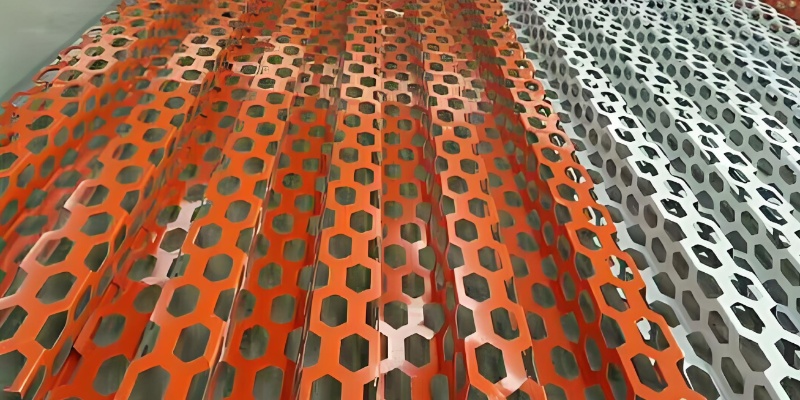

Comprehensive Guide to Common Materials for Perforated Metal Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-05-26 14:32:05 Browse:

Perforated Metal Sheets have become essential materials in various industries including architectural decoration, industrial screening, mechanical protection, and sound insulation. Below is an analysis of several commonly used materials in perforated sheets, offering reference for material selection:

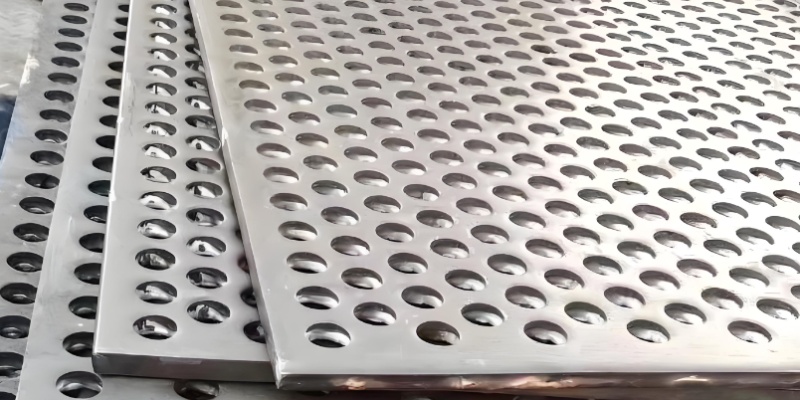

Stainless steel perforated sheets are widely used in outdoor settings, high-humidity areas, and the chemical industry due to their excellent corrosion resistance, high strength, and aesthetic appeal. Surface treatments such as electro-polishing, brushing, and coating not only enhance appearance but also improve hardness and impact resistance. Food-grade stainless steel perforated sheets are also suitable for food processing environments.

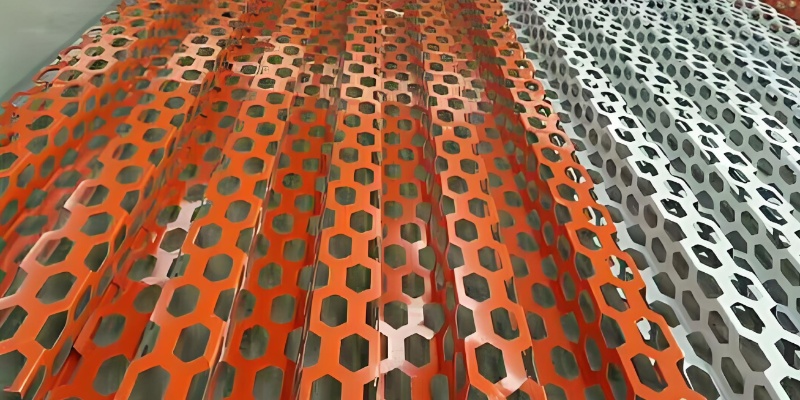

Aluminum alloy perforated sheets are known for being lightweight yet strong, corrosion-resistant, and highly workable. Their low density makes them easy to transport and install, especially suitable for high-rise buildings or ceiling systems. The natural oxide layer on the surface provides great protection against corrosion, and further surface treatments like anodizing, painting, or electrophoresis can enhance both appearance and durability. These sheets are commonly used in facade cladding, ceilings, ventilation systems, and signage.

Galvanized Steel Perforated Sheets

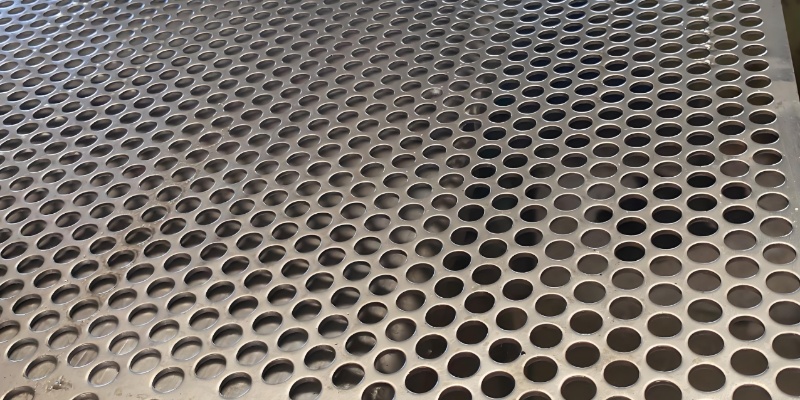

Galvanized steel perforated sheets are cost-effective, durable, and offer strong rust resistance, making them ideal for large-scale industrial applications. The zinc coating effectively prevents rusting and extends service life, especially in humid environments. With higher tensile strength compared to aluminum, they are widely used in industrial safety, machine guards, screening, fencing, and ventilation equipment.

Hot-rolled steel perforated sheets offer high strength, excellent impact resistance, and lower costs. Their heat-treated structure ensures superb shock absorption and deformation resistance. Although the surface is relatively rough, it’s easy to coat but requires anti-corrosion treatment. They are ideal for machinery manufacturing, bridge construction, steel structures, and industrial equipment.

Manganese steel perforated sheets are ideal for heavy-load applications due to their wear resistance, impact resistance, and compression strength. With 11–14% manganese content, they undergo “work hardening” upon impact, increasing surface hardness. They are commonly used in mining equipment, screening meshes, wear-resistant liners, and construction machinery.

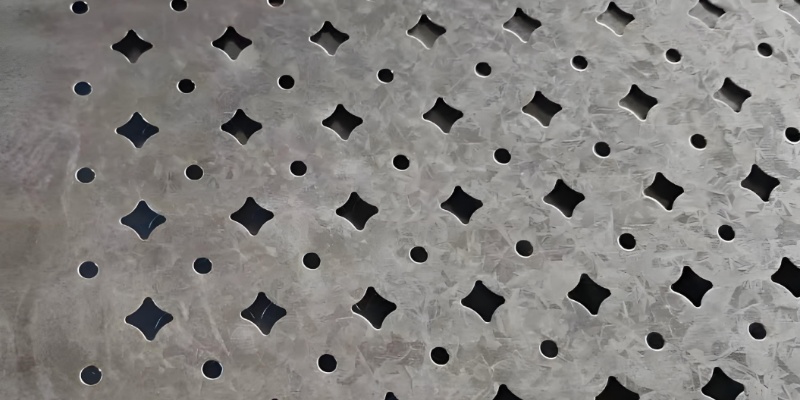

Cold-rolled steel perforated sheets feature smooth surfaces and high dimensional accuracy, making them suitable for applications requiring superior surface quality. They offer excellent processability for cutting, punching, and bending. These sheets are widely used in appliance enclosures, office furniture, and interior decoration.

Selecting the right Perforated Metal Sheets material should be based on specific application requirements, with a balanced consideration of each material’s performance characteristics to achieve the best usage outcomes.