What Are the Perforation Methods of Perforated Sheet? A Detailed Overview of Processing Techniques and Applications

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-14 11:39:46 Browse:

Perforated sheet refers to a type of metal or non-metal plate processed with regularly or irregularly shaped holes to meet various functional and decorative needs. These sheets are widely used across construction, industrial manufacturing, urban infrastructure, and environmental noise control systems. This article explores in detail the definition of perforated sheet, common hole types, perforation methods, and typical use cases.

What Is a Perforated Sheet?

A perforated sheet, also known as perforated plate, punched sheet, or multi-hole sheet, is manufactured by punching or laser cutting holes into a base material. These sheets provide excellent air and light permeability, strength, and aesthetic value, making them versatile for both functional and decorative purposes.

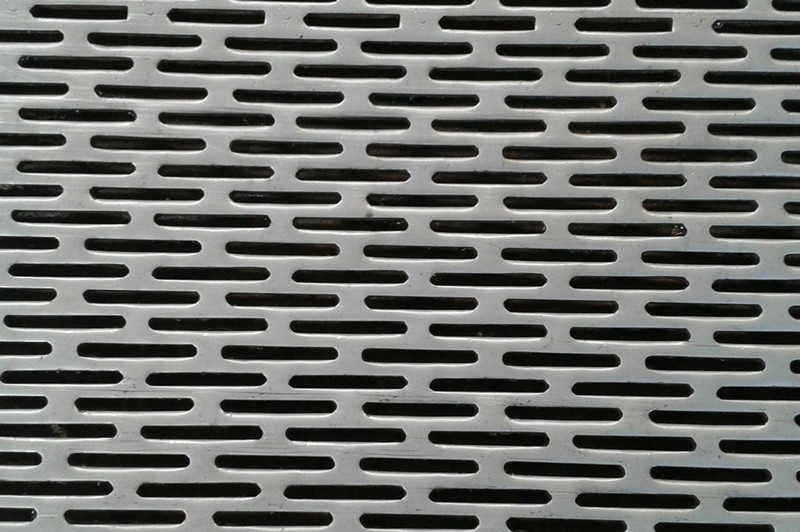

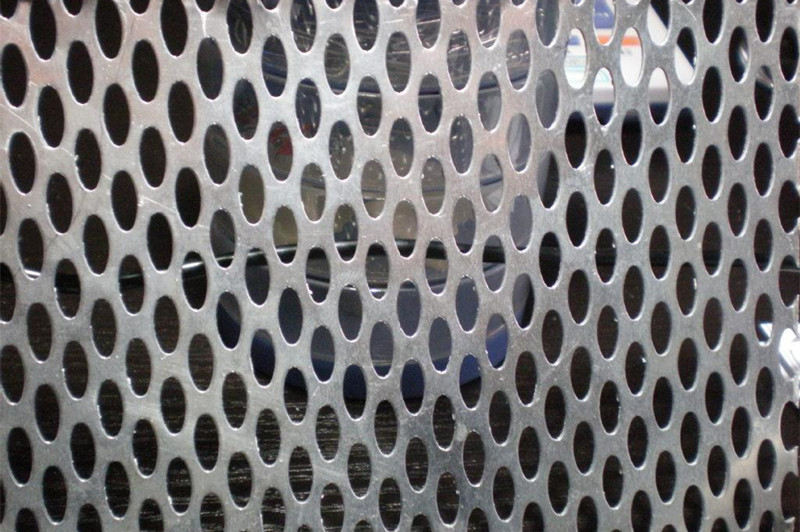

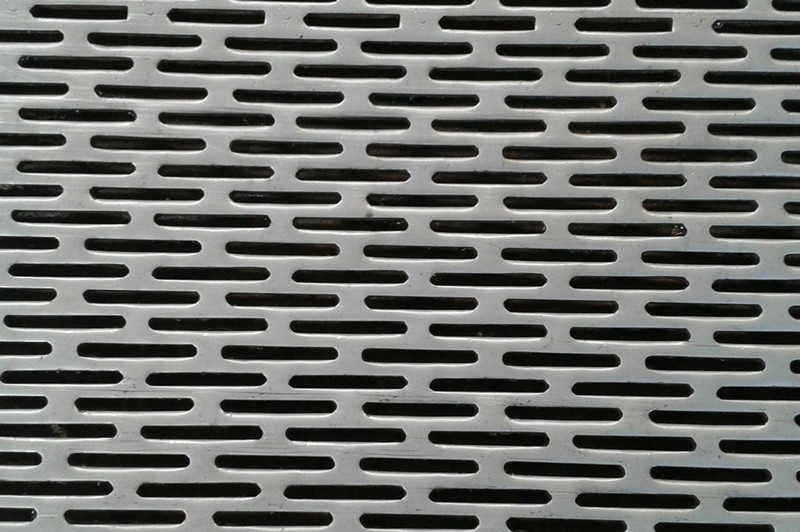

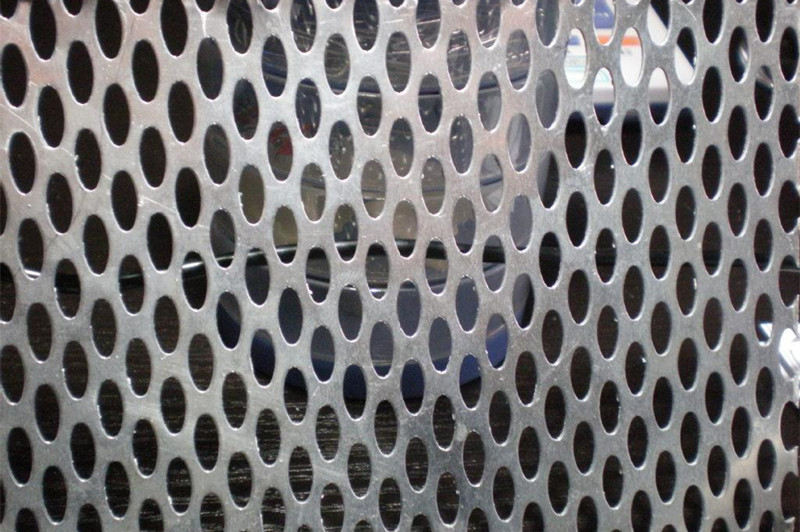

Perforated sheet

Common Materials:

Stainless steel (corrosion-resistant and strong)

Low-carbon steel (cost-effective and easy to process)

Galvanized sheet (offers rust protection)

Cold-rolled coils (smooth surface and formable)

PVC composite sheets (lightweight and durable)

Typical Sizes:

Coil: 1m × 20m

Flat sheet: 1m × 2m

Custom sizes available upon request

Types of Hole Shapes

The hole pattern in a perforated sheet directly influences its function and visual effect. Below are common types of hole designs:

Round holes – Ideal for ventilation, filtration

Long round holes – Also called oblong holes; suitable for drainage or cable routing

Square and rectangular holes – Frequently used for aesthetic or cooling purposes

Hexagonal holes – Honeycomb structure for strength and airflow

Triangular, plum blossom, star-shaped holes – Typically used for decorative panels

Fish scale, peony, and custom-shaped holes – For unique design appeal

Raised or embossed holes – Used for anti-slip surfaces and reinforcement

Perforated sheet

Perforation Methods Explained

Different perforation methods affect both the efficiency and precision of the final product. Here are the main punching techniques used in perforated sheet manufacturing:

Continuous Punching in the Same Direction

This method uses rectangular dies in overlapping motions to create elongated holes or trim edges. It is efficient and widely applied.

Continuous Forming

Used to produce features larger than the die itself—such as louvers, reinforcing ribs, or tread steps.

Nibbling

A small round punch is used at short intervals to create arc-shaped sections or complex outlines.

Multi-Directional Continuous Punching

Small dies are used to gradually form large holes or intricate shapes from various directions.

Single-Forming Punch

A single shallow draw operation forms a component based on the mold’s shape, often used for embossed designs.

Single Punching

Performs one-time punching, suited for linear, circular, circumferential, or grid arrangements.

Array Forming

Produces multiple identical or diverse punched parts on a large base plate, improving batch processing efficiency.

Perforated sheet

Common Applications of Perforated Sheet

Thanks to its strength, breathability, and design flexibility, perforated sheet metal is used across multiple industries and environments:

Architecture and Decoration: Stair treads, balcony railings, ceilings, wall panels, sunshades

Municipal Infrastructure: Noise barriers for highways, subways, and urban rail systems

Environmental Protection: Sound-absorbing panels in factories, generator rooms, and workshops

Mechanical Protection: Ventilation covers, safety guards, equipment shielding

Agriculture & Grain Handling: Storage silo screens, grain sieves, feed screens

Kitchen Equipment: Stainless steel baskets, food covers, fruit trays, commercial kitchen use

Retail & Displays: Store shelving, display stands, product holders

Electronics Industry: Dustproof and soundproof enclosures for speakers and devices

Conclusion

Perforated sheet metal is a highly adaptable material that serves both functional and aesthetic purposes across a wide range of industries. With advancements in punching and forming techniques, its applications continue to expand. Selecting the right hole pattern and processing method can greatly enhance both the performance and appearance of your project.

If you are looking for high-quality perforated sheet products or need customized solutions tailored to your specifications, feel free to contact us. We provide professional support and reliable products to meet your unique needs.