Before providing an accurate quotation to customers, it's crucial to understand all the cost components involved. This article analyzes the pricing factors of stainless steel perforated sheets from multiple angles including materials, processing, and specifications.

1. Material Grade and Alloy Composition

Common stainless steel grades used in perforated sheets include 201, 304, and 316. Due to significant differences in alloy content such as nickel and chromium, each grade varies in performance and cost.

Grade 201 is the most cost-effective due to its lower alloy content and moderate corrosion resistance.

Grade 304 offers a balanced price-performance ratio with excellent oxidation resistance.

Grade 316 provides superior resistance in acidic or alkaline environments due to the addition of molybdenum, which raises the unit price.

Specialty grades like duplex stainless steel (2205) or high-temperature alloys (310S) also command higher raw material costs, significantly affecting the final price.

2. Raw Material Market Fluctuations

Since perforated sheets are primarily made from stainless steel coils, any fluctuation in the coil market directly impacts pricing. Factors such as global mill production rates, scrap metal prices, and the cost of nickel and chromium influence these changes. Additional variables like import tariffs and international shipping costs also affect bulk order pricing.

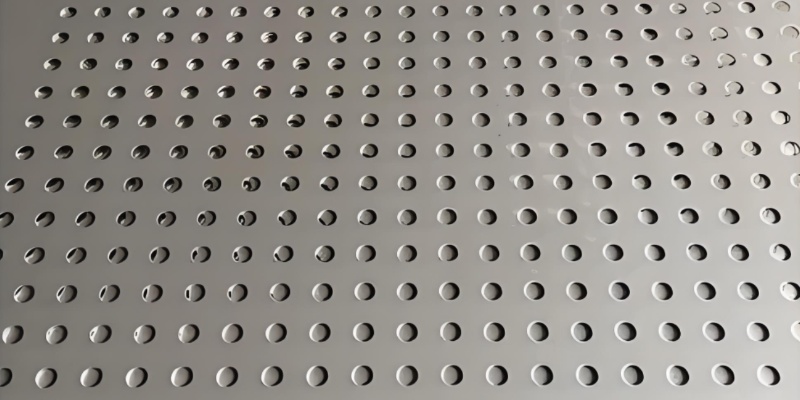

3. Perforation Rate and Material Utilization

The perforation rate refers to the percentage of the sheet surface that is perforated. A higher perforation rate leads to more material waste and higher recycling costs. It also requires frequent machine adjustments, which extends production time and raises manufacturing expenses. A medium perforation rate of 20%–40% is often ideal to balance efficiency and material usage.

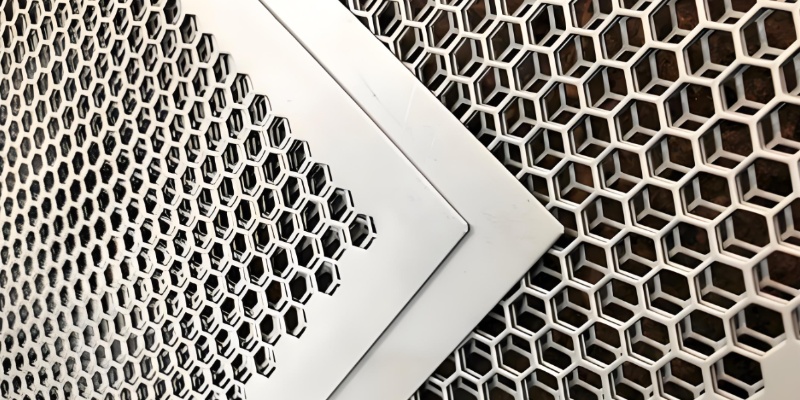

4. Hole Shape, Size, and Layout

The choice of hole shape directly impacts both aesthetics and production complexity:

Standard round, square, and slotted holes are economical due to mature processes.

Complex shapes like gradient patterns, concentric circles, and diamonds require precise positioning and custom tooling, raising production costs.

Layout styles such as 45°/60° staggered or 90° straight rows also affect sheet strength and perforating speed, subtly influencing the quote.

5. Sheet Thickness and Dimensions

Thickness ranges from 0.3mm to 10mm.

Thicker sheets use more material and place greater load on machinery, increasing cost per square meter.

Ultrathin sheets (<0.5mm), while lightweight, are harder to process and prone to deformation, requiring higher precision and also increasing costs.

Common dimensions like 1220×2440mm or 1250×2500mm meet most usage needs. Custom widths or oversized sheets involve additional cutting and logistics costs.

6. Processing Method and Equipment Selection

Traditional punch press: Best for high-volume, standard-hole production with lower unit cost.

CNC punching: Reduces machine setup time for multi-pattern jobs, offering mid-range pricing.

Laser cutting: Delivers complex designs and high precision, ideal for thick or irregular pieces, but comes with higher depreciation and energy costs.

Drilling: Suited for small-batch or non-standard hole sizes. It's slower and labor-intensive, resulting in higher pricing.

Choosing the right equipment ensures quality while optimizing overall sheet production costs.

7. Surface Treatment

Surface treatments enhance both the appearance and corrosion resistance of stainless steel perforated sheets. Common options include:

Brushed / Sandblasted: Removes minor imperfections for a clean look.

Electropolished: Boosts shine and reduces internal stress, extending sheet life.

PVDF Coating: Offers superior outdoor weather resistance but requires additional material and spraying costs.

The more complex the finishing process, the more material and labor are needed—raising the final price accordingly.

8. Order Volume and Delivery Time

Large volume orders allow for cost distribution over tooling and setup, resulting in a more competitive unit price. Conversely, small or sample orders can't absorb these fixed costs, leading to higher pricing. Rush orders may require overtime or outsourced production, adding extra fees.

9. Customization and Technical Support

Special needs such as component assembly, decorative laser patterns, welded brackets, or prototype testing fall under custom services. These tailored processes meet unique project demands but also add technical and labor costs that are reflected in the quotation.

The price of stainless steel perforated sheets is influenced by multiple interconnected factors including material grade, market conditions, perforation rate, hole type, thickness, processing technology, surface treatment, order quantity, and custom requirements. To obtain an accurate quote, please prepare the following:

Desired material grade (e.g., 304, 316, or specialty alloys)

Sheet thickness and dimensions

Expected perforation rate and hole layout

Required surface treatment

Order volume and lead time

Any custom processing or technical support needs

Contact us: Send your specifications to 342096438@qq.com and we'll provide a professional, accurate quote within 24 hours. We look forward to collaborating on high-quality stainless steel perforated sheet solutions!