Why Does Stainless Steel Perforated Sheet Rust? A Detailed Explanation and Prevention Guide

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-14 15:00:01 Browse:

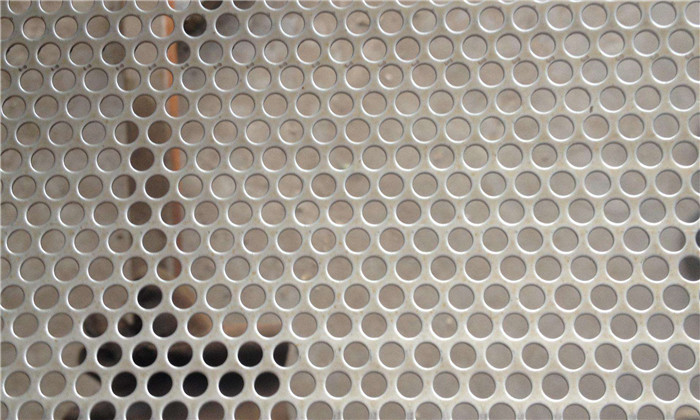

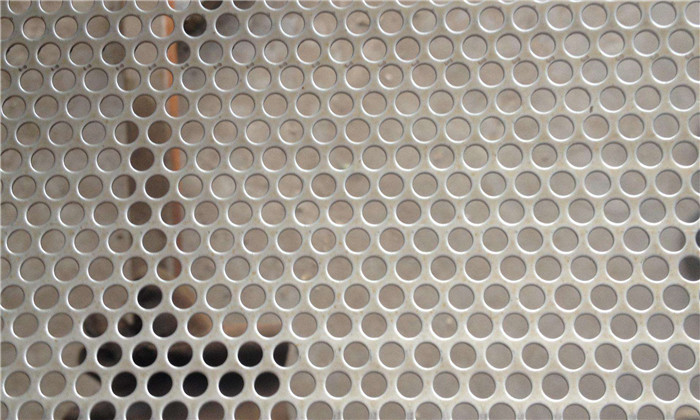

Stainless steel perforated sheet is a high-performance metal mesh material widely used in architectural decoration, mechanical protection, ventilation, noise reduction, and more. Made from premium stainless steel plates through precision CNC punching, it features excellent corrosion resistance, high-temperature tolerance, and mechanical strength, making it a preferred material in many applications.

However, in real-world use, many users are surprised to find that stainless steel perforated sheets can still rust under certain conditions. So why does this happen? Is it due to material defects or improper usage? This article provides a comprehensive look at the causes of rust on stainless steel perforated sheets and offers practical tips to prevent it.

1. The Corrosion Resistance Mechanism of Stainless Steel Perforated Sheets

The rust-resistant nature of stainless steel lies in its ability to form a thin, dense, and stable chromium oxide film on the surface. This protective layer blocks moisture and oxygen from penetrating deeper, thus preventing oxidation.

However, this passive film is not completely invulnerable. Once damaged and not promptly restored, corrosion can begin at the exposed areas, leading to localized rusting.

2. Key Factors Affecting Corrosion Resistance

1. Stainless Steel Grade

The corrosion resistance varies significantly by material grade:

304 stainless steel: Performs well in dry indoor environments but may rust quickly in coastal or high-salinity areas.

316 stainless steel: Contains molybdenum and offers better resistance in acidic, humid, or salt-laden conditions—ideal for marine or chemical environments.

2. Environmental Conditions

The chemical properties of the surrounding environment greatly influence corrosion behavior:

High humidity or poor ventilation;

Salty or acidic air (e.g., seaside or industrial areas);

Exposure to corrosive liquids or vapors.

3. Manufacturing and Surface Treatment

Residual weld spatter, scratches, or embedded metal particles from processing can trigger corrosion if not removed properly. Surfaces that haven't been treated with acid pickling or passivation are also more prone to rusting.

3. Common Causes of Rust on Stainless Steel Perforated Sheets

1. Electrochemical Corrosion

When foreign metal particles (e.g., iron filings or copper dust) adhere to the stainless steel surface and the environment is humid, micro-galvanic cells can form. This electrochemical reaction disrupts the passive layer, causing rust. This often happens after renovations when debris from metal tools accumulates in sinks, creating "floating rust."

2. Organic Acid Corrosion

Residue from food, fruit juice, sauces, or soup on the perforated sheet can ferment or break down into organic acids. Over time, these acids may corrode the stainless steel surface, especially in warm and moist environments.

3. Acid and Alkaline Corrosion

During construction, substances like limewater, cement splashes, or alkali can stick to the surface. If not cleaned immediately, these substances can damage the passive film and cause pitting. For example, failing to dry a sink after use may lead to rust due to residual water and cleaning agents.

4. Atmospheric Chemical Corrosion

In areas with air pollution, especially where sulfur dioxide, carbon dioxide, or nitrogen oxides are present, condensation may form acidic droplets (e.g., sulfuric, nitric, or acetic acid). These acids can leave corrosion marks on the surface.

Stainless steel Perforated sheet

4. How to Prevent Rust on Stainless Steel Perforated Sheets

1. Choose the Right Material

Selecting the appropriate stainless steel grade is crucial:

For dry indoor use: 304 is sufficient;

For outdoor, coastal, or chemical environments: use 316 or higher-grade stainless steel for better protection.

2. Regular Cleaning and Maintenance

Clean the surface of the stainless steel perforated sheet regularly with water or neutral detergent. This is especially important after rainy days or during construction, as frequent cleaning helps prevent buildup of corrosive particles.

3. Avoid Exposure to Corrosive Agents

During installation and use, avoid contact with lime, bleach, iron particles, seawater, and similar corrosive substances. Construction workers should be instructed to handle materials carefully and clean surfaces thoroughly after use.

4. Surface Protection Treatments

For perforated sheets exposed to harsh environments, consider treatments such as passivation, protective coatings, or applying surface films to enhance their corrosion resistance.

5. Conclusion: Smart Usage Extends Service Life

Although stainless steel perforated sheets are known for their corrosion resistance, they are not completely immune to rust. Durability largely depends on correct material selection, usage conditions, and maintenance routines. By following the best practices above, users can fully leverage the advantages of stainless steel perforated sheets and extend their lifespan significantly.

Looking for high-quality stainless steel perforated sheet products with strong corrosion resistance? Contact us today—we offer internationally certified materials, multiple grades, and customized solutions tailored to your specific environment and needs.