Product Types & Manufacturing Processes

Two Galvanizing Methods

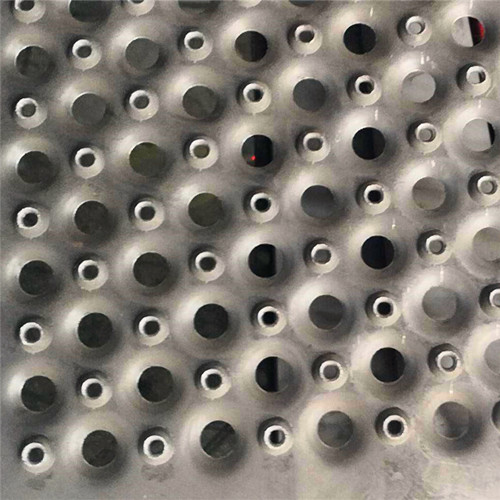

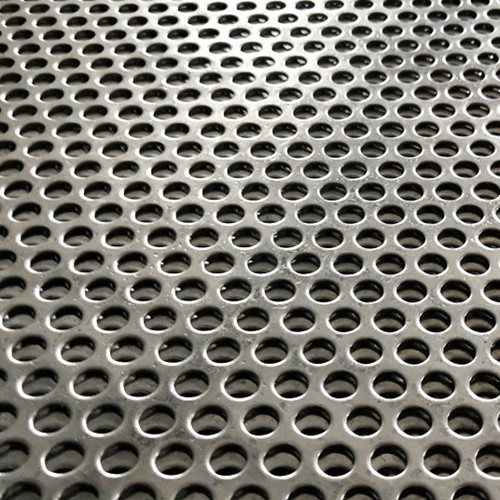

1.Pre-Galvanized Perforated Sheet

Manufactured from pre-coated galvanized steel sheets

Moderate zinc layer thickness with excellent cost-effectiveness

Ideal for standard architectural and decorative uses in normal environments

2.Post-Galvanized Perforated Sheet

Perforated first, then hot-dip galvanized for superior corrosion resistance

Thicker zinc coating ensures long-term durability

Recommended for harsh conditions (e.g., coastal areas, high humidity)

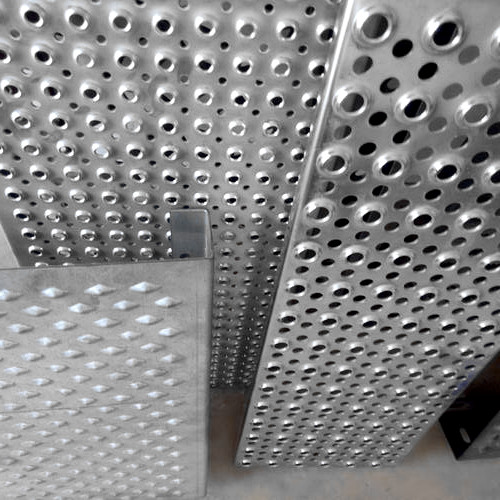

Technical Specifications

Basic Parameters

Material Options: Low-carbon steel, medium-carbon steel

Thickness Range: 0.3mm–20mm (coil: 0.3mm–1mm)

Standard Sizes:

1000mm × 2000mm

1250mm × 2500mm

1500mm × 3000mm

Custom Sizes: Width 50mm–1500mm, Length 50mm–6000mm

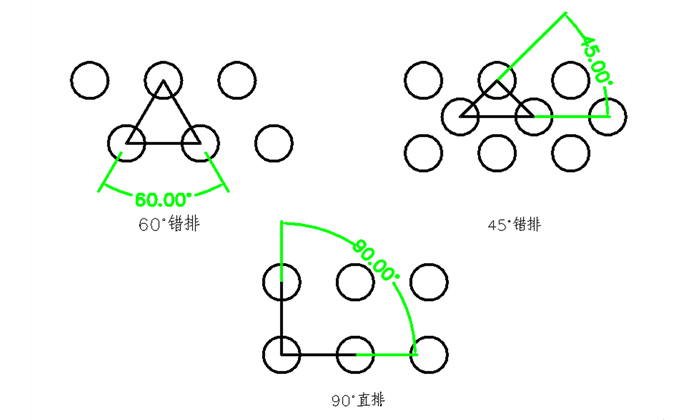

Hole Patterns & Arrangement

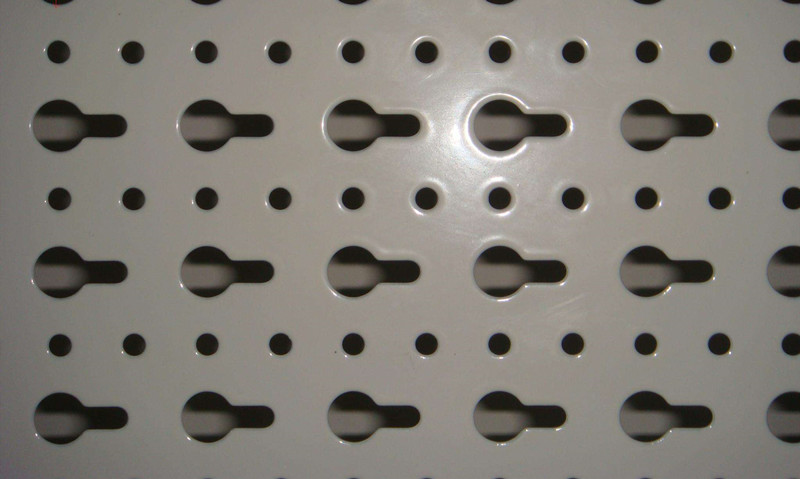

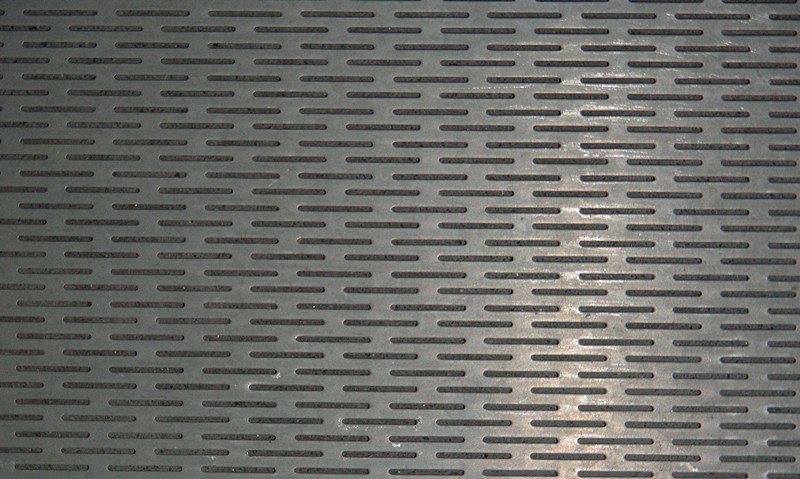

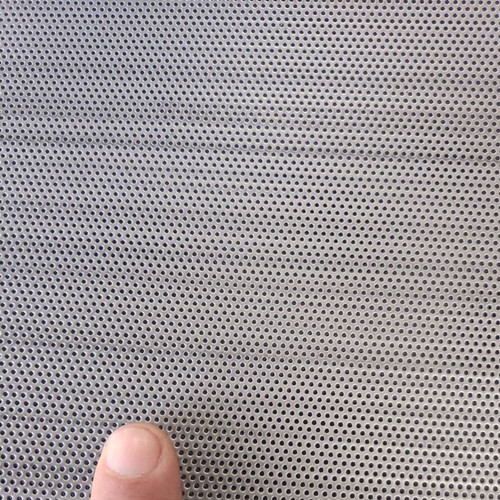

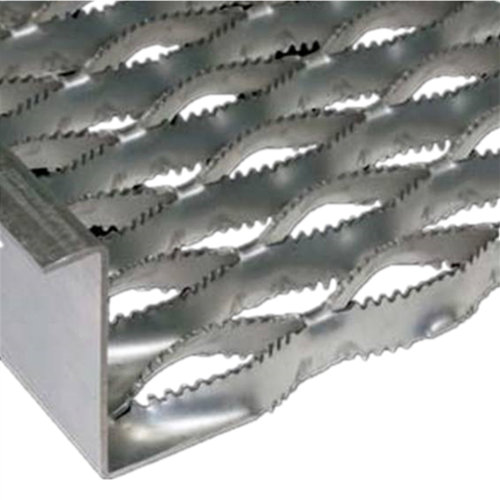

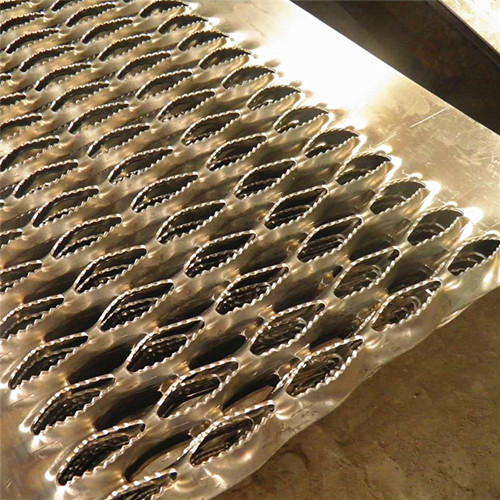

Common Hole Types: Round, square, hexagonal, fish-scale, diamond, bridge-type

Hole Diameter Range: 0.4mm–300mm (adjustable)

Layout Options: 60° staggered, 45° staggered, 90° straight

Key Advantages

Performance Benefits

Weather Resistance – Extended service life due to zinc protection

Multi-Functionality – Ventilation, light penetration, noise reduction

Structural Strength – Maintains load-bearing capacity despite perforations

Easy Installation – Lightweight with multiple fixing methods

Customization Services

Non-standard hole shapes & unique pattern designs

Precision machining based on engineering drawings

Sample approval before mass production

Applications

Architectural Decoration

Building façade sunshades

Indoor/outdoor partitions & ceiling decor

Stair treads & balcony railings

Industrial Equipment

Machinery protective covers

Screening & filtration systems

Warehouse ventilation panels

Municipal Projects

Highway sound barriers

Subway platform acoustic walls

Urban drainage covers

Household & Commercial Uses

Kitchen drain racks

Furniture decorative panels

Landscaping elements