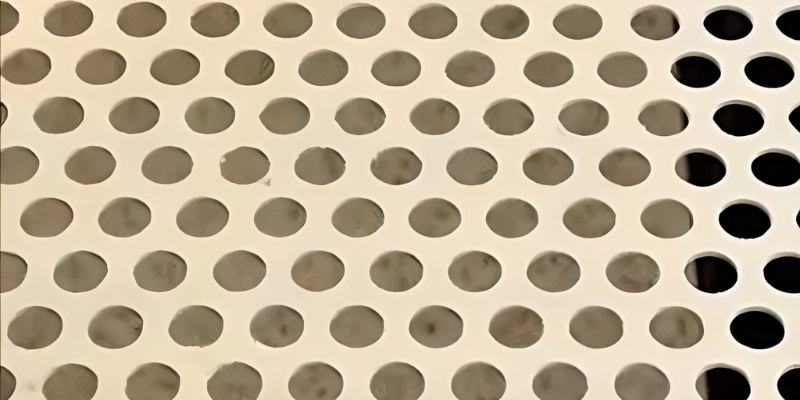

7. Surface Quality Examination

Inspect the surface for defects such as scratches, burrs, or rust. Confirm that surface treatments (polishing, coating, galvanizing) meet quality standards. Proper surface finishing improves durability, corrosion resistance, and appearance.

8. Edge Finish Evaluation

Examine edges to ensure smoothness without burrs or cracks. Edge quality affects installation safety and overall product aesthetics, so careful processing and inspection are necessary.

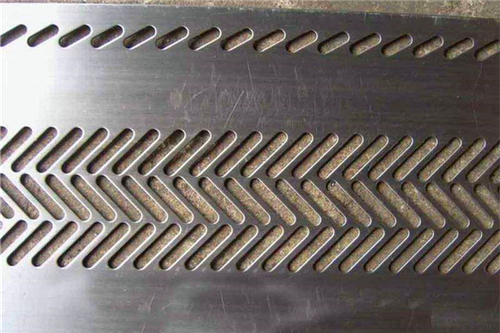

9. Additional Testing Options

Additional tests may include:

Bending and Deformation Testing: To ensure flatness and avoid warping during installation.

Durability Testing: To assess impact resistance and wear performance for long-term use.

Appearance Consistency: Batch inspections for mass-produced sheets to maintain uniform look and quality.

Following these comprehensive evaluation steps allows manufacturers and users to ensure the quality of perforated sheets meets high standards. As a professional manufacturer specializing in perforated sheets, we strictly implement these quality controls to provide superior products and reliable service.