Key Features and Advantages of Perforated Panels as Protective Screens

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-08 11:42:08 Browse:

As safety protection and aesthetic design demands in modern industry, architecture, and transportation continue to rise, perforated panels have increasingly become a popular choice. Thanks to their unique structural design and excellent performance, perforated panels demonstrate wide-ranging value in various protective applications. This article systematically outlines the core features and advantages of perforated panels used as protective screens, providing an in-depth understanding of this innovative material.

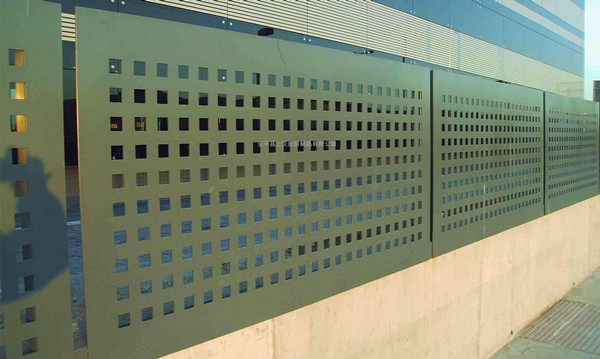

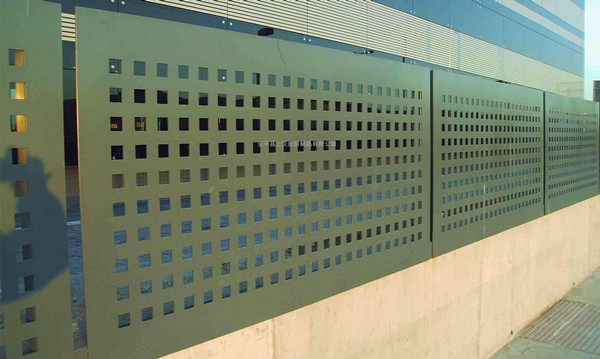

1. Diverse Design Styles and Unique Visual Appeal

Perforated panels are created by punching various shapes of holes into metal sheets, forming diverse patterns. Common hole shapes include round, square, elongated, triangular, and hexagonal, as well as more creative designs such as plum blossom or fish scale holes. These hole patterns not only meet functional requirements for ventilation and protection but also greatly enhance the material’s aesthetic appeal.

This design diversity allows perforated panels to be flexibly applied in building facades, partition fences, and machinery protection. Whether in modern architectural decoration or industrial safety barriers, perforated panels seamlessly integrate into the environment, enhancing the overall artistic and contemporary feel of spaces.

2. Excellent Structural Strength and Safety Protection

Perforated panels are typically formed by numerically controlled stamping of entire metal sheets, avoiding structural weaknesses caused by welding seams. This results in higher overall strength and greater structural stability compared to traditional welded protective meshes. The thickness and hole size can be customized to ensure resistance to external impacts.

In terms of safety protection, the high strength of perforated panels guarantees long-term stability without deformation, effectively preventing damage from accidental collisions or impacts. Additionally, properly designed hole sizes can block small animals or foreign objects, providing multiple layers of safety protection.

3. Superior Corrosion Resistance and Long Service Life

Materials commonly used for perforated panels include high-quality stainless steel, aluminum alloy, or hot-dip galvanized steel sheets, all of which inherently possess excellent corrosion resistance. Furthermore, surface treatments such as spraying, powder coating, and anodizing enhance the panels’ ability to resist oxidation and corrosion.

Whether in humid coastal environments with high salt spray or in industrial zones with dust and moisture, perforated panels maintain a clean surface and extended lifespan. This durability not only reduces maintenance costs but also ensures consistent protective performance over time.

4. Outstanding Ventilation and Light Transmission

One of the biggest advantages of perforated panels is their hole structure, which provides excellent ventilation and light transmission. Air can freely flow through the holes, preventing heat buildup and moisture stagnation in enclosed spaces.

This feature makes perforated panels ideal for areas requiring airflow, such as high-rise building railings, equipment rooms, and parking lot fences. The light transmission improves lighting conditions and facilitates security monitoring to some extent.

5. Flexible Customization and Wide Application Range

Perforated panels can be customized in hole size, shape, sheet thickness, and overall dimensions according to project requirements, achieving a high degree of design and functional integration. Processing methods include stamping and laser cutting, meeting various complexity levels.

In practice, perforated panels are widely used in building curtain walls, road traffic barriers, industrial equipment protection, safety fences, and ventilation covers. Combining practicality with aesthetics, they have become an indispensable material in modern safety protection and architectural decoration.

Conclusion

In summary, perforated panels as protective screens excel not only in structural safety and durability but also offer unique design aesthetics and superior ventilation. With a wide variety of hole shapes and flexible customization options, perforated panels meet diverse industrial and architectural protection needs, making them an ideal choice for modern protective materials. As technology advances and application demands increase, perforated panels will continue to demonstrate greater potential and value across multiple fields.