Introduction to Safety Grating – The Ideal Anti-Slip Solution for Industrial and Public Safety

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-14 11:35:41 Browse:

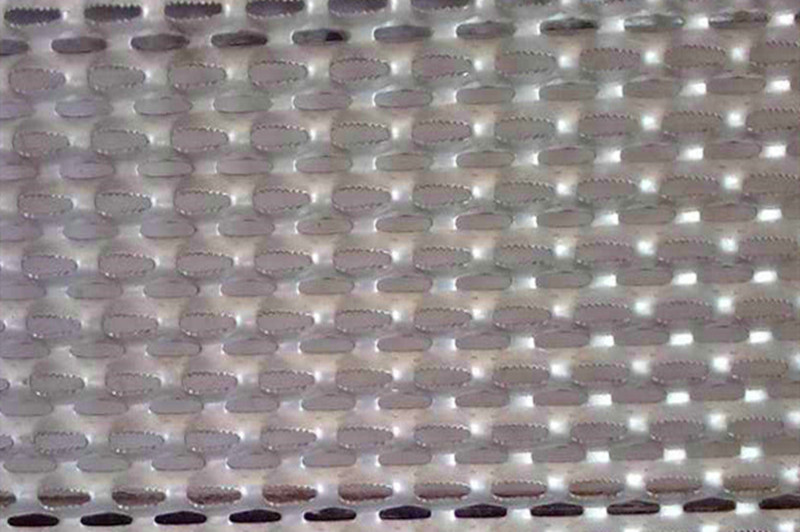

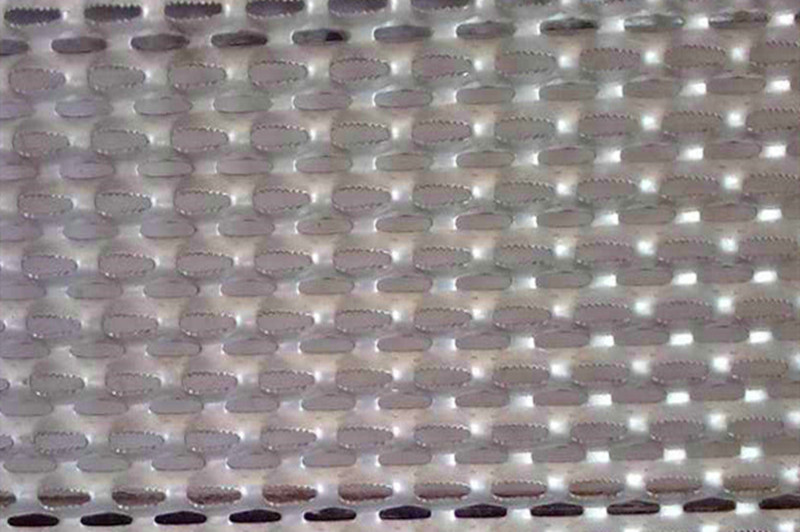

In modern industrial environments and public safety infrastructure, anti-slip measures have become a crucial component. Safety grating, also known as “crocodile mouth perforated plate” or “anti-slip perforated metal sheet,” is widely recognized for its superior slip resistance, aesthetic appeal, and broad application scenarios. It is the preferred safety material for many industrial and construction projects.

1. Raw Materials and Specifications of Safety Grating

Safety grating is manufactured using a variety of high-performance metal sheets, including:

Mild steel: Ideal for standard environments, cost-effective;

Stainless steel: Offers excellent corrosion resistance for wet or chemical-prone conditions;

Aluminum: Lightweight and corrosion-resistant, suitable for applications requiring reduced structural weight.

The typical plate thickness ranges from 1mm to 4mm, with customization available based on specific project requirements. The hole size and pattern can also be tailored according to actual usage needs, providing maximum flexibility.

2. Manufacturing Process of Safety Grating

Each piece of safety grating undergoes a meticulous manufacturing process to ensure durability and functionality:

CNC Punching: Precisely formed holes enhance anti-slip performance;

Shearing and Bending: Shapes the grating for its intended environment;

Welding and Forming: Ensures structural stability and consistent quality;

Surface Finishing:

Mild steel grating typically receives hot-dip galvanizing to prevent rust;

Stainless steel and aluminum surfaces can remain natural or be polished for improved durability and appearance.

Common perforation shapes include raised herringbone, cross-flower patterns, and circular holes. These designs not only improve traction but also enhance visual appeal.

Safety grating

3. Key Features of Safety Grating

Excellent Slip Resistance: Specialized punched patterns and raised structures reduce the risk of slips, especially in environments with moisture, oil, snow, or vibration;

Corrosion and Rust Resistance: Surface treatments enable use in harsh or extreme climates;

High Durability and Load Capacity: Designed to withstand pressure without deformation over long-term use;

Easy Installation and Maintenance: Lightweight for transport and simple to install, with low upkeep costs;

Visually Appealing: Diverse perforation styles and finish options make it both functional and decorative.

Safety grating

4. Applications of Safety Grating

Thanks to its versatile properties, safety grating is widely used across a broad spectrum of industries and facilities:

Industrial Sites: Such as wastewater treatment plants, waterworks, power plants, and chemical factories—for walkways, inspection platforms, and operating stations;

Transport Infrastructure: Including subways, trains, and public bus stations—for stair treads, ramps, and anti-slip walkways;

Mechanical Equipment: Applied as machine platforms and footboards to enhance operational safety;

Construction Projects: Temporary pedestrian paths, overhead platforms, and scaffolding safety;

Interior Design and Renovation: Increasingly used in underground garages, exhibition halls, and commercial walkways for both safety and aesthetic purposes.

In particularly challenging environments—such as oily surfaces, icy roads, or vibrating workspaces—safety grating plays a vital role in preventing accidents and ensuring smooth workflow.

Safety grating

5. Practical Value of Safety Grating

With rising demands for safety and efficiency in industrial and commercial operations, safety grating is more than just an anti-slip surface—it’s a critical component of modern infrastructure. It significantly reduces the risk of workplace accidents, boosts productivity, and lowers the cost of injury-related downtime. Its long lifespan and low maintenance also make it a highly economical safety investment.

Conclusion:

Safety grating is a metal solution that combines functionality, durability, and visual appeal. With wide-ranging uses and reliable performance, it provides essential protection for both industrial facilities and public infrastructure. Whether you are upgrading safety standards or starting a new project, choosing the right safety grating is a smart and effective decision.

For more information about product specifications, custom solutions, or purchasing options, feel free to contact us. Our team is ready to provide you with professional advice and high-quality service.