What is the Difference Between High-Quality and Inferior Stainless Steel Plates in Stainless Steel Perforated Sheet Production?

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-14 14:55:12 Browse:

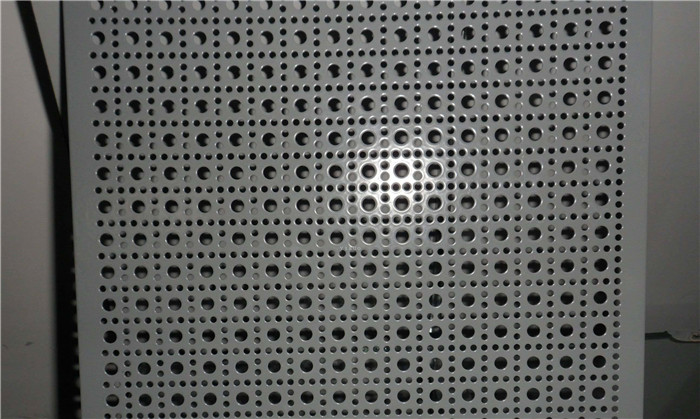

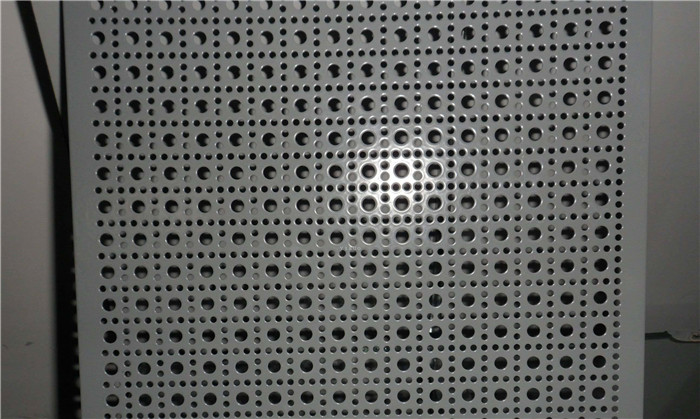

Stainless steel perforated sheet is a mesh product manufactured by continuous punching on a precision CNC punching machine using stainless steel sheets, according to specific molds. Due to the market's sensitivity to price, some unscrupulous businesses use inferior stainless steel sheets as raw materials to produce stainless steel perforated sheets, deceiving customers. In this article, we will detail the differences between using high-quality stainless steel sheets and inferior stainless steel sheets as raw materials for stainless steel perforated sheet production, to help identify the quality of stainless steel perforated sheets.

1. Visual Inspection

Stainless steel perforated sheets made from inferior stainless steel sheets will have broken edges on the perforations. This is especially noticeable in perforated mesh products with intricate hole shapes such as leaf-shaped holes, crocodile mouth shapes, round raised shapes, etc. Inferior stainless steel sheets have lower precision during processing, leading to irregular hole shapes and rough edges, which not only affect the appearance but also impact the functionality of the product.

2. Surface Quality Inspection

Check the surface of the stainless steel perforated sheet for defects such as oxide scale, cracks, rust stains, or scratches. High-quality stainless steel plates have smooth and clean surfaces without significant defects, while inferior stainless steel sheets often show surface imperfections during production. If oxide scale or rust stains appear outside the perforated area, it is a clear indicator that the stainless steel perforated sheet was made from substandard stainless steel sheets. Furthermore, inferior stainless steel sheets are more susceptible to corrosion, which can reduce the product's lifespan and safety.

Stainless steel Perforated sheet

3. Chemical Solution Test

A chemical solution test can effectively differentiate between different types of stainless steel. Various stainless steel types will react with the solution, producing different color changes. High-quality stainless steel sheets will exhibit stable and consistent reactions, whereas inferior stainless steel sheets, due to uneven composition, may show unusual color changes. This testing method provides a scientific way to confirm the material quality of stainless steel sheets and avoid the use of inferior raw materials.

4. Corrosion Resistance Test

Corrosion resistance is a crucial criterion for evaluating stainless steel materials. High-quality stainless steel sheets possess excellent oxidation resistance and corrosion resistance, ensuring long-term stability even in harsh environments. Inferior stainless steel sheets, however, are prone to corrosion when exposed to chemicals, leading to rusting or discoloration, and potentially affecting structural strength. When selecting stainless steel perforated sheets, checking their corrosion resistance is a key step in determining their quality.

5. Service Life and Maintenance Costs

High-quality stainless steel perforated sheets generally offer a longer service life and lower maintenance costs. Inferior stainless steel perforated sheets may suffer from corrosion, deformation, and other issues after prolonged use, leading to higher maintenance and replacement frequencies, thus increasing long-term costs. Therefore, when choosing stainless steel perforated sheets, it’s essential to assess not only the initial cost but also the expected service life and maintenance costs.

Conclusion

Using high-quality stainless steel sheets as raw materials for producing stainless steel perforated sheets ensures excellent appearance, superior performance, and an extended service life with greater corrosion resistance. Consumers should utilize visual inspection, surface quality checks, chemical testing, and other methods to identify the quality of stainless steel perforated sheets to avoid being deceived by low-cost, inferior products.

We hope this article helps you better understand how to identify the quality of stainless steel perforated sheets and choose the right products. If you have any questions, feel free to contact us for expert technical support and high-quality products.