Detailed Explanation of Stainless Steel Perforated Sheet Leveling Method

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-14 15:02:21 Browse:

During the production of stainless steel perforated sheets, severe mechanical stress is often generated due to the punching process. This frequently causes the sheets to become warped or curled. If these deformations are not properly leveled, they can significantly affect the quality of the finished product and hinder subsequent processing. Therefore, implementing an effective leveling method is a critical step in the manufacturing of stainless steel perforated sheets.

Why Leveling Is Necessary for Stainless Steel Perforated Sheets

The punching process introduces uneven stress across the surface and inside the stainless steel perforated sheet. As a result, the sheet can exhibit warping, edge curling, or uneven surfaces. If left untreated, these deformities can interfere with accurate positioning during cutting, bending, or welding, and even reduce the structural integrity and appearance of the final product.

Leveling is essential to restore the sheet to a flat state, releasing internal stress and ensuring the sheet is suitable for further fabrication. A properly leveled stainless steel perforated sheet enhances processing efficiency and guarantees superior product performance.

Common Leveling Equipment: Multi-Roll Leveling Machine

The most widely used equipment for stainless steel perforated sheet leveling is the multi-roll leveling machine. This machine features multiple sets of closely spaced rollers arranged in upper and lower rows. As the sheet passes between these rollers, it undergoes gradual plastic deformation, which reduces internal stress and corrects surface flatness.

How the Multi-Roll Leveling Machine Works

Gradual Flattening: The multi-roll design allows the sheet to be leveled in stages without damaging the surface.

Adjustable Pressure: Operators can finely adjust the roller pressure and spacing according to the thickness, perforation density, and deformation level of the sheet.

Multiple Passes for Severe Deformation: Severely deformed sheets may require multiple leveling passes. Each pass further alleviates deformation, eventually achieving the desired flatness.

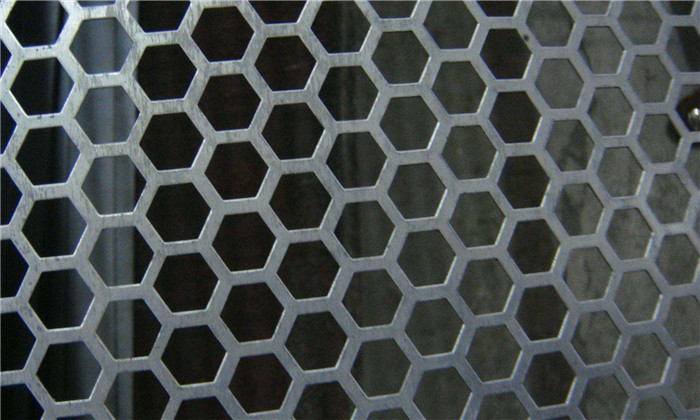

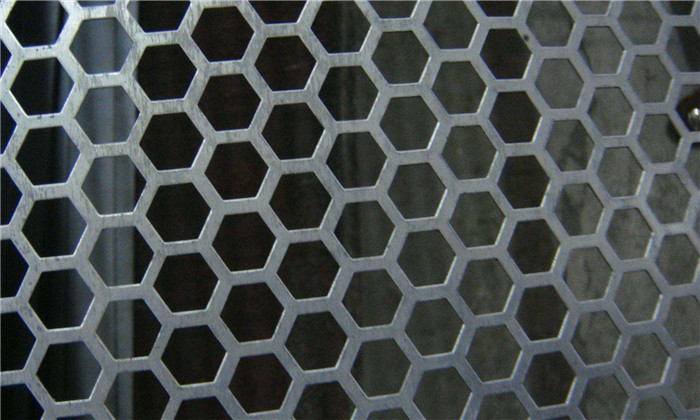

Stainless steel Perforated sheet

Leveling Methods Based on Deformation Severity

For Slightly Deformed Sheets

If the stainless steel perforated sheet has only minor warping, a single pass through the leveling machine is usually sufficient. By properly adjusting roller pressure, the sheet can be returned to a relatively flat state without additional processing.

For Moderately to Severely Deformed Sheets

When deformation is more pronounced, a more refined leveling method is necessary. The sheet should be passed through the machine multiple times, with roller pressure adjusted each time based on the remaining deformation. Technicians should observe the flattening effect during each pass and gradually reduce warping until the required flatness is achieved.

Key Factors for Ensuring Leveling Quality

To ensure the quality of the leveled stainless steel perforated sheet, the following points should be considered during the process:

Preheating: In low-temperature environments, preheating the sheet can help reduce stress concentration and improve leveling efficiency.

Clean Rollers: The rollers should remain clean and smooth to prevent scratches on the sheet surface.

Controlled Speed: The feeding speed must be well-managed. Excessive speed can lead to incomplete leveling, while very slow speeds may reduce efficiency.

Sheet Thickness Handling: Sheets of different thicknesses or perforation densities should be leveled separately to ensure uniform results.

Conclusion

During the manufacturing of stainless steel perforated sheets, the leveling process plays a vital role in correcting deformation caused by punching operations. By using a multi-roll leveling machine with proper pressure adjustments and controlled feeding, manufacturers can effectively restore sheet flatness. Mastering the leveling method not only ensures the quality of the finished product but also enhances overall production efficiency and reliability.