2. Thickness of Perforated Sheets

Perforated sheets typically range in thickness from 0.5mm to 20mm. The thickness should be chosen based on the specific application:

Thin Sheets (0.5mm - 1.5mm): Suitable for light decorative, filtration, and acoustic applications.

Medium Sheets (2mm - 5mm): Common in mechanical protection, ventilation barriers, and structural applications.

Thick Sheets (6mm and above): Used in heavy industrial applications, screening equipment, and protective enclosures.

It is important to note that the hole diameter should not exceed the sheet's thickness to ensure the quality of the perforation.

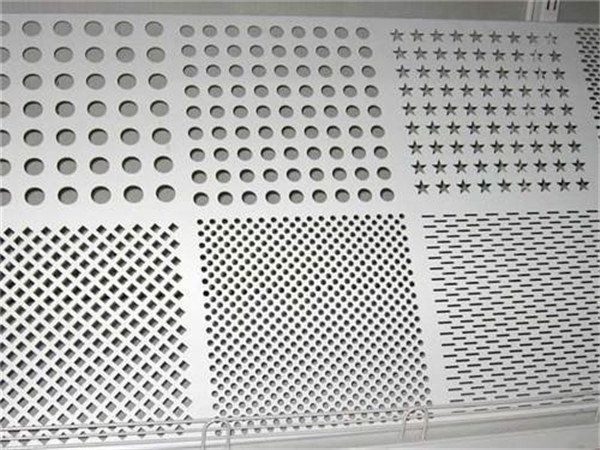

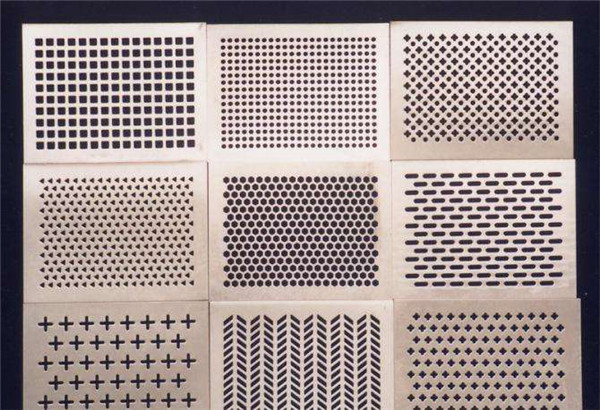

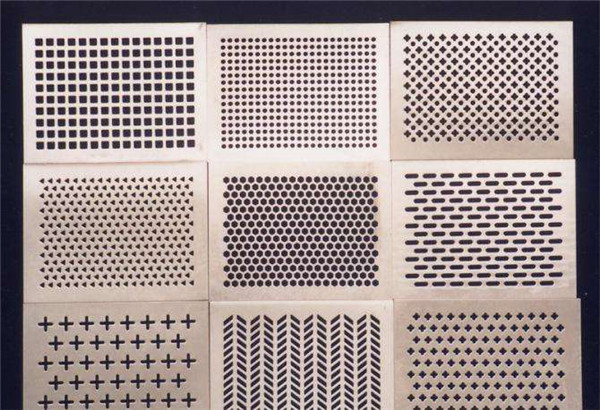

3. Hole Shapes of Perforated Sheets

Perforated sheets come in a wide range of hole shapes, designed to meet both functional and aesthetic needs. Common hole shapes include:

Basic Hole Shapes: Round holes, oval holes, elongated holes, which are the most commonly used.

Square and Rectangular Holes: Ideal for filtration and screening with high hole space utilization.

Triangular, Star, and Plum Blossom Holes: Often used for decorative and artistic designs.

Hexagonal Holes, Oblique Holes, Cross-Shaped Holes: Provide unique visual effects and functionality.

Fish Scale Holes, Louver Holes, Crocodile Mouth Holes, Raised Circular Holes: Offer specialized features like drainage, anti-slip, and soundproofing.

Custom-shaped holes can also be designed based on specific functional and design requirements.

4. Hole Diameter of Perforated Sheets

The diameter of perforated holes ranges from 0.5mm to 200mm. The selection of hole diameter depends on factors such as airflow, filtration, and visual aesthetics:

Air or Liquid Permeability: Larger hole diameters are used for better airflow and filtration.

Mechanical Protection: Smaller hole diameters are more suitable for safety and protective applications.

Aesthetic and Concealment: Decorative perforated sheets often use densely packed small holes to create visual patterns.

Generally, the hole diameter should not be smaller than the thickness of the sheet to ensure the quality and longevity of the perforation.

5. Hole Pitch and Arrangement

The pitch (the distance between the centers of two adjacent holes) and hole arrangement directly impact the strength, appearance, and functionality of perforated sheets. Common hole arrangements include:

60° Staggered: Aesthetic and widely used in decorative applications.

45° Staggered: Provides an orderly layout, commonly used in filtration and screening.

90° Straight: Neat and easy to process, often used in industrial applications.

Irregular Arrangements: Used for artistic, acoustic, and custom decorative designs.

The hole pitch is generally not less than the sheet thickness to maintain the structural integrity of the perforated sheet.

6. Overall Dimensions of Perforated Sheets

The most common overall dimensions for perforated sheets are:

1.0 Meter × 2.0 Meters

1.2 Meters × 2.4 Meters

We also offer custom sizes to meet specific installation and operational needs. Perforated sheets can be tailored to suit the requirements of various industries and applications.

Why Choose Senchi Metal Perforated Sheets?

Anping Senchi Metal Wire Mesh Products Co., Ltd. is equipped with advanced perforating equipment and has extensive experience in custom production. We provide high-quality perforated sheets for industries ranging from architecture and machinery to environmental protection and noise control. Whether you require large-scale production or bespoke solutions, we are committed to offering the most cost-effective and professional products and services.

Feel free to contact us for a consultation or to submit custom drawings for your specific needs.