patterns & Decorative Options

We offer a wide range of hole shapes to suit functional and aesthetic needs:

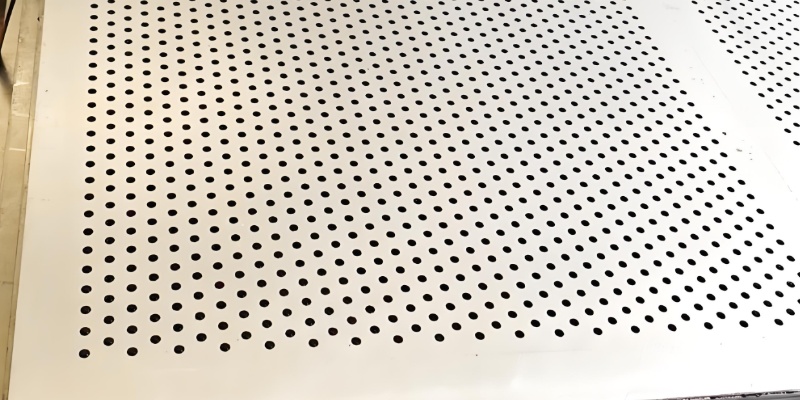

Round Holes (most common, universal use)

Square Holes (modern look, suitable for decoration and protection)

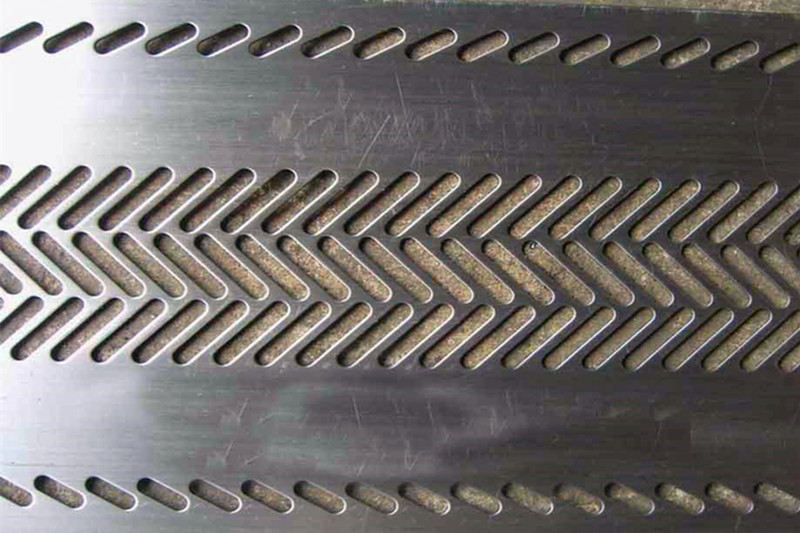

Slotted or Oblong Holes (for ventilation and drainage)

Slot Holes (for mechanical matching)

Crocodile Mouth, Fish Eye Holes (ideal for anti-slip applications)

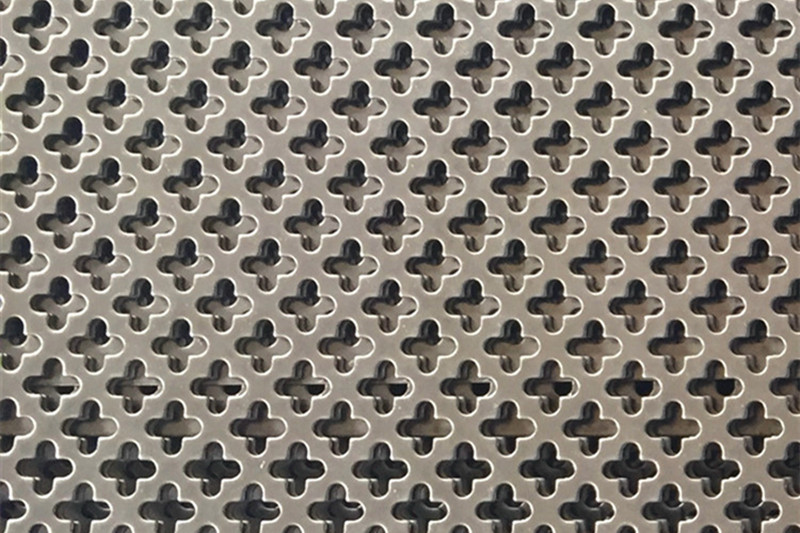

Pentagonal, Hexagonal, Irregular Holes (for creative designs)

Custom Patterns or Logos (laser-cut designs based on your CAD files)

These variations provide both technical utility and decorative enhancement, meeting the needs of modern industrial and design applications.

5. Surface Finishing & Performance

Surface treatments are available to enhance appearance, durability, and resistance:

Polishing: For mirror-finish decorative use.

Brushing: Satin surface ideal for architectural interiors.

Powder Coating or Spray Painting: Offers added corrosion resistance and color options.

Electroplating: Enhances conductivity and surface hardness.

These finishes extend product lifespan and make stainless steel perforated sheets visually appealing for high-end applications.

6. Wide Range of Applications

Stainless steel perforated sheets serve in a broad spectrum of fields:

Architecture: Curtain walls, ceilings, partitions, stair treads, balconies, sunshades

Machinery: Equipment enclosures, protective guards, heat dissipation panels

Environmental Protection: Filtration screens for water treatment, ducts, and ventilation systems

Food Industry: Sanitary-grade screening and filtering plates

Transportation: Ceilings and panels in metro stations, airports, rail terminals

Security & Safety: Anti-theft doors, machine guards, safety barriers

Whether functional or decorative, perforated metal sheets elevate both performance and design.

7. Manufacturing Strength & Service Commitment

As a professional manufacturer specializing in stainless steel perforated sheet production, we provide:

Advanced CNC punching systems for accurate, efficient production

Strict quality inspection procedures throughout each process

Comprehensive customization capabilities, from small samples to large-scale production

Fast response and flexible delivery, tailored to meet your project timelines

No matter your industry, we offer stable supply, professional advice, and dependable product performance.

8. Conclusion: Optimize Your Project with the Right Perforated Metal Sheet

Stainless steel perforated sheets are indispensable in modern architecture, industry, and infrastructure. Their strength, flexibility, and visual appeal offer significant benefits in filtration, decoration, ventilation, and safety.

By selecting the appropriate thickness, hole type, layout, and finish, you ensure both the functional efficiency and aesthetic value of your application. Whether you're an architect, contractor, or machinery manufacturer, our tailored perforated sheet solutions are ready to support your success.

Contact us today for quotations, sample requests, or custom design consultations. Our expert team is here to deliver the right perforated metal solution for your needs.