Household Items

Used in kitchen baskets, food covers, and storage racks, these sheets add both convenience and a modern touch to domestic interiors. Their strength and ease of cleaning make them ideal for daily use.

Through flexible design and adaptable functionality, perforated sheets continue to find new use cases across evolving markets and lifestyles.

Core Advantages and Future Development of Perforated Metal Sheets

Key Advantages:

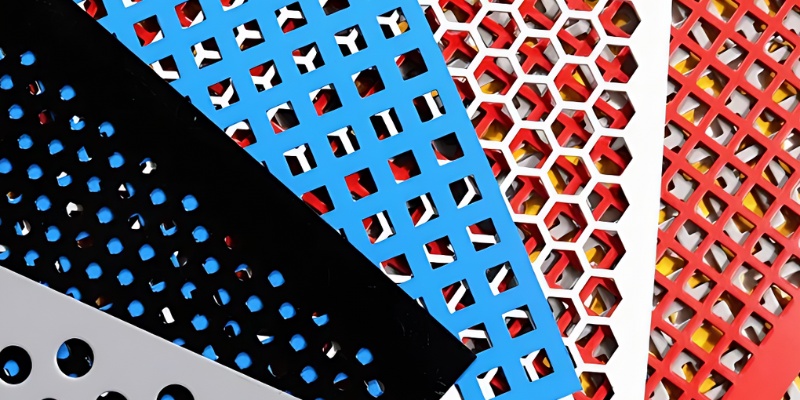

Highly Customizable:

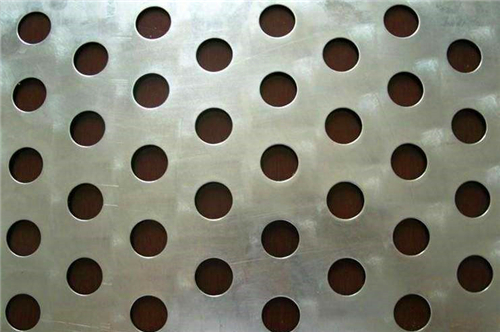

Available in various materials, thicknesses, hole sizes, and patterns to meet the demands of different applications.

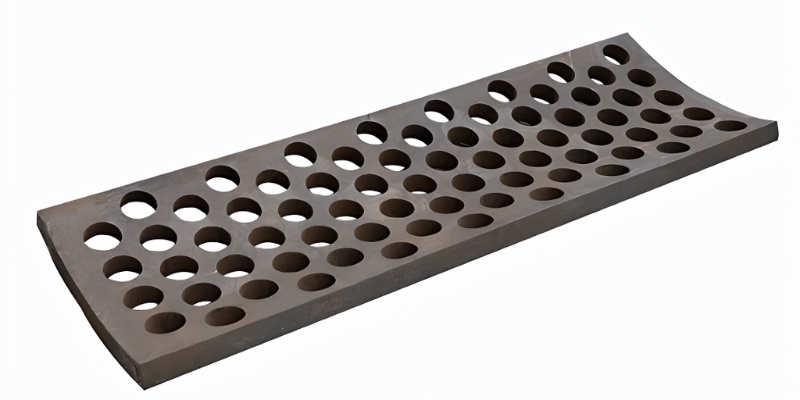

Durable and Reliable:

Made from high-quality materials such as stainless steel, aluminum, and galvanized steel, offering excellent corrosion, pressure, and wear resistance.

Eco-Friendly and Energy-Efficient:

Used in soundproofing, heat dissipation, and filtration systems, perforated metal sheets contribute to better energy usage and reduced environmental impact.

Lightweight and Easy to Install:

Their low weight and modular design simplify transportation, installation, and maintenance—reducing overall project costs.

Development Trends:

Smart and Precise Customization:

With advanced technologies like CAD, laser cutting, and digital modeling, perforated sheets are becoming more precisely manufactured to fit specific design and performance needs.

Sustainable Manufacturing:

Driven by global sustainability goals, the industry is moving towards greener production processes and recyclable materials.

New Materials and Composite Applications:

Innovations in materials and nanotechnology will enable perforated sheets to enter advanced sectors such as aerospace, renewable energy, and smart manufacturing.

Conclusion

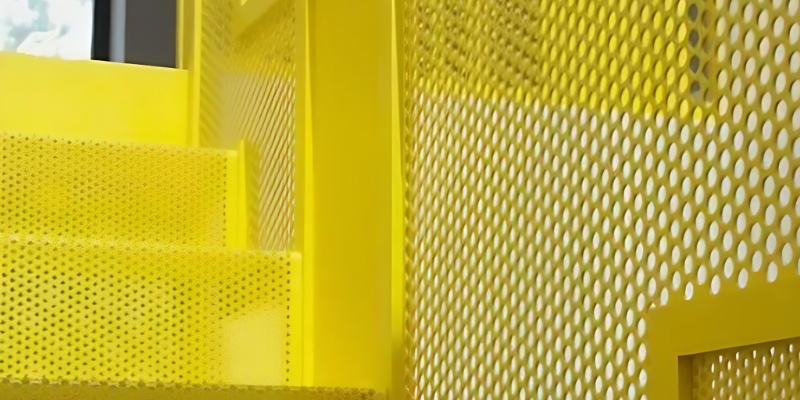

Perforated metal sheets, thanks to their unique hole structure and diverse use cases, are now indispensable across various sectors. From enhancing architectural aesthetics and reducing noise pollution to enabling precise industrial filtration and enriching everyday life, their functionality continues to expand.

As technology evolves and market demand grows, perforated metal sheets are set to play an even more vital role in shaping the future of industry and innovation. We are committed to delivering high-performance, cost-effective perforated metal solutions and invite all partners to explore new possibilities with us.

Looking for reliable, customizable perforated metal sheet solutions?

Contact us today for expert consultation and high-quality support.