What Is the Normal Tolerance Range for Stainless Steel Perforated Sheet?

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-10 21:55:51 Browse:

Stainless steel perforated sheet is a versatile metal product widely used in architectural design, industrial filtration, acoustic insulation, anti-slip panels, and more. The quality and performance of perforated sheets largely depend on manufacturing precision. This article explains the normal tolerance range for stainless steel perforated sheets in terms of hole diameter, pitch, and overall dimensions—crucial information for engineers, contractors, and buyers in the construction, filtration, and decorative industries.

1. Hole Diameter Tolerance: Precision Drives Performance

Hole diameter is a key factor that directly affects the performance of a stainless steel perforated sheet, especially in filtration and ventilation systems. Typically produced using CNC punching machines, these sheets can achieve high precision and consistency.

Under standard production conditions, the hole diameter tolerance should be controlled within ±0.05mm. This level of accuracy meets the needs of most applications, including building facades, ceilings, partition panels, and filtration systems. For ultra-precise requirements—such as microfiltration in liquid or gas systems—laser perforation is recommended.

2. Hole Spacing Tolerance: Ensuring Visual and Structural Integrity

Hole spacing (or pitch) determines the alignment and distribution of perforations across the sheet. It plays a critical role in the structural strength and visual appearance of the product. Misaligned holes can disrupt aesthetics or make installation difficult.

A high-quality stainless steel perforated sheet should maintain a hole spacing tolerance within ±0.05mm. This ensures consistent patterns and even spacing—especially important in decorative architectural uses like cladding systems, railings, and interior panels.

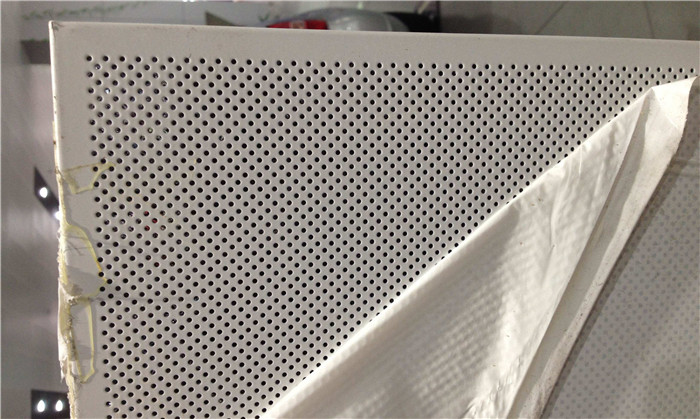

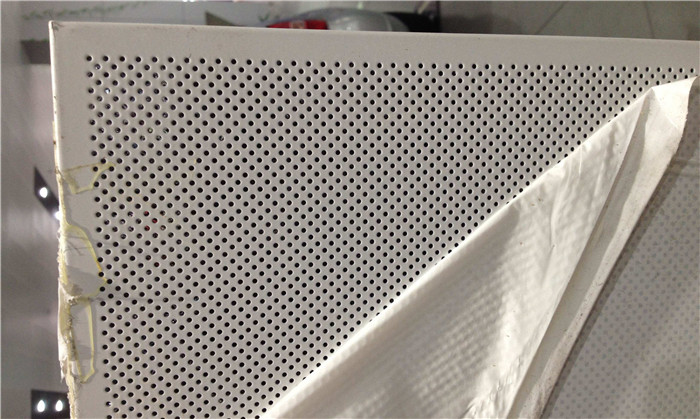

Stainless steel Perforated sheet

3. Sheet Dimension Tolerance: Varies by Application

The overall length and width of a perforated sheet are also key quality indicators. Standard cutting processes such as shearing or die cutting generally allow for a dimension tolerance of ±3mm, which is acceptable for most structural or decorative installations.

For high-precision applications—such as embedded mounting, frame fit, or laser-aligned assemblies—laser cutting is strongly recommended. It can reduce dimension tolerance to ±0.5mm, ensuring a perfect fit.

4. Tolerance Requirements by Application

Construction Industry: For facade systems, staircases, and ceilings, consistent hole spacing and accurate dimensions are essential for alignment and stability.

Filtration Industry: Hole diameter is critical, as any deviation may impact filtering efficiency and system reliability.

Decorative Industry: Symmetry and aesthetic quality matter most, making precise spacing and clean edges vital.

5. Final Thoughts: Precision Manufacturing Ensures Quality

Achieving a high-quality stainless steel perforated sheet depends on advanced manufacturing techniques and strict quality control. Understanding the acceptable tolerance range for hole diameter, spacing, and dimensions helps customers make informed purchasing decisions and highlights the professionalism of the supplier.

Our company uses advanced CNC punching and laser cutting systems to deliver perforated metal solutions that meet various specifications. Whether you require standard sizes or custom cuts, we ensure precision, consistency, and premium surface finishes. Contact us for free samples or technical consultation.